5 Installation at Site

16 of 88

BoosterControl Advanced

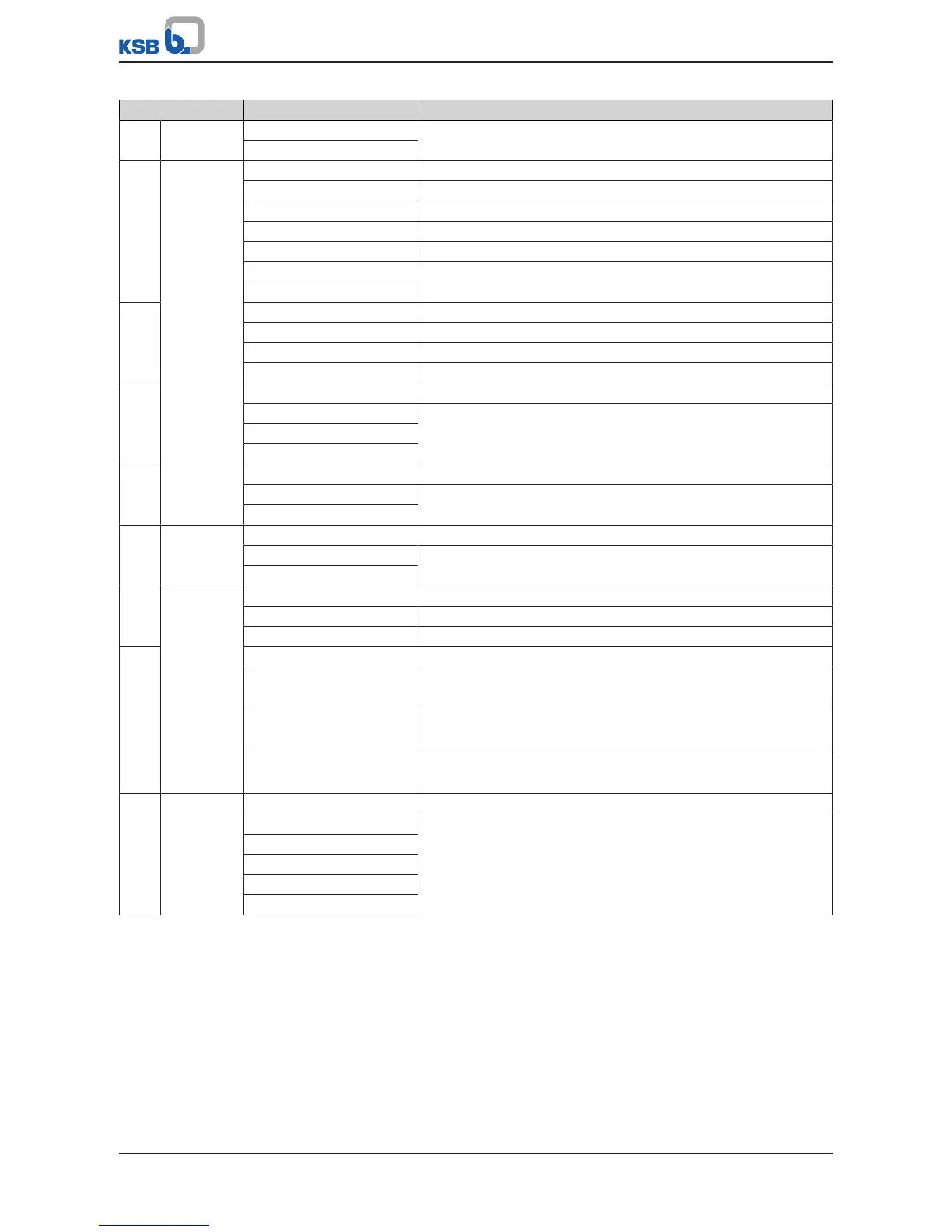

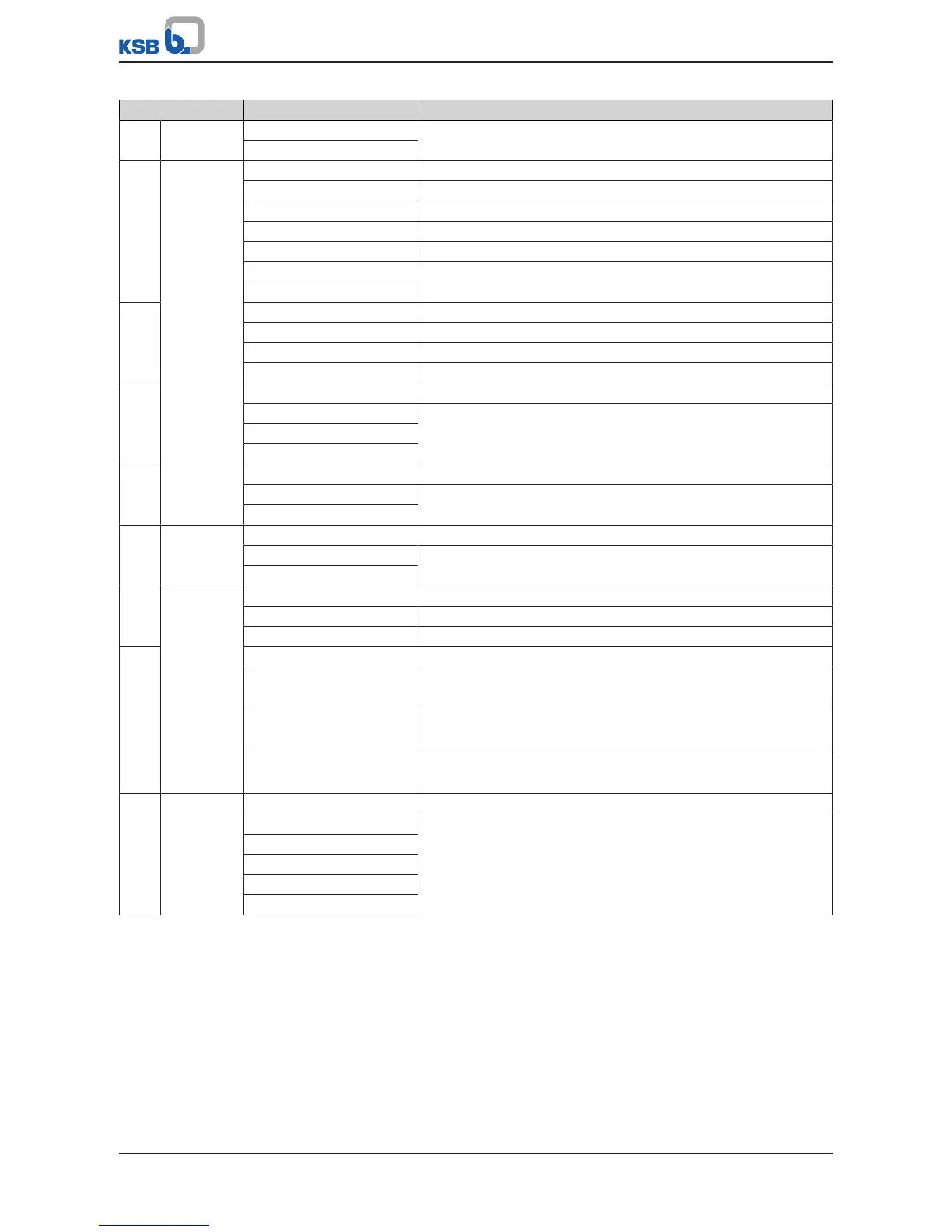

Terminal strip Terminal Description

8 J405 PT inl + Pressure sensor, suction side

PT inl -

9 J403 Digital inputs

RDP Pressure switch for dry running protection

TFO Fault reporting relay of frequency inverter

TVA Fault reporting relay of valve

OFF External OFF switch

FIRE Fire alert

COM Digital inputs - 24 V DC supply

10 Fault input, pump set

P1 Motor protection/thermal overload, pump 1

P2 Motor protection/thermal overload, pump 2

P3 Motor protection/thermal overload, pump 3

11 J302 Can bus (RS 485)

B RS485 bus for frequency inverter

A

GND

12 J501 Proportional valve for inlet tank

+ Proportional valve for inlet tank

-

13 J502 Setpoint signal, analog

+ Setpoint for floating frequency inverter

-

14 J401 Temperature sensor for water flow detection

PT1000 - Temperature sensor - earth

PT1000 + Temperature sensor - signal

15 Water flow detector for detecting water flow

WSD1 Water flow detector sensor 1

Parameterisable input 1

WSD2 Water flow detector sensor 2

Parameterisable input 2

WSD3 Water flow detector sensor 3

Parameterisable input 3

16 J301 CAN-Open

GND CAN bus

H

L

T-

T+

Connections on the expansion board (maximum of 6pumps)

The BoosterControl Advanced version for 6pumps is equipped with additional

terminals in the centre area at the rear of the control system (cannot be retrofitted;

factory-set).

Terminals P4 - P6 are used to connect the freely parameterisable outputs.

Loading...

Loading...