8 Commissioning/Start-up/Shutdown

45 of 88

BoosterControl Advanced

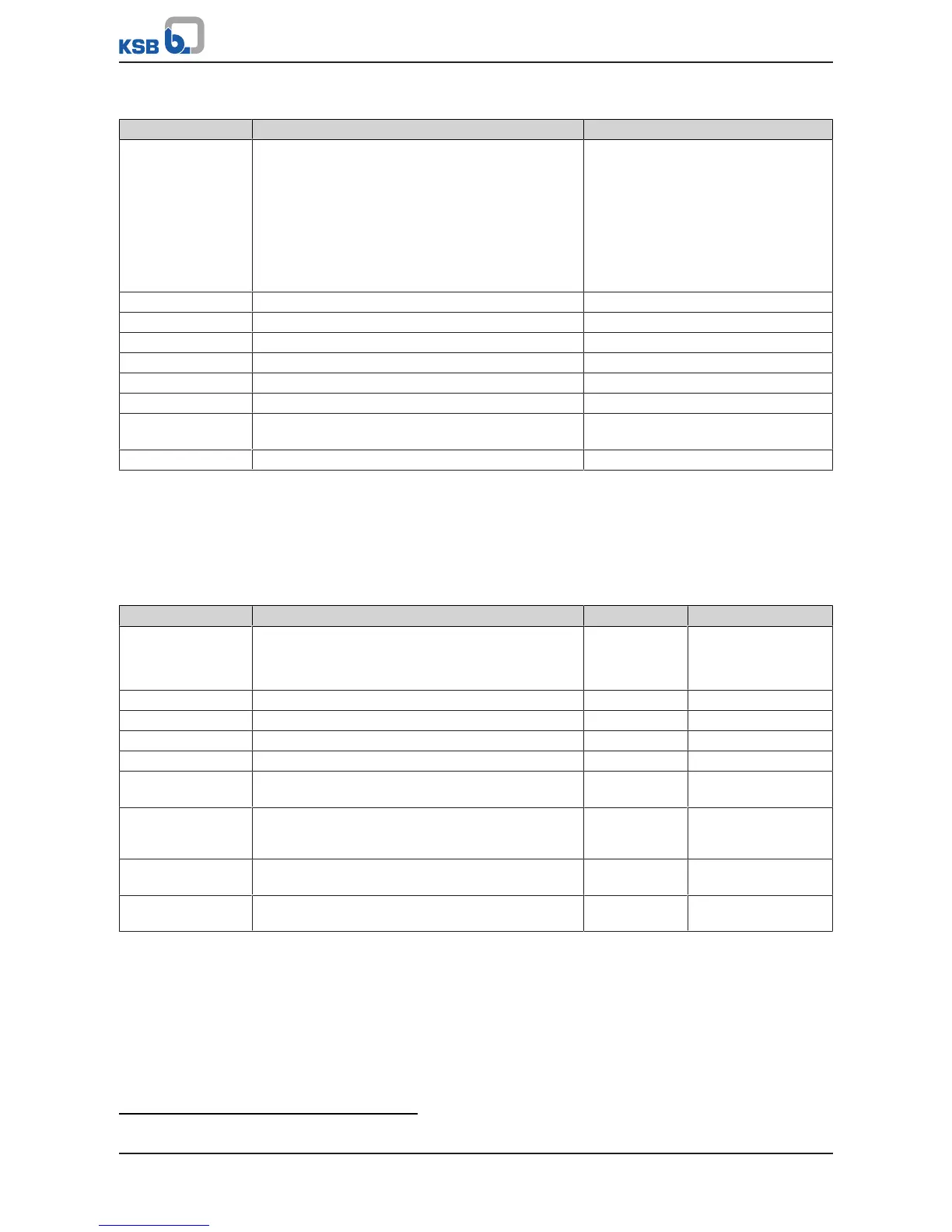

Table34: Frequency inverter parameter settings for control with one frequency inverter

Parameter Description Possible values

3-4-3-1 Communication protocol of frequency inverter None

Analog 0 - 20 mA

Analog 4 - 20 mA

PumpDrive

Danfoss MicroDrive

Danfoss VLT2800

Danfoss AquaDrive

3-4-3-2 Proportional constant of PID controller 0...100

3-4-3-3 Integral constant of PID controller 0...60s

3-4-3-4 Differential constant of PID controller

12)

0...99s

3-4-3-9 Start ramp of frequency inverters 0 ... 999 s

3-4-3-10 Stop ramp of frequency inverters 0 ... 999 s

3-4-3-11 Minimum frequency of frequency inverters 0 ... 50 Hz

3-4-3-12 Maximum frequency of frequency inverters 0 ... 50 Hz (60 Hz for Danfoss

MicroDrive)

3-4-3-15 Nominal frequency of frequency inverters 0 ... 50 Hz

8.5 Application functions

BoosterControl Advanced has many useful features that are described in this section:

8.5.1 Setting the parameters for dry running protection

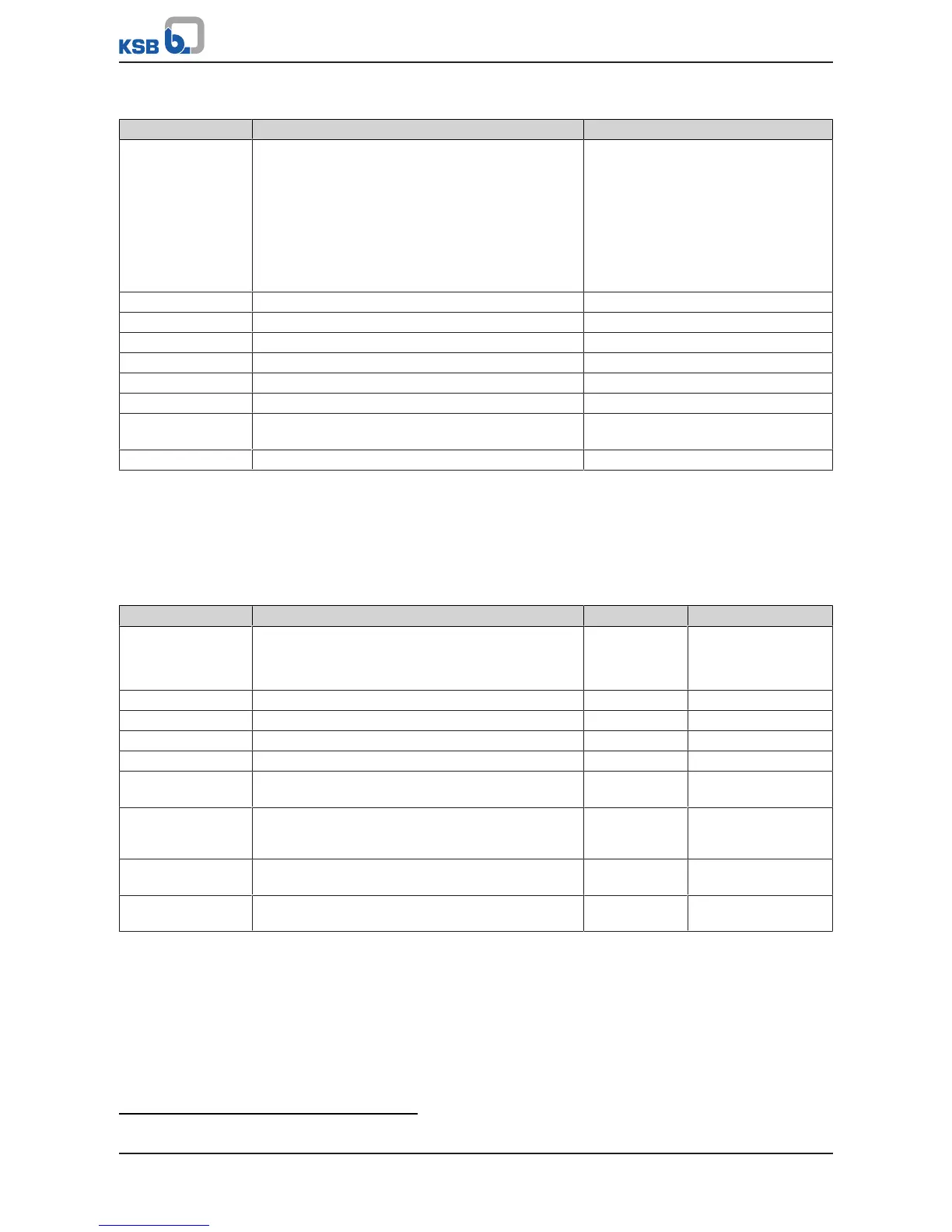

Table35: Parameter settings for dry running protection

Parameter Description Default Possible values

3-3-2 Configuration of suction side

BoosterControl Advanced reboots; observe notes

Setting of suction-side pressure transmitter

- Pressure switch

Pressure sensor

Flow monitoring

3-4-1-1 Calibrate suction-side pressure sensor at 4mA 0 kPa -1 ... 99,99 Bar

3-4-1-2 Calibrate suction-side pressure sensor at 20 mA 1000 kPa 0 ... 99,99 Bar

3-4-2-1 Calibrate discharge-side pressure sensor at 4mA - -1...99,99 Bar

3-4-2-2 Calibrate discharge-side pressure sensor at 20 mA - 0...99,99 Bar

3-5-15 Minimum pressure before dry running protection is

activated

- 0 ... 1000 kPa

3-5-16 Minimum pressure before system restarts after

having been tripped by dry running protection

device

- 0 ... 1000 kPa

3-6-8 Stop delay for system tripped by dry running

protection device

- 0 ... 10 s

3-9 Deactivate the "No water" message in the field list

(then the fault is self-acknowledging)

- -

If a pressure switch is used as a dry running protection device, also set the following

parameters.

8.5.2 Setting an alternative setpoint

If a second setpoint is required at certain times, an alternative setpoint can be set.

The alternative setpoint can be activated either once a day or once a week. Non-

relevant parameters are automatically hidden.

12) The differential constant is always zero.

Loading...

Loading...