MAINTENANCE WORK ON CHASSIS AND ENGINE 66

B00042-10

– Inject the liquid into the system until it escapes from hole of the master

cylinder without bubbles.

– To prevent overflow, drain fluid occasionally from the master cylinder reservoir.

– Remove the bleeding syringe. Mount and tighten the bleeder screw.

– Correct the fluid level of the hydraulic clutch.

Guideline

Fluid level under top edge of con-

tainer

4 mm (0.16 in)

– Position the cover with the membrane. Mount and tighten the screws.

9.97Checking the basic position of the shift lever

400692-10

– Sit on the vehicle in the riding position and determine the distance between the

upper edge of your boot and shift lever .

Distance between shift lever and upper

edge of boot

10… 20 mm (0.39… 0.79 in)

» If the distance does not meet specifications:

–

Adjust the basic position of the shift lever. x ( p. 66)

9.98Adjusting the basic position of the shift lever x

B00065-10

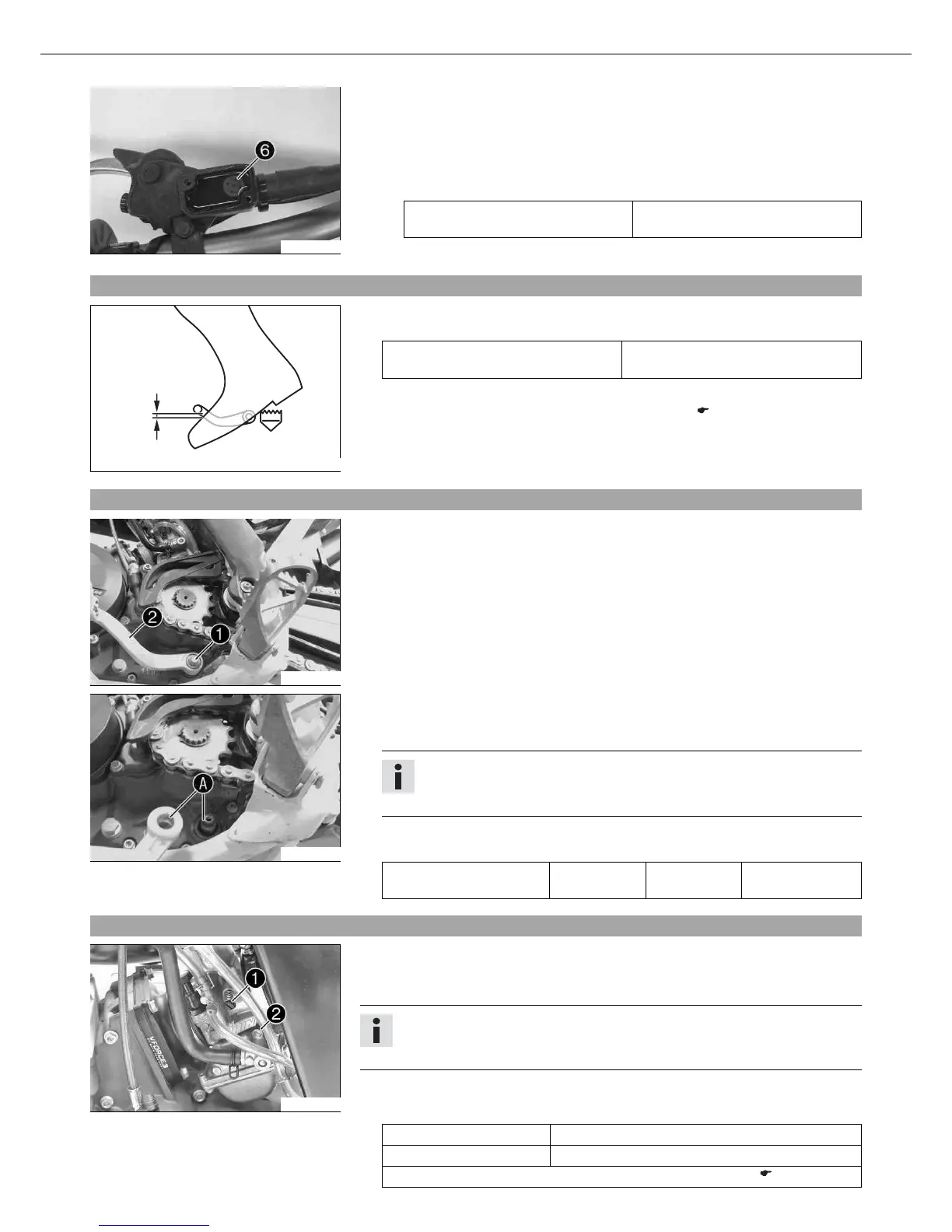

– Remove screw and remove shift lever .

B00066-10

– Clean gear teeth of the shift lever and shift shaft.

– Mount the shift lever on the shift shaft in the required position and engage the

gearing.

Info

When positioning the shift lever, ensure that there is sufficient distance to

the adjacent components.

– Mount and tighten the screw.

Guideline

Screw, shift lever M6 14 Nm

(10.3 lbf ft)

Loctite

®

243™

9.99Carburetor

B00048-11

The idle setting of the carburetor has a big influence on the starting behavior, idling

stability and the response to opening of the throttle. An engine with a correctly set idle

speed is easier to start than if the idle is set wrongly.

Info

The carburetor and its components are subject to increased wear caused by

engine vibration. Wear can result in malfunctioning.

The carburetor factory settings are as follows.

(125 SX, 150 SX)

Altitude above sea level 500 m (1,640 ft)

Ambient temperature 20 °C (68 °F)

Super unleaded gasoline, mixed with 2-stroke engine oil (1:40) ( p. 95)