13. FUEL SYSTEM/CARBURETOR/

FUEL PUMP/ FUEL TANK

13-16

GRAND DINK 250

FLOAT LEVEL INSPECTION

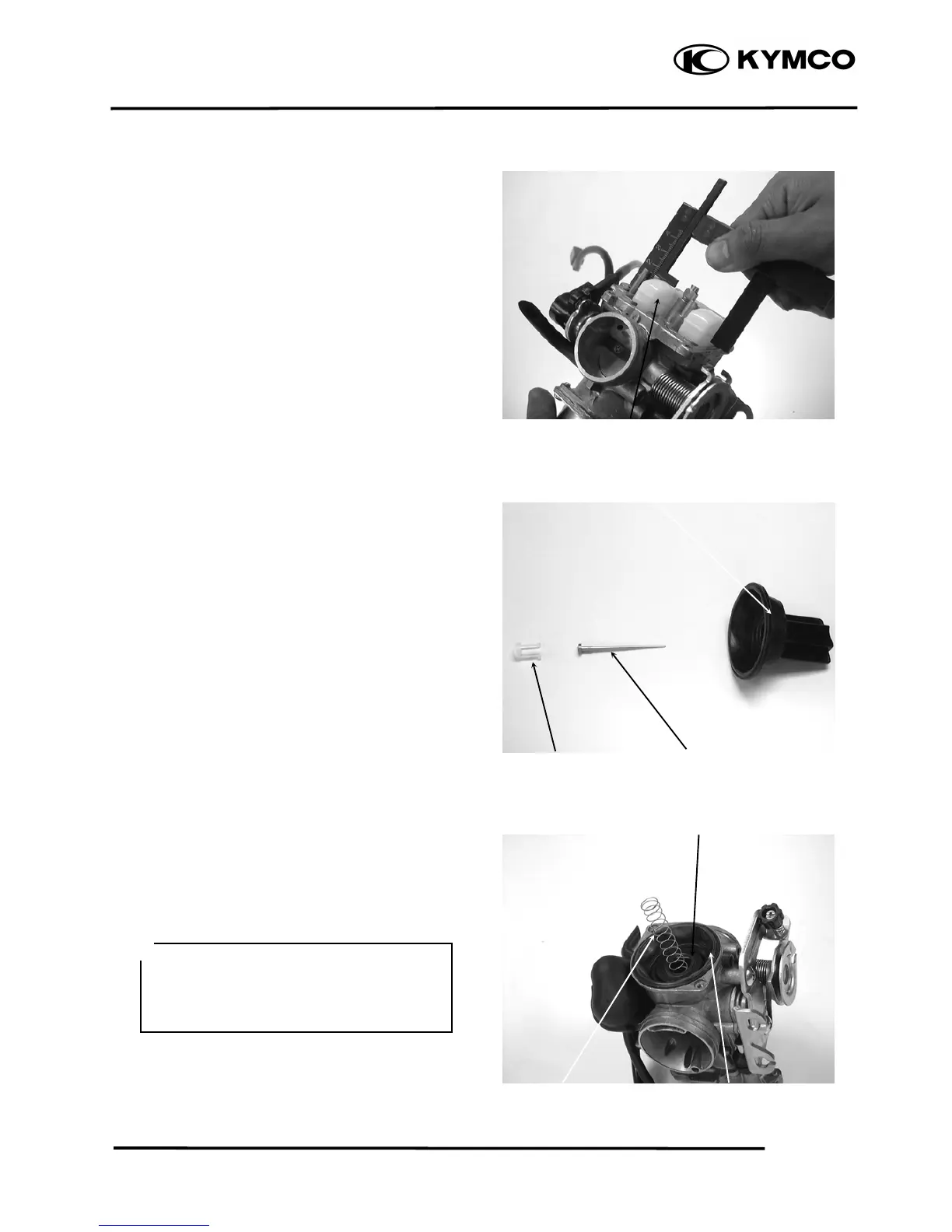

Measure the float level at the location of the

main jet (just contacting the float valve).

Float Level: 18.5±1.0mm

Replace the float if the level is incorrect.

Check the operation of the float and then

reinstall the float chamber.

VACUUM CHAMBER ASSEMBLY

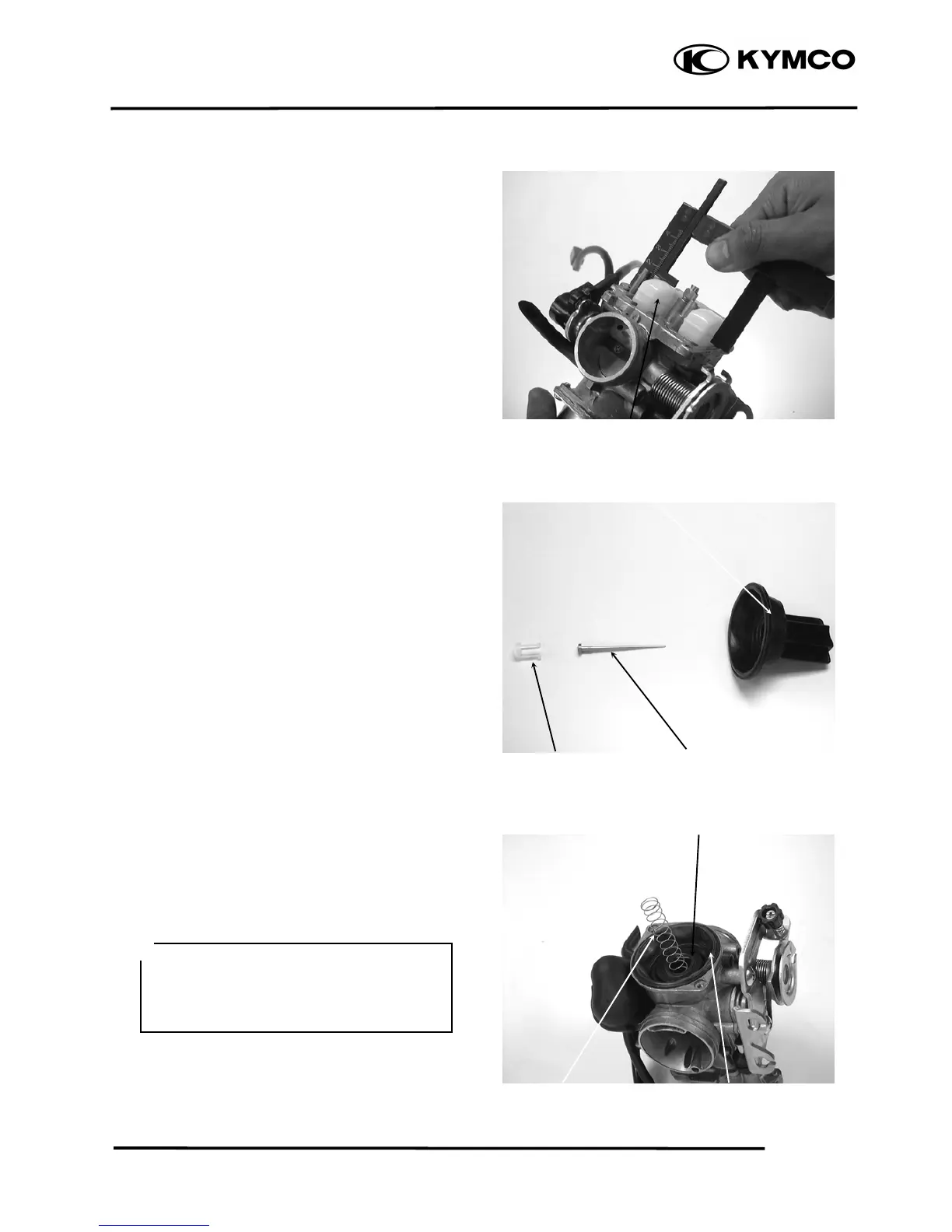

First install the jet needle and spring into the

vacuum chamber and then install the needle

holder.

Install the vacuum piston into the carburetor

body.

Install the spring.

Install the vacuum chamber cover and

tighten it with the two screws.

Floa

• Be careful not to let the diaphragm

slip.

• If the diaphragm cannot be positioned

correctly because of expansion, dry the

Loading...

Loading...