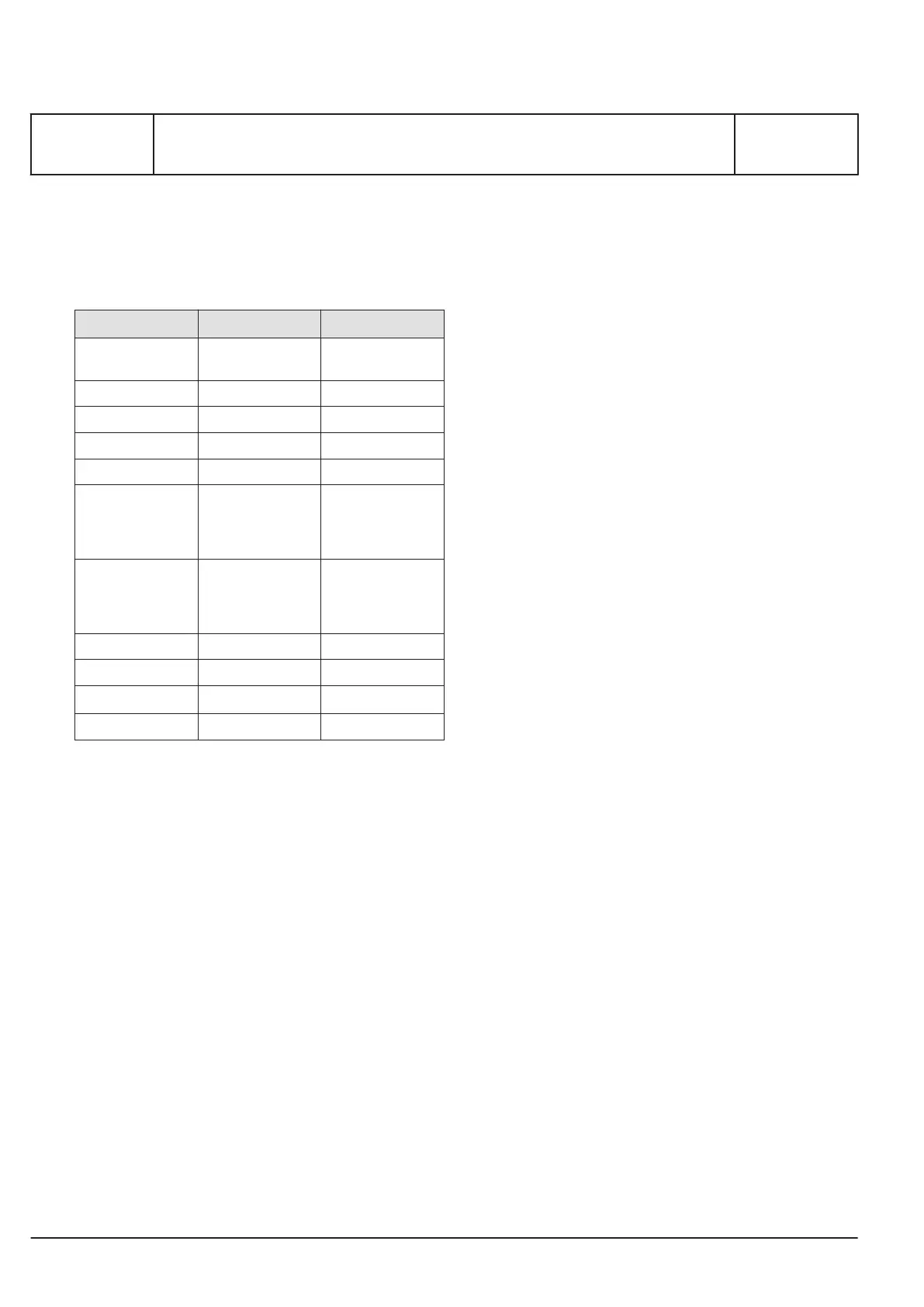

Quality guidelines for circulating and

additive water

Circulating water Additive water

1)

Apperance Colourless, clear,

no sediments

Colourless, clear,

no sediments

pH value

2)

7.5 - 8.5 -

Total salt content < 2,500 ppm < 1,250 ppm

Conductivity < 3,000 µS/cm -

Calcium > 20 ppm > 10 ppm

Carbonate hard-

ness without hard-

ness stabilation

< 4 ûdH

< 71 ppm

CaCO

3

< 2 ûdH

< 35 ppm

CaCO

3

Carbonate hard-

ness with hard-

ness stabilation

< 20 ûdH

< 356 ppm

CaCO

3

< 10 ûdH

< 178 ppm

CaCO

3

Chloride < 200 ppm < 100 ppm

Sulphate < 300 ppm < 150 ppm

KMnO

4

< 100 g/m

3

-

Germ number < 10,000 /ml -

Table 1: Quality guidelines for circulating and additive water

1)

Minimum requirements in the case of contration

factor 2. At a higher concentration the values are

accordingly lower.

2)

When using chemical additives, the pH values

may be located outside the specified range.

Monitoring of the water quality

pH Value, water hardness and conductivity of the

circulating water should, at least, be measured

every 2 weeks. Based on the conductivity, it can be

checked whether the prescribed concentration fac-

tor is kept. Regular checks must include the values

stated in

Table 1

.

Utilisation of biocides

Intensive venting of the water in the cooling tower

and insulation will, above all, during the warm sea-

son, cause algeas and microorganisms, which clog

the cooling system, support corrosion and clearly

reduce the cooling efficiency.

Growth by algeas, shells and bacteria colonies

must, therefore, be eliminated by vaccination with

chlorine or effective biocides.

The selection and application of biocides depends

on the occurring microorganisms. Close coopera-

tion with the manufacturer, resp. supplier, would be

recommendable as they dispose of suitable test

processes for micro organism detection as well as

the necessary experience.

Environmental protection, safety

The locally applicable environmental requirements

are, in cooling tower operation, to be taken into

consideration for the discharge of blow-down water

and disposal of the substances (hardness stabilis-

ers, biocides, corrosion inhibitors, dispersants) used

for cooling water treatment.

When using chemical additives, the safety regula-

tions of the manufactures must, by all means, be

observed.

MAN Diesel & Turbo

B 13 00 0

Quality of raw-water in cooling tower operation

(additive and circulating water)

1699250-5.0

Page 2 (2)

L28/32S, L27/38S, L23/30S, L21/31S, L16/24S, V28/32S, L16/24, L21/31,

L23/30H, L27/38, L28/32H

2008.10.27

Loading...

Loading...