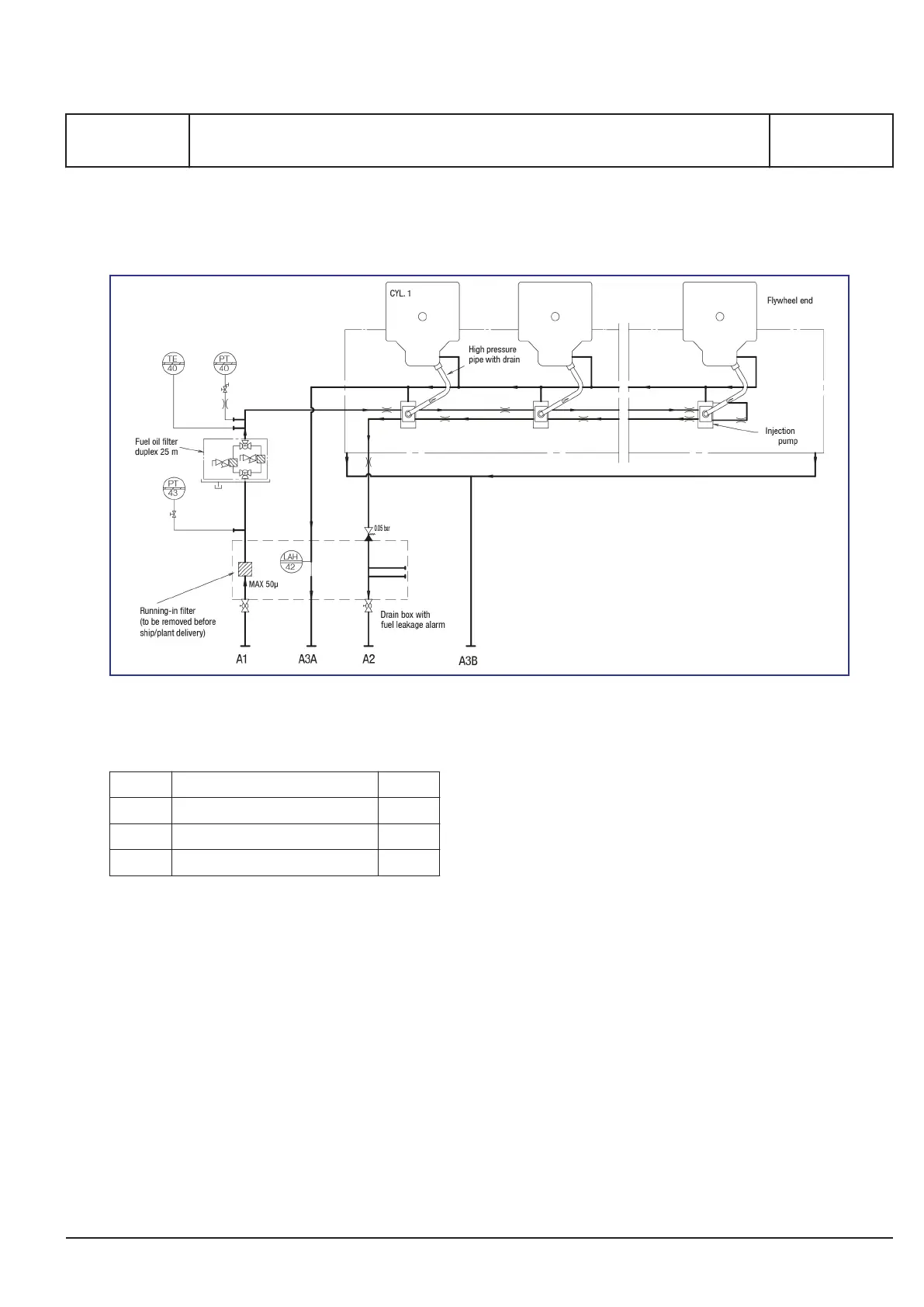

Internal fuel oil system

Figure 1: Diagram for fuel oil system (for guidance only, please see plant specific engine diagram)

Pipe description

A1 Fuel oil inlet DN 25

A2 Fuel oil outlet DN 25

A3A Clean leak oil to service tank DN 15

A3B Waste oil outlet to sludge tank DN 15

Table 1: Flange connections are standard according to DIN 2501

General

The internal built-on fuel oil system as shown in fig.

1 consists of the following parts:

▪ the running-in filter

▪ the high-pressure injection equipment

▪ the waste oil system

Running-in filter

The running-in filter has a fineness of 50 microns

(sphere passing mesh) and is placed in the fuel inlet

pipe. Its function is to remove impurities in the fuel

pipe between safety filter and the engine in the run-

ning-in period.

Note: The filter must be removed before ship deliv-

ery or before handling over to the customer.

It is adviced to install the filter every time the extern

fuel pipe system has been dismantled, but it is

important to remove the filter again when the extern

fuel oil system is considered to be clean for any

impurities.

Fuel oil filter duplex (Safety filter)

GenSets with conventional fuel injection system or

common rail fuel systems are equipped with a fuel

oil filter duplex, with a fineness of max. 25 microns

(sphere passing mesh) The fuel oil filter duplex is

with star-pleated filter elements and allows change-

over during operation without pressure-loss. The fil-

ter is compact and easy to maintain, requiring only

manual cleaning when maximum allowable pressure

drop is reached. When maximum pressure drop is

MAN Diesel & Turbo

3700163-4.1

Page 1 (2)

Internal fuel oil system

B 11 00 0

L27/38S, L27/38

2016.02.05 - Drain split

Loading...

Loading...