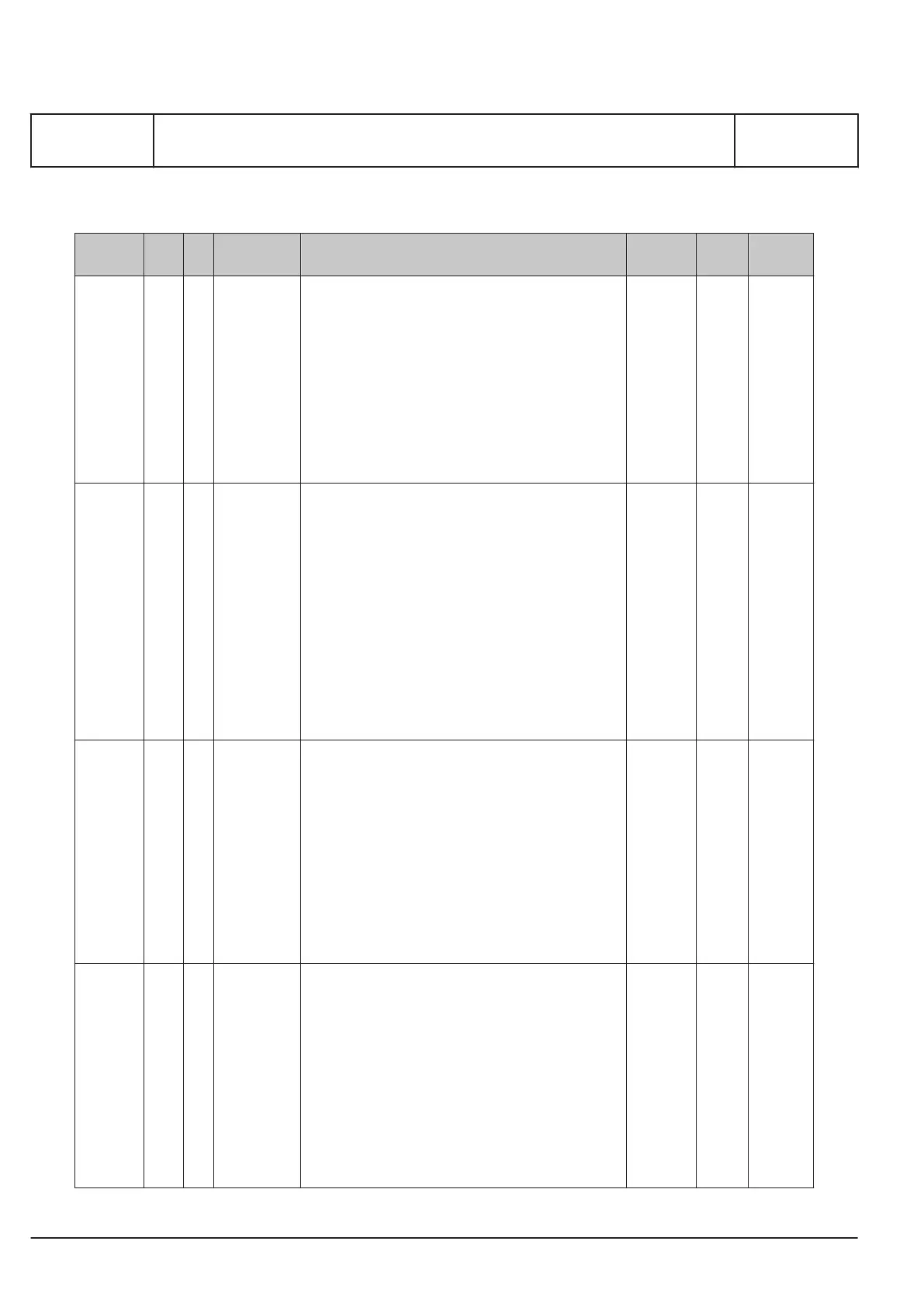

Adress Hex Bit Meas.

Point

Description Unit Origin Signal

range

MW 32

MW 33

MW 34

MW 35

MW 36

MW 37

MW 38

MW 39

MW 40

MW 41

MW 42

MW 43

20

21

22

23

24

25

26

27

28

29

2A

2B

TE12

TE01

TE21

TE40

TE31

TE98-1

TE98-2

TE98-3

TE38

TE10

TE27-1

TE27-2

HT cooling water temperature engine outlet

LT cooling water temperature air cooler inlet

Lube oil temperature filter inlet

Fuel oil temperature engine inlet

Charge air temperature cooler outlet

Alternator windwing temperature L1

Alternator windwing temperature L2

Alternator windwing temperature L3

Ambient air temperature

HT cooling water temperature engine inlet

Alternator front bearing temperature

Alternator rear bearing temperature

CMS

CMS

CMS

CMS

CMS

CMS

CMS

CMS

CMS

CMS

CMS

CMS

0 - 200

0 - 200

0 - 200

0 - 200

0 - 200

0 - 200

0 - 200

0 - 200

0 - 200

0 - 200

0 - 200

0 - 200

MW 48 30 0

1

2

3

4

5

6

7

8

9

10

11

Sensor fault TE12 :

HT cool water temp. engine outlet

Sensor fault TE01 :

LT cool water temp. air cooler inlet

Sensor fault TE21 : Lube oil temperature filter inlet

Sensor fault TE40 : Fuel oil temperature engine inlet

Sensor fault TE31 : Charge air temp. cooler outlet

Sensor fault TE98-1 : Alternator windwing temp. L1

Sensor fault TE98-2 : Alternator windwing temp. L2

Sensor fault TE98-3 : Alternator windwing temp. L3

Sensor fault TE38 : Ambient air temperature

Sensor fault TE10 :

HT cool. water temp. engine inlet

Sensor fault TE27-1 : Alternator front bearing temp.

Sensor fault TE27-2 : Alternator rear bearing temp.

CMS

CMS

CMS

CMS

CMS

CMS

CMS

CMS

CMS

CMS

CMS

CMS

binary

binary

binary

binary

binary

binary

binary

binary

binary

binary

binary

binary

MW 64

MW 65

MW 66

MW 67

MW 68

MW 69

MW 70

MW 71

MW 72

MW 73

MW 74

MW 75

MW 76

40

41

42

43

44

45

46

47

48

49

4A

4B

4C

PT10

PT01

PT21

PT22

PT23

PT40

PT31

PT70

PT43

ZT59

ZT45

PT38

HT cooling water pressure

LT cooling water pressure

Lube oil pressure filter inlet

Lube oil pressure filter outlet

Lube oil pressure TC

Fuel oil pressure engine inlet

Charge air pressure cooler outlet

Start air pressure

Fuel oil pressure filter inlet

Alternator load

Fuel rack position

Ambient air pressure

Analog speed setpoint

CMS

CMS

CMS

CMS

CMS

CMS

CMS

CMS

CMS

CMS

CMS

CMS

CMS

MW 80 50 0

1

2

3

4

5

6

7

8

9

10

11

12

Sensor fault PT10 : HT cooling water pressure

Sensor fault PT01 : LT cooling water pressure

Sensor fault PT21 : Lube oil pressure filter inlet

Sensor fault PT22 : Lube oil pressure filter outlet

Sensor fault PT23 : Lube oil pressure TC

Sensor fault PT40 : Fuel oil pressure engine inlet

Sensor fault PT31 : Charge air press. cooler outlet

Sensor fault PT70 : Start air pressure

Sensor fault PT43 : Fuel oil pressure filter inlet

Sensor fault ZT59 : Alternator load

Sensor fault ZT45 : Fuel rack position

Sensor fault PT38 : Ambient air pressure

Sensor fault : Analog speed setpoint

CMS

CMS

CMS

CMS

CMS

CMS

CMS

CMS

CMS

CMS

CMS

CMS

CMS

binary

binary

binary

binary

binary

binary

binary

binary

binary

binary

binary

binary

binary

MAN Diesel & Turbo

B 19 00 0

Modbus list

3700054-4.0

Page 2 (5)

L27/38S, L16/24S, L21/31S, L16/24, L21/31, L27/38

2015.11.27