HOISTS MLC300 SERVICE/MAINTENANCE MANUAL

5-50

Published 11-22-17, Control # 257-02

Rope That Has Been Idle a Month or More

Wire rope must be given a complete inspection if it has been

idle for a month or more. The inspection must be performed

by a qualified inspector looking for the damage identified

under both daily and periodic comprehensive inspection.

NOTE: Wire rope may be purchased through Manitowoc

Crane Care Lattice Team.

Distributing Wire Rope Wear

Wire rope wear at the “critical wear points” can be reduced

and the life of the wire rope extended by moving the rope at

regular intervals so that different sections of the rope are

subjected to the wear points. This practice can also help

correct spooling problems and rope vibration.

To move the wire rope, cut off a piece of the rope at the worn

end and refasten. The piece should be long enough to move

the wire rope at least one full drum wrap.

If the wire rope is too short to allow cutting off a piece,

reverse the rope end for end and refasten it.

SHEAVE, ROLLER, AND DRUM INSPECTION

Perform the following inspections weekly:

• Check the drum clutches and the brakes for proper

adjustment.

• Check all sheaves, rollers, and drums for the following

conditions:

- Unusual noises

- Freedom of movement—Must turn freely by hand.

Wire rope may need to be loosened to perform this

inspection.

- Wobble—Must turn true with very little side-to-side

or up-and-down play.

- Signs of rust (indicating that water may have

entered bearing).

- Grease leaks (indicating a faulty seal or water in

grease).

The above problems indicate bearing damage. If found,

the corresponding sheave, roller, or drum should be

disassembled for further inspection. New bearings

should be installed.

For sheaves not equipped with grease fittings, be sure to

pack the new bearings with grease at assembly.

• For steel sheaves, check the depth, width, and contour

of each sheave using a groove gauge (see Figure 5-30

).

Replace the sheaves that have oversized or undersized

grooves.

• Replace any grooved drums that allow one wrap of the

wire rope to contact the next wrap as the rope spools

onto the drum.

• Inspect the sheaves to verify they do not contact another

sheave or structural plate work. There should be uniform

clearance between sheaves in a cluster. Repair or

replace worn or damaged sheaves.

• Remachine or replace steel sheaves, drums, or rollers

that have been corrugated by the wire rope’s print (see

Figure 5-31

).

• Measure the nylon sheaves for excessive tread wear

(see Figure 5-33

). To check for uneven wear, measure

at three places.

Wear must not exceed the limit given. Replace worn or

damaged sheaves.

WARNING

Falling Load Hazard!

Replacement wire rope can break if it does not meet

Manitowoc Cranes specifications given in the following

publications supplied with your crane:

• Wire Rope Specifications Chart located in the

Capacity Chart Manual (for load lines)

• Boom or Jib Assembly drawings located in the

Operator Manual (for boom or luffing hoist)

• Mast Assembly drawing located in the Parts Manual

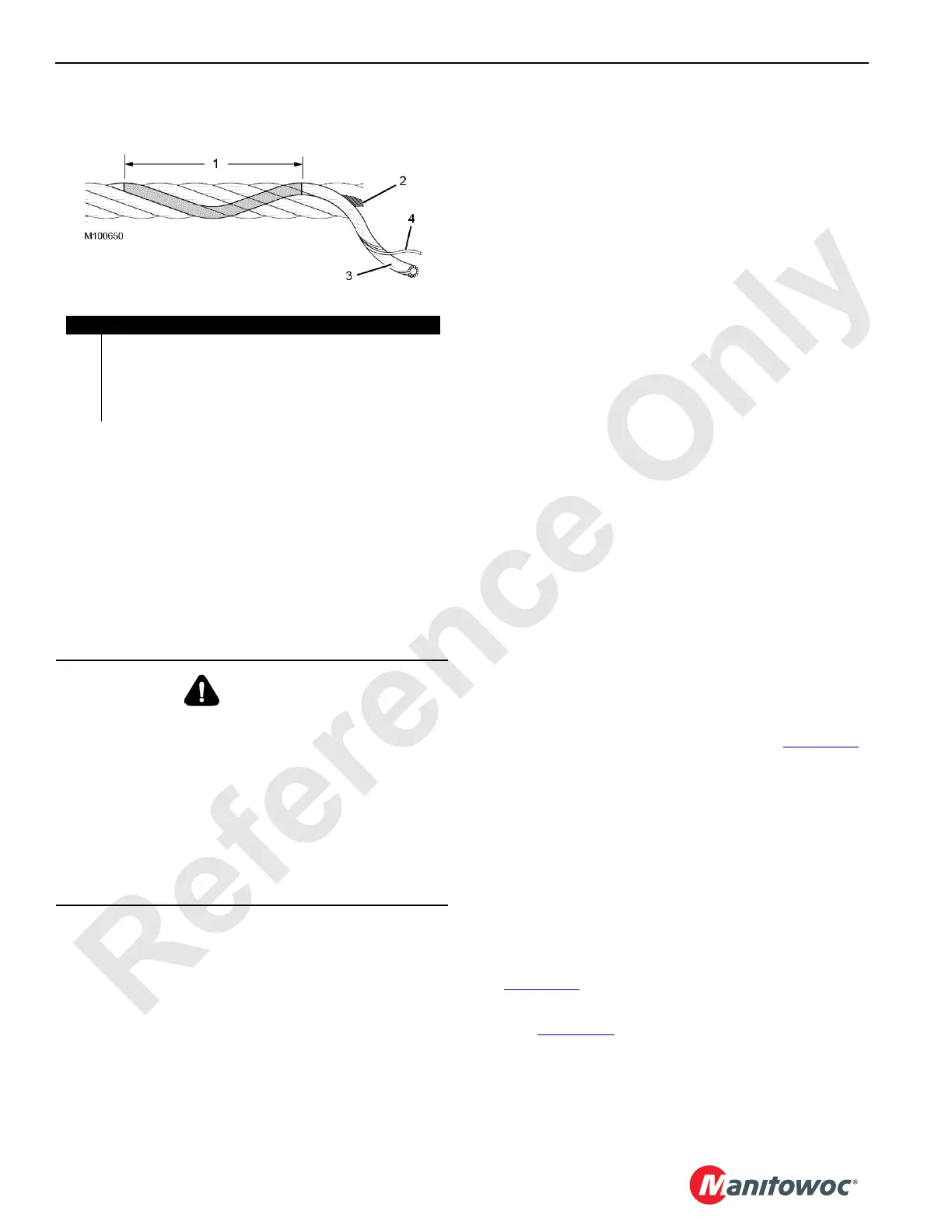

Item Description

1 Lay Length: distance in which one strand makes one

complete revolution around core

2Core

3Strand

4Wire

FIGURE 5-29

Loading...

Loading...