HYDRAULIC SYSTEM MLC300 SERVICE/MAINTENANCE MANUAL

2-28

Published 11-22-17, Control # 257-02

SHOP PROCEDURES

Initial Hydraulic Oil Fill

See Figure 2-15 for the following procedure.

The following procedure is used at the factory to fill the

hydraulic system on a new crane. It is necessary to use this

procedure in the field only if the entire hydraulic system has

been drained.

1. Open the hydraulic tank shut-off valves (12, 13, 14, and

15).

2. Make sure the hydraulic tank quick-drain valves (11) are

closed.

3. At the engine, disengage the engine clutch (see

Figure 2-24

).

4. Stop the engine after disengaging the engine clutch.

5. Open the Schrader valve (5) or the vent valve (6) on the

hydraulic tank to release pressure when filling the

hydraulic tank through the power-fill coupling (3).

6. Fill the hydraulic tank by pumping oil through the power-

fill coupling with an owner-supplied portable pump. Use

new hydraulic oil filtered through a 10-micron filter.

Do not fill the hydraulic tank through the desiccant

breather (7) or the top of Filter 1 (2). The hydraulic

system could be contaminated from unfiltered oil.

7. Fill the hydraulic tank to the Full Cold level on the oil

level sight gauge (4).

8. Fill all motor cases with new hydraulic oil filtered through

a 10-micron filter as follows.

a. Disconnect the fitting from the highest case drain

port of each motor.

b. Fill each motor case to the level of the case drain

port.

c. Reconnect the fittings.

9. Apply 0.20 to 0.34 bar (3 to 5 psi) of owner-supplied air

pressure to the air vent on the hydraulic tank.

The tank breather allows 0.21 bar (3 psi) of pressure to

remain in the tank to force hydraulic oil into the charge

system of the closed circuit lines.

10. Bleed the closed-loop motor cases (Drums 1, 2, and 3)

by cracking open the MA or MB port to release trapped

air.

NOTE: It is extremely important to perform the bleed

procedure described above in the field anytime the

system is drained completely.

11. Check for hydraulic leaks and correct any that are found.

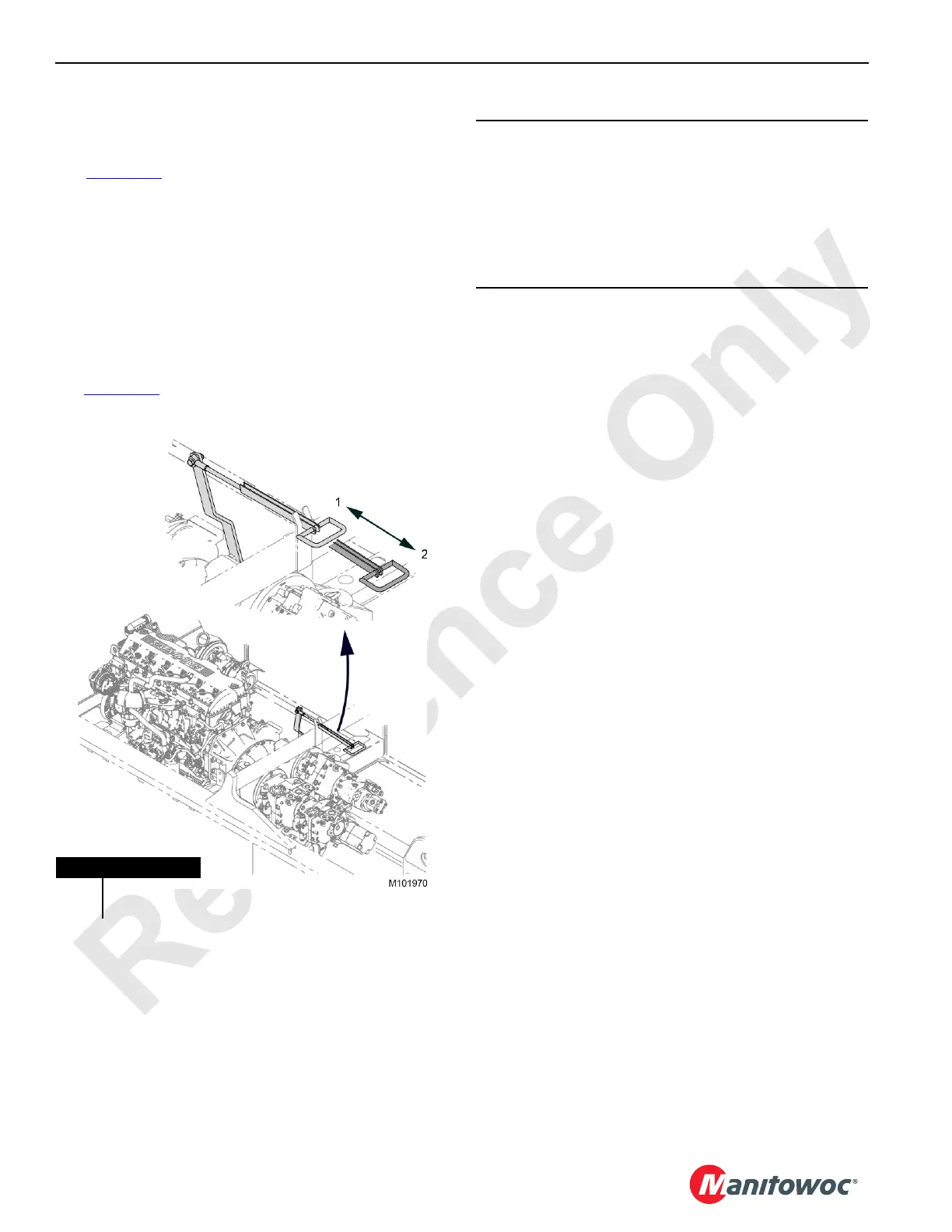

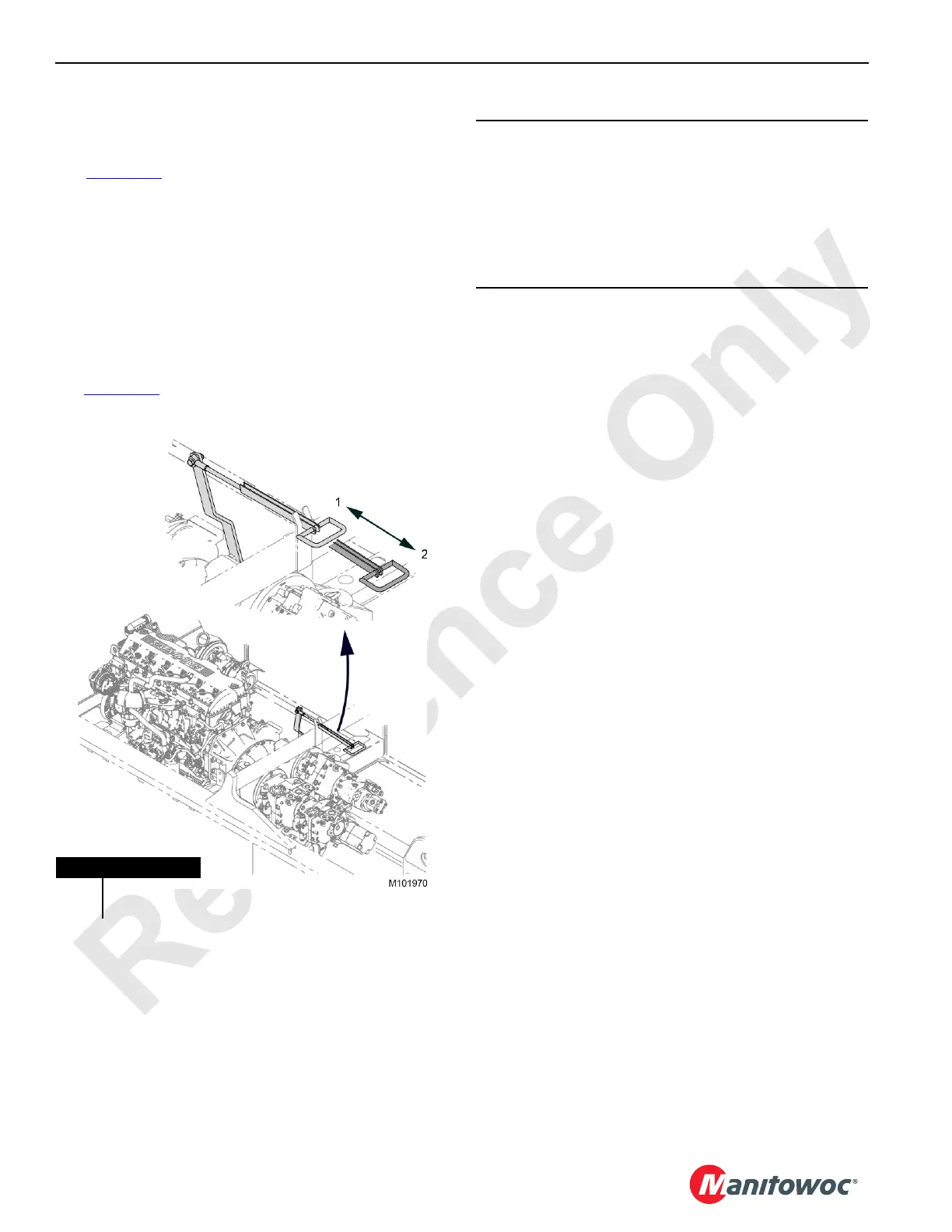

Item Description

1 Engage

2 Disengage

Top of Rotating Bed

FIGURE 2-24

CAUTION

Avoid Engine Clutch Damage!

Observe the following precautions for the engine clutch:

• Decrease the engine speed to idle before engaging

or disengaging the engine clutch.

• Do not run the engine longer than 20 minutes with the

engine clutch disengaged.

Loading...

Loading...