Manitowoc Published 11-22-17, Control # 257-02 7-3

MLC300 SERVICE/MAINTENANCE MANUAL POWER TRAIN

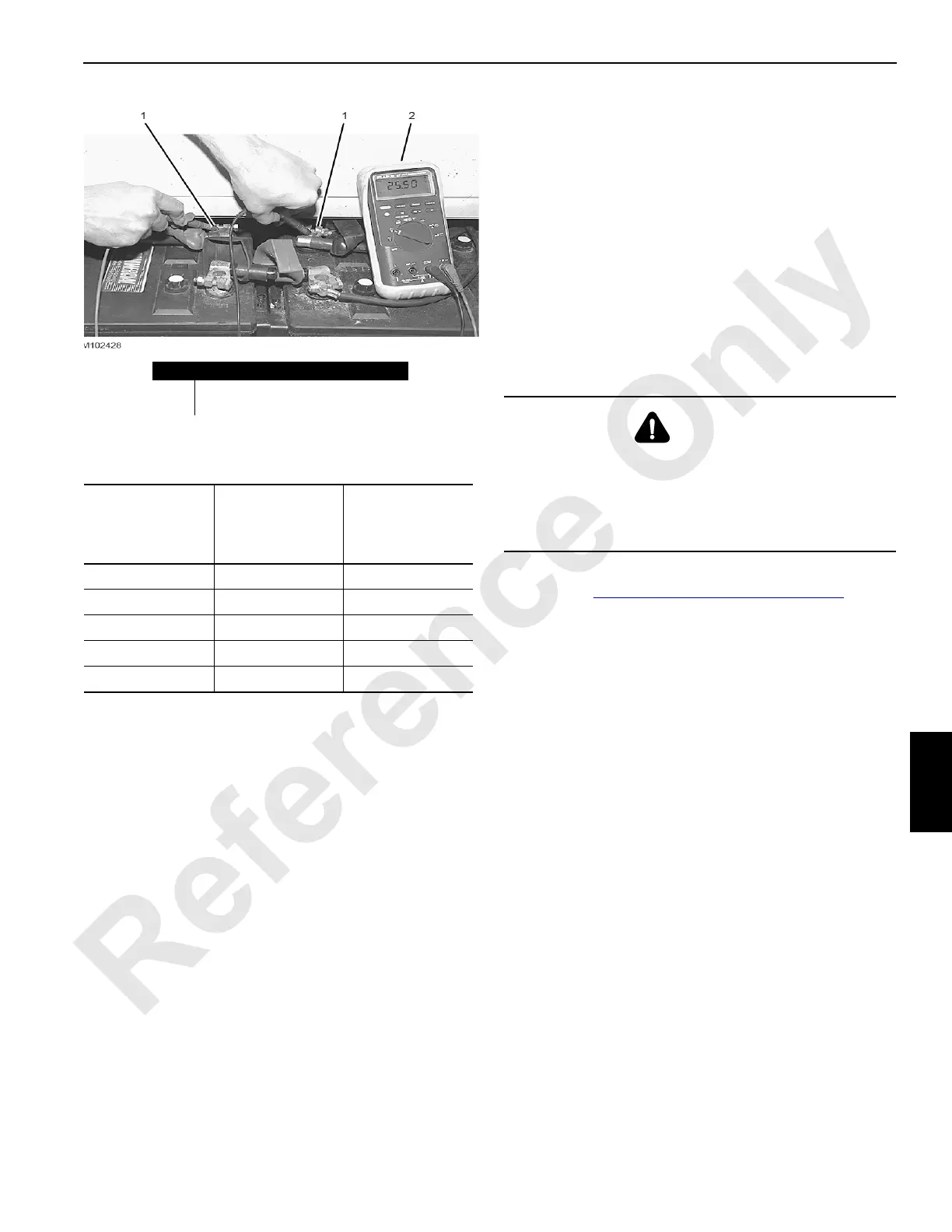

Table 7-2. Open Circuit Voltage

Consult the manual provided with the test meter for detailed

test information.

Troubleshooting—Slow Cranking

If the starter cranks too slowly and the battery is charged and

in good condition, do a voltage-drop test to make sure that

the starter connections are good.

When cranking, a voltage drop of more than 0.6 volts

between the starting motor cable and ground can cause hard

starting regardless of a battery’s condition. The voltage drop

can be caused by a poor contact between the cable terminal

and ground or between the clamp terminal and the battery

post. Also, poor start-switch contacts and frayed, broken, or

corroded cables can be the cause.

Quarterly Battery System Maintenance

• Thoroughly clean the batteries and the holder with a

baking soda/water solution.

• If provided, make sure the drain holes are open in the

holder. If water collects in the holder, drill some drain

holes.

• Clean the posts and terminals. The posts can be lightly

coated with petroleum jelly to prevent corrosion.

• Make sure that the hold-downs are in good condition.

Replace any faulty parts.

• Replace frayed, broken, or corroded cables.

• Replace the batteries if their containers are cracked or

worn to the point that they leak.

• Ensure there is tight contact between the clamp

terminals and battery posts.

• Make sure the hold-downs are tight enough to prevent

battery movement, but not so tight as to cause distortion.

Charging

NOTE: If the crane is equipped with the optional charger,

see Battery Charger (optional) on page 7-4

.

1. Remove the battery or disconnect all the crane wiring

from the battery.

2. Read and follow the charger manufacturer’s

instructions.

NOTE: The battery should be at room temperature when

recharging. Never attempt to recharge a frozen

battery.

3. Clean the top of the battery to help prevent dirt from

entering the cells.

4. Verify the plates are covered with electrolyte. If the level

is low, add distilled water to bring the level just to the top

of the plates. Use a clean funnel. Re-check the

electrolyte level after charging.

• The maximum charge rate in amperes should be no

more than 1/3 of the battery’s reserve capacity

minute rating.

NOTE: The Deka 908D battery originally supplied with the

crane has a reserve capacity rating of 430 minutes.

• Do not exceed 13.8 volts for long periods and 14.4

volts for short periods (8 hours maximum).

• Charge until a 2-hour period results in no increase in

voltage or decrease in current.

State of Charge Specific Gravity

Approximate

Open-Circuit

Voltage

(24 V system)

100% 1.260 25.2

75% 1.230 24.8

50% 1.200 24.4

25% 1.170 24.0

0% 1.110 23.6

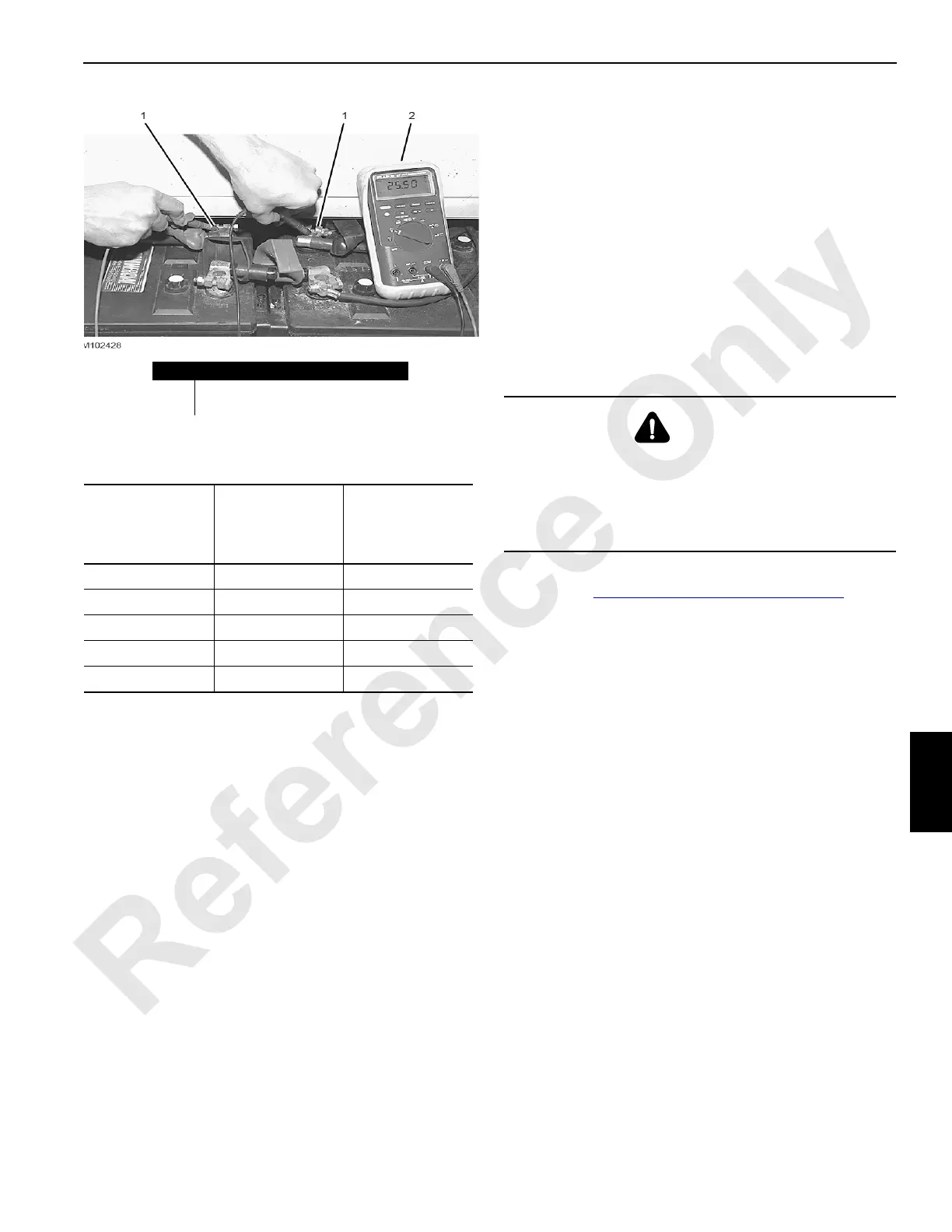

Item Description

1 Test Leads on Battery Terminals

2 Voltmeter

FIGURE 7-2

WARNING

Personal Injury Hazard!

Exposure to battery electrolyte can cause severe burns. If

electrolyte comes in contact with eyes, the area must be

immediately flushed with large amounts of water.

Always wear eye protection when servicing batteries.

Loading...

Loading...