gauge can be inserted at any point, the engine must be re-adjusted until proper

alignment is obtained. This should be performed by an authorized MasterCraft

dealer’s service department.

Step 15: Forallmodels,withtheboatinthewater,cyclethekeyONandthenOFFtwo(2)

orthree(3)times,allowingten(10)secondsbetweenkeycycles,beforecrank-

ingtheengine.Thisallowsthefuelpumptoprimethefuellines;thenstartthe

engine. In the event the engine does not respond, allow a two-minute cool-down

periodforeverythirty(30)secondsofcranking.Whentheengineres,keep

a close watch over the gauge readings and check for leakage and abnormal

noises.Keepspeedslowfortherstfteen(15)minutestoallowtheengineto

reach normal operating temperatures.

Step 16:InProStar197sequippedwithballastbags,whenreconnectingthehook-ups,be

sure to squeeze the prongs to help slide the connector back on. Dish soap or some

similar product will help slide the connects back together. Note that the red ring

goes over the raised ring to ensure a working connection.

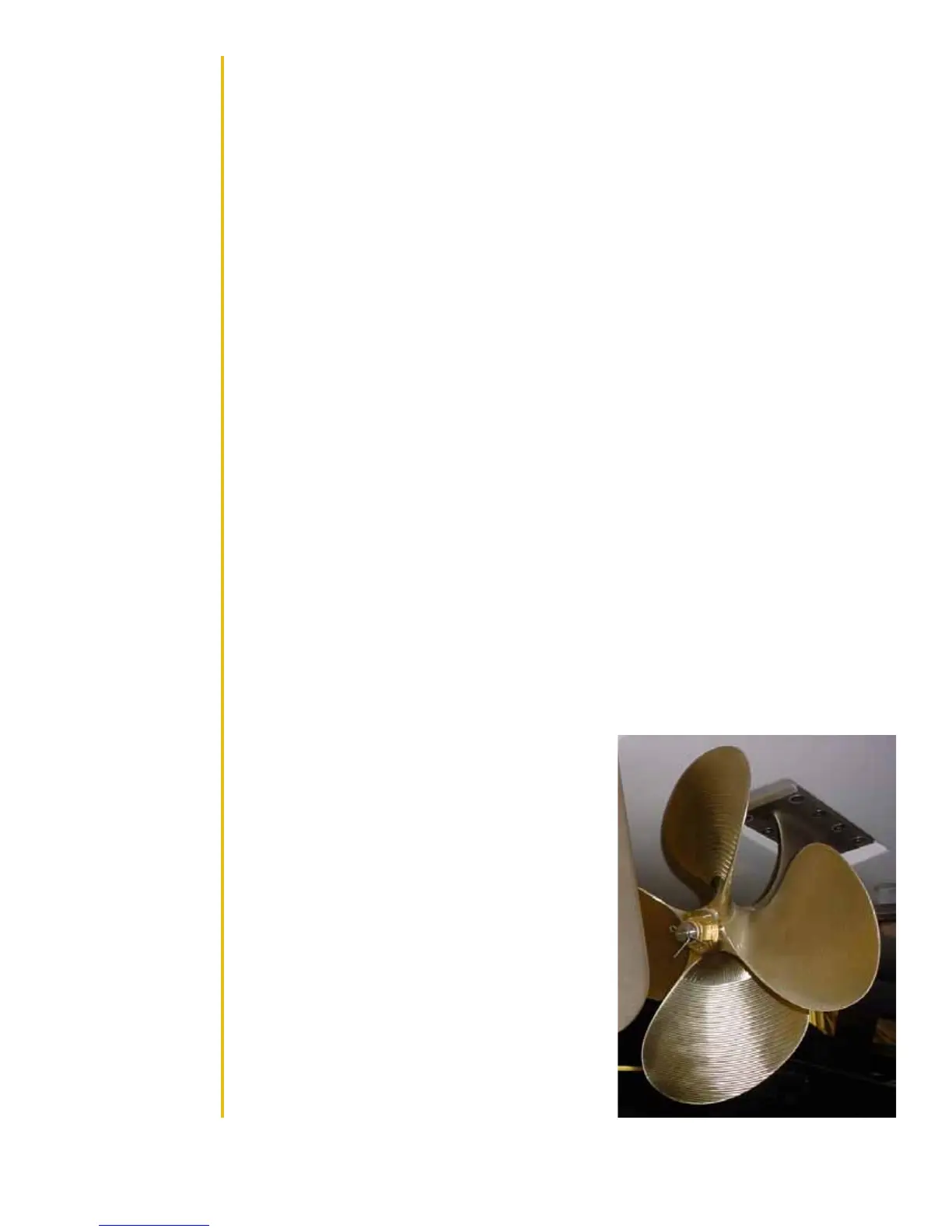

Propeller Maintenance

Propeller damage is caused by striking solid objects. If the propeller is not rotating

at the time it strikes a solid object, the damage is usually confined to just one blade and

may be dicult to see. If the propeller is rotating when it strikes an object, usually the

resulting damage can easily be seen on all blades.

Checking/Repairing Propellers

Step 1: Ensure the engine is OFF and the emergency safety stop switch is disconnect-

ed.

Step 2: Clamp a small rule scale to the shaft strut, parallel to the shaft so that the end

ofthescaleis3/32-inchesfromtheleadingedgeofapropellerblade.

Step 3: Rotatethepropellerslowly.Thereshouldbenomorethan3/32-inchvariance

between the blades. If the propeller is damaged, see an authorized MasterCraft

dealer.

Changing Propellers

Step 1: Ensure the engine is OFF and the engine

safety starting switch is disconnected.

Step 2: Removeanddiscardthecotterpin.

Step 3: Removethepropellernut.

Step 4: Tap the center hub of the propeller with

a rubber mallet to release the propeller.

Inspect the shaft and propeller splines for

damage.

Step 5: Thoroughly clean and apply a light coat of

waterproof marine multi-purpose grease to

the splined area of the shaft and propeller.

Step 6: Align the splines and carefully install the

propeller onto the shaft. DO NOT FORCE

THE PROPELLER INTO PLACE.

Step 7:Installthepropellernutandtorqueto50-ft-

lbs.

Step 8: Install a new cotter pin and bend the ends

around the shaft to lock the propeller on the

shaft.

2013 MasterCraft Owners Manual • Care and Maintenance • Page 5-33

Loading...

Loading...