OM 780-2 Page 59

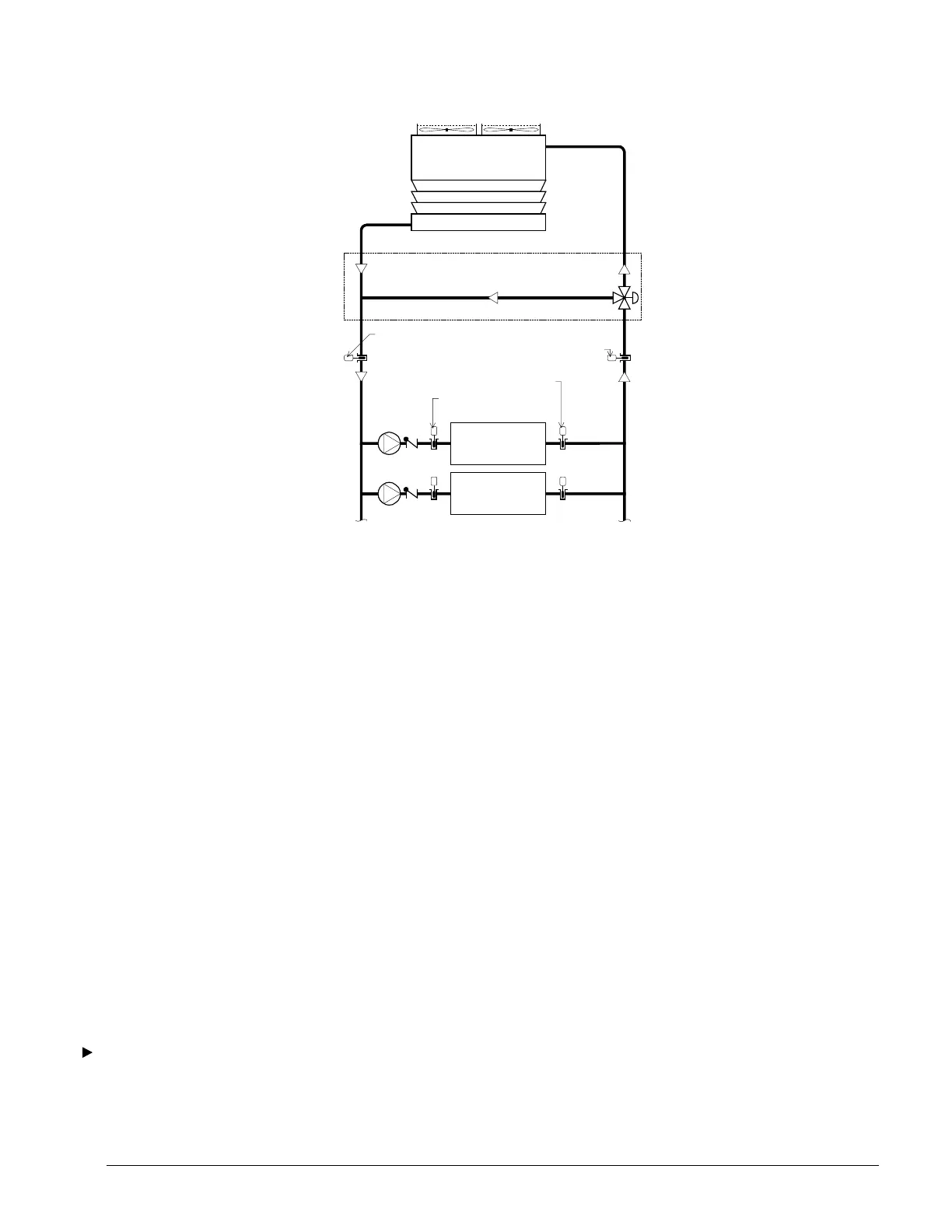

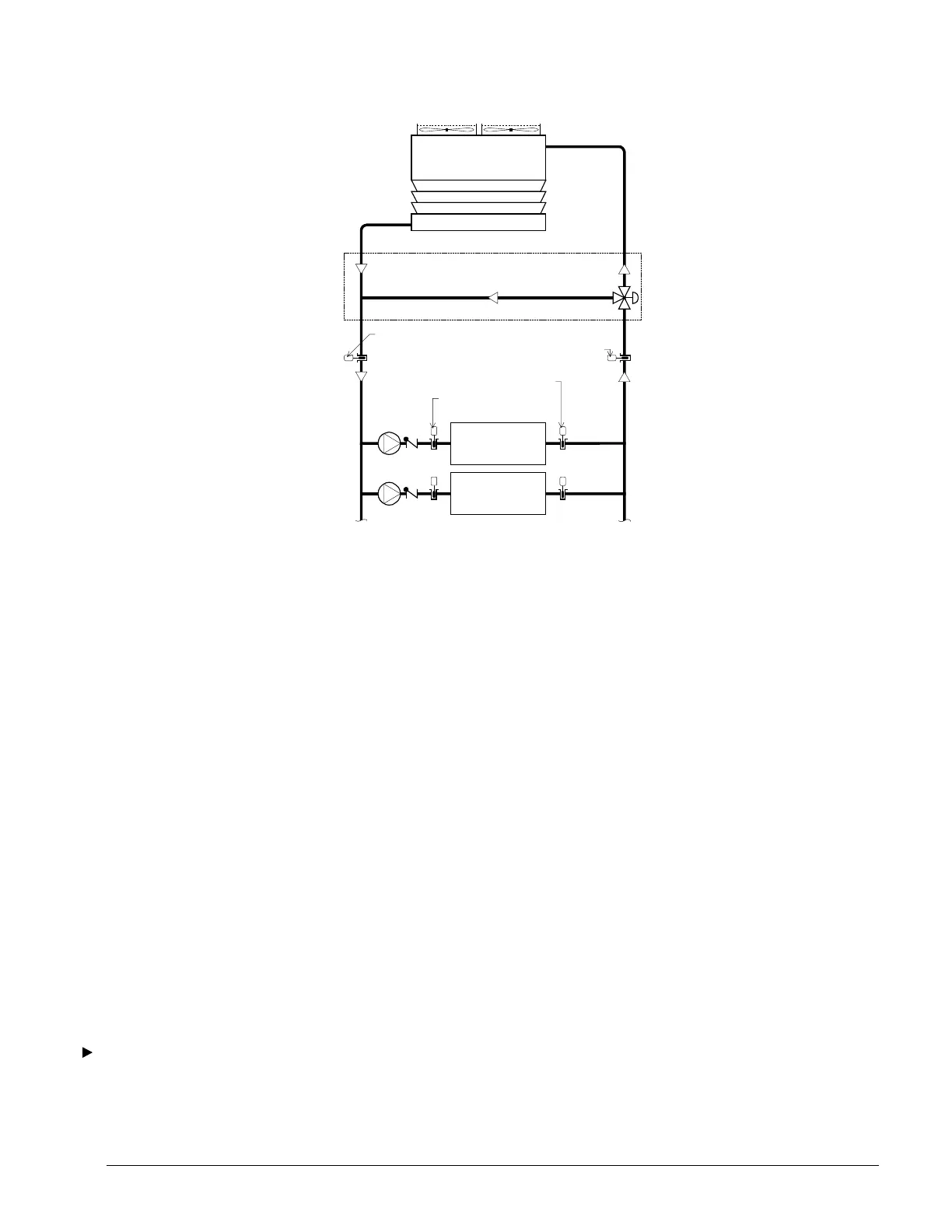

Figure 23. Typical Condenser Water Loop

Chiller #1

Condenser

Common entering condenser water temperature

Common leaving condenser water temperature

Entering condenser

water temperature

Leaving condenser water temperature

Chiller #2

Condenser

Optional cooling tower bypass

a0159

Tower Staging Logic

Cooling tower staging logic depends on whether or not there is a bypass valve in the system, and if there is, it further

depends on how the valve is controlled. There are three possible applications, which are described below:

1. Tower staging only

2. Tower staging with low-limit controlled bypass valve

3. Tower staging with intrastage controlled bypass valve

In all of these applications, the CSM controls up to 16 digital outputs, which can be arranged in up to 12 stages. The

number of outputs does not need to match the number of stages. A separate temperature setpoint is provided for each

cooling tower stage. You can change each of the 12 tower stage setpoints.

Control Temperature

The CSM controls the tower stages and the tower bypass valve (if any) to maintain a desired condenser water temperature.

This temperature is called the Control Temperature, and it can be either the common entering condenser water temperature

or the common leaving condenser water temperature. You can specify which one it is with the Control Temperature Source

variable.

Tower Stage 1 Setpoint Reset

The Stage 1 Setpoint may be reset, in which case all the other setpoints will be adjusted along with stage 1 based on their

original offset from stage 1. Reset is possible in two ways:

• Set by the BAS

• Continually Reset by the CSM to maintain a constant approach temperature differential between the condenser water

supply temperature and the wet bulb temperature

To set up Constant Approach Reset of the cooling tower’s Stage 1 Setpoint

1. Set the Constant Approach Flag = ON

2. Set the Constant Approach Temperature Differential as required

3. Set the Constant Approach Reset – Minimum Setpoint

Loading...

Loading...