Overview

Mercury outboard engines that use the PCM 112 engine control module operate on a speed/density fuel injection strategy. In

this strategy, the propulsion control module (PCM) monitors the engine’s speed and the intake manifold’s air density. Since

the engine ideally maintains a standard, repeatable fuel pressure, the PCM can calculate how long to keep the fuel injectors

open to achieve the desired air/fuel ratio.

This desired ratio is usually the stoichiometric ratio, that ratio of air to fuel that provides the most complete combustion

possible with a minimum of hydrocarbon or nitrous oxides passed through the exhaust. For gasoline without ethanol it is

typically 14.7:1. For gasoline with 10% ethanol, it is in the area of 14.1:1. Because of this variance, we use the term

equivalency ratio or phi, which is the ratio of the air/fuel as reported by the O2 sensor, and the desired ratio targeted by the

PCM.

The PCM 112 adjusts fueling and other engine parameters to achieve the desired equivalency ratio depending on load and

RPM range.

Speed/Density Theory

The engine is basically a mechanical air pump that pumps a specific amount of air at any specific RPM. The actual amount of

air an engine pumps depends upon the density of the air in the intake manifold. This, in turn, depends upon RPM, throttle plate

position, and barometric pressure.

If the air density in the intake manifold is known, the actual amount of air flowing through the engine (the air mass or mass air

flow) could be calculated. This calculated air flow is a repeatable function, meaning that at a specific RPM and a specific

manifold absolute pressure (MAP) reading, the air flow through the engine will always be the same.

The PCM uses a manifold absolute pressure sensor to measure the manifold pressure. It records this information as a

measurement above absolute zero. This is similar to the way a barometer works and is unlike a conventional vacuum gauge,

which measures the manifold pressure below the current atmospheric pressure. The use of the MAP sensor allows the system

to compensate for variations in altitude and weather. A conventional vacuum gauge cannot provide this critical information.

As the PCM measures the engine speed with a crankshaft sensor and the air density with the MAP, it refers to a programmed

lookup fueling table. This lookup table contains correct fuel injector information for every possible engine RPM, demand, and air

density. It then sends signals to the ignition coils and fuel injectors to control combustion.

The PCM does not measure fuel pressure; it assumes that the fuel is supplied to the engine at a specified pressure. As long as

the fuel in the fuel rails is maintained at the specified pressure for that engine, the PCM can order the fuel injectors to open for

a specific length of time to inject the precise amount of fuel into the cylinder at the right time for optimal performance. If the

pressure is out of specification, then the actual amount of fuel injected will be more or less than that calculated by the PCM.

Stoichiometry, Equivalency Ratio, and Emissions Control

An air/fuel mixture that is neither rich nor lean will burn all of the fuel and all of the oxygen. This equilibrium point where the

mixture is neither rich nor lean is called the stoichiometric point. (Stoichiometry is a section of chemistry that involves

measuring the relative quantities of chemicals in chemical reactions.) An air‑to‑fuel ratio that is less than stoichiometric is

considered rich, while an air‑to‑fuel ratio that is greater than stoichiometric is considered lean.

In practice, the actual stoichiometric ratio can change based upon factors such as fuel blend. For a 10% ethanol blend, the ratio

may be 14.1:1, while for a pure gasoline fuel, the air‑to‑fuel ratio is 14.7:1.

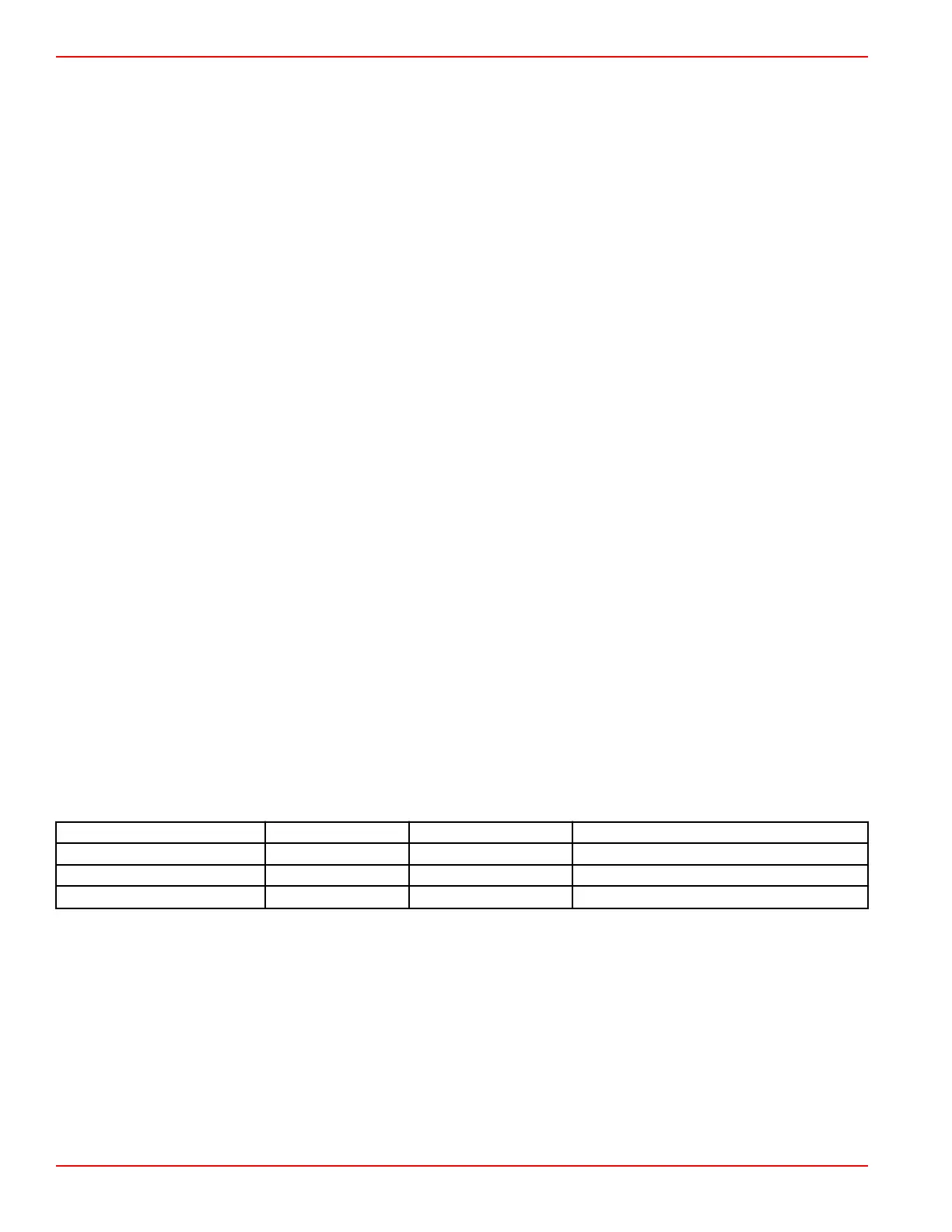

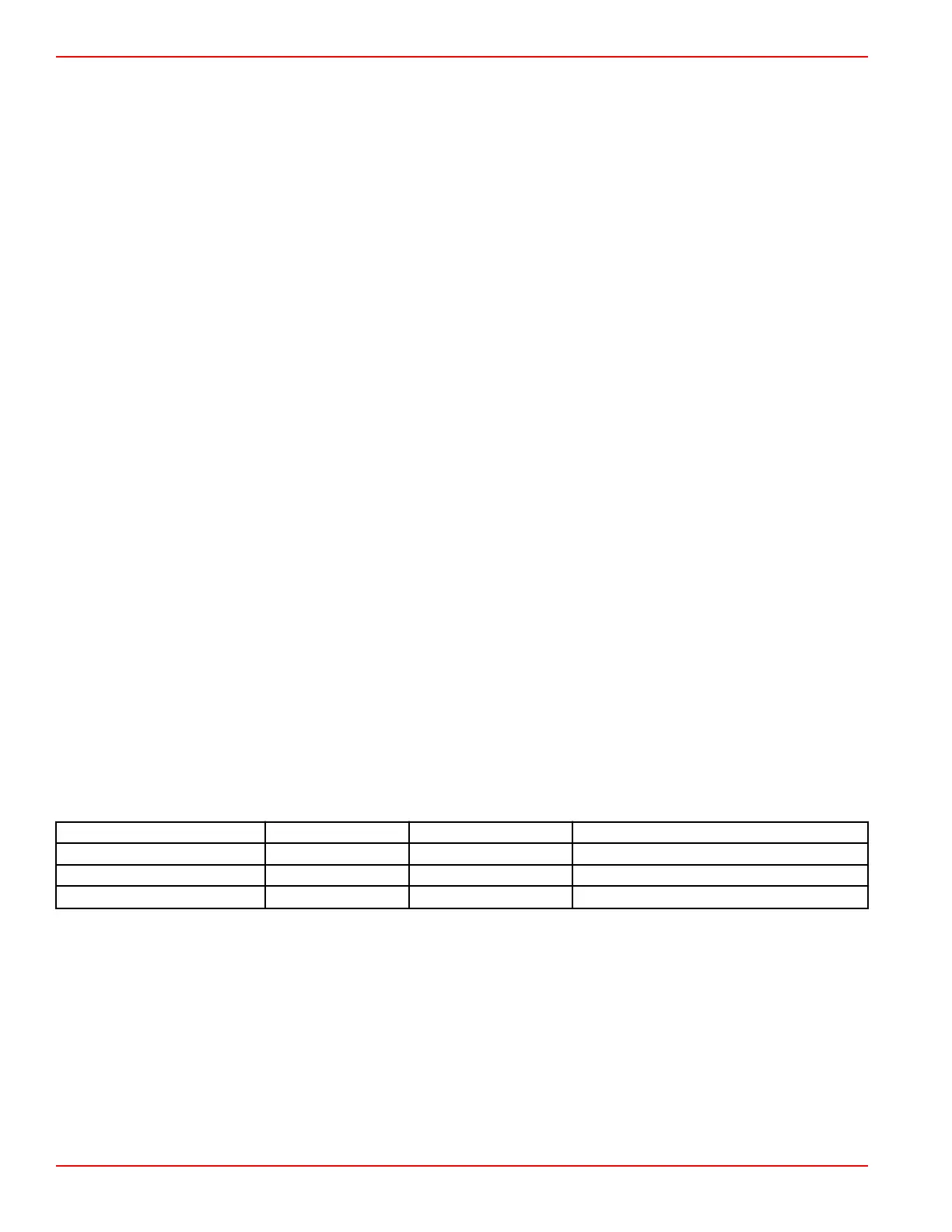

The table below shows some stoichiometric values for different fuels.

Fuel

Rich Stoichiometric Lean

Straight ethanol 8.9:1 and lower 9.0:1 9.1:1 and higher

Straight gasoline 14.6:1 and lower 14.7:1 14.8:1 and higher

E10 (gasoline w/10% ethanol) 14.12:1 and lower 14.13:1

14.14:1 and higher

To allow for these differences, Mercury uses the equivalency ratio. This is defined as the ratio of the ideal air/fuel ratio to the

actual air/fuel ratio: ideal/actual = equivalency ratio. An equivalency ratio of 1.00 means that the combustion is stoichiometric. A

ratio of 1.03 means the blend is 3% rich. A blend of 0.97 means that it is 3% lean.

System Theory

Page 1B-2 © 2018 Mercury Marine 90-8M0146617 eng JULY 2018

Loading...

Loading...