7 Special Control

7.1 Oil Return Operation

In order to prevent compressors from running out of oil, the oil return operation is conducted to recover oil that has flowed

out of the compressor(s) and into the piping system. This operation is performed for all units including units that are in

standby.

When the outdoor unit is running in oil return, the digital display on outdoor main PCB will display “d0”.

Cooling Only/Main Cooling Oil Return Control

Timing of oil return operation:

Calculated oil discharge has reached to specified level. The higher the compressor frequency step is, the more oil

discharge.

Initial cumulative compressor operating time reaches 2 hours.

Cumulative compressor operating time reaches 8 hours.

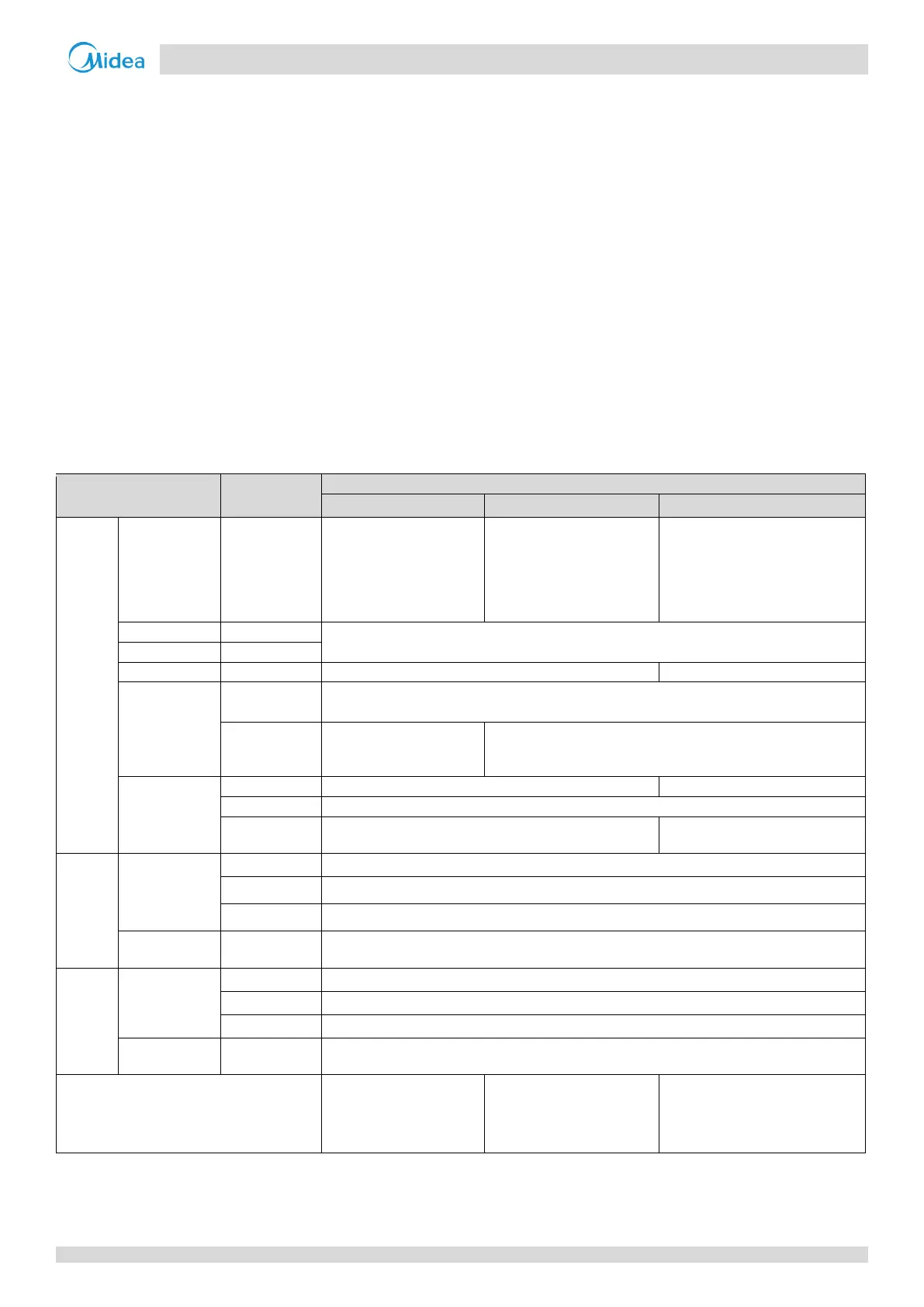

Tables 3-7.1 and Tables 3-7.2 show component control during oil return operation in cooling only/main cooling mode.

Table 3-7.1: Outdoor unit and MS component control during oil return operation in cooling

only/main cooling mode

Cooling oil return control

PI control, the minimum

step is as follows:

8-10HP 28Hz

12-22HP 61Hz

24-34HP 105HZ

36-60HP 165Hz

8-10HP 28Hz

12-22HP 61Hz

24-34HP 105HZ

36-60HP 165Hz

Minimum step(All outdoor unit

compressors are running).

Back to the state before oil return

Electronic

expansion valve

Compressor operation, 2880pls

Compressor not operation, initial 135pls, then adjusted according to the module temperature

Compressor operation, 17pls→ +8pls per 20S based on high

pressure or discharge temperature.

Compressor not operation, 0pls.

Refer to normal operation control

Turn ON/OFF based on the low

pressure and the high pressure etc.

Electronic

expansion valve

Electronic

expansion valve

End if startup time arrives

150S.

End if startup time arrives 6

min or the compressor

discharge volume

≥

Target

value for 4min.

Loading...

Loading...