Pellerin Milnor Corporation 19

Blind Holes

BNUUUN02.T03 0000222507 A.3 B.3 1/2/20 2:14 PM Released

1. Apply the threadlocker down the threads to the bottom of the hole.

2. Apply the threadlocker to the bolt.

3. Tighten the bolt to the value shown in the correct table (Table 6: Threadlocker by the Diame-

ter of the Bolt (see below Note ), page 15 to Table 12: Torque Values for Stainless Steel Fas-

teners 5/16-inch and Smaller, page 17 ).

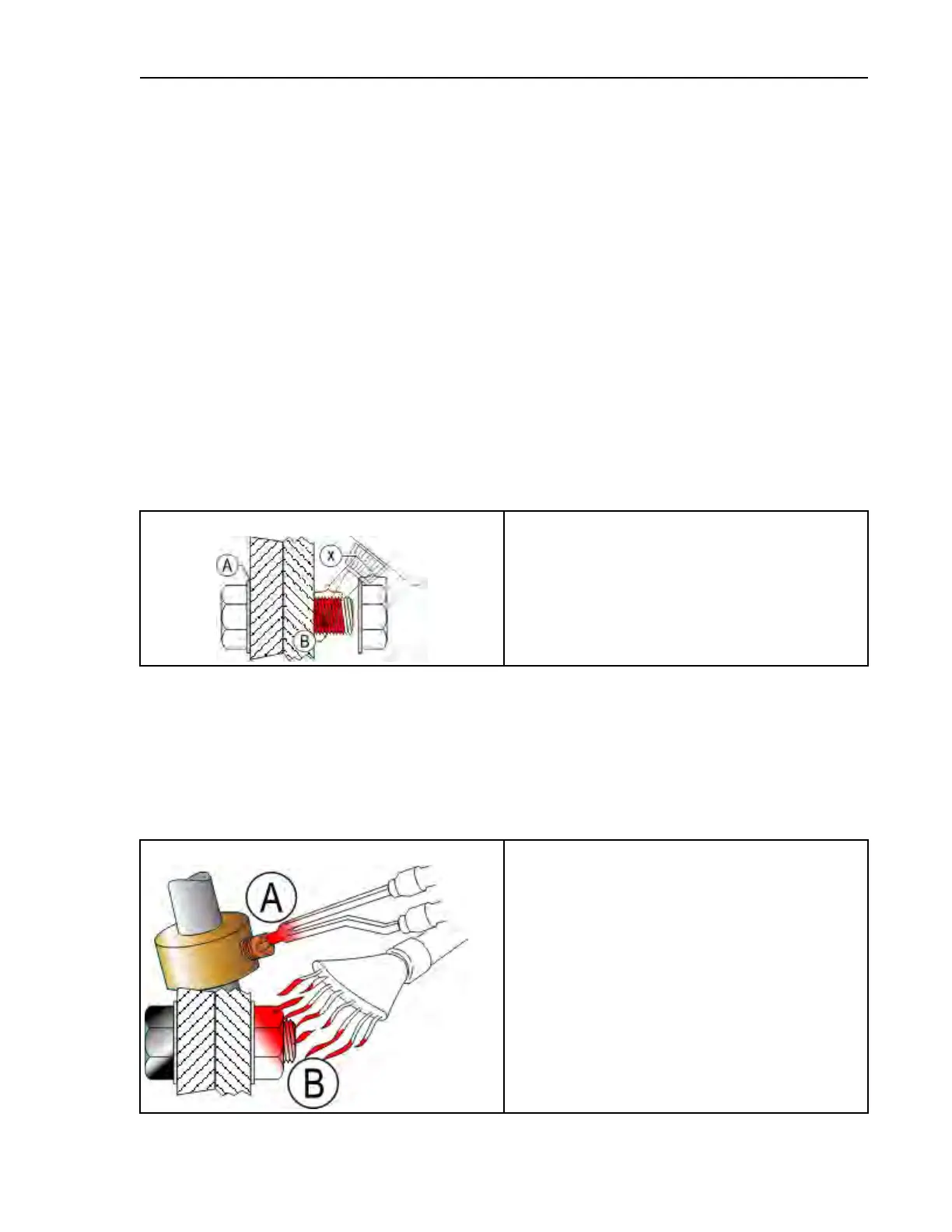

Through Holes

BNUUUN02.T04 0000222506 A.3 B.3 11/26/19 2:51 PM Released

1. Put the bolt through the assembly.

2. Apply the threadlocker only to the bolt thread area that will engage the nut.

3. Tighten the bolt to the value shown in the correct table (Table 6: Threadlocker by the Diame-

ter of the Bolt (see below Note ), page 15 to Table 12: Torque Values for Stainless Steel Fas-

teners 5/16-inch and Smaller, page 17 ).

Figure 3. Apply Threadlocker in a Through Hole

Application

Legend

A...No threadlocker here

B...Apply the threadlocker to this area

X...Nut depth

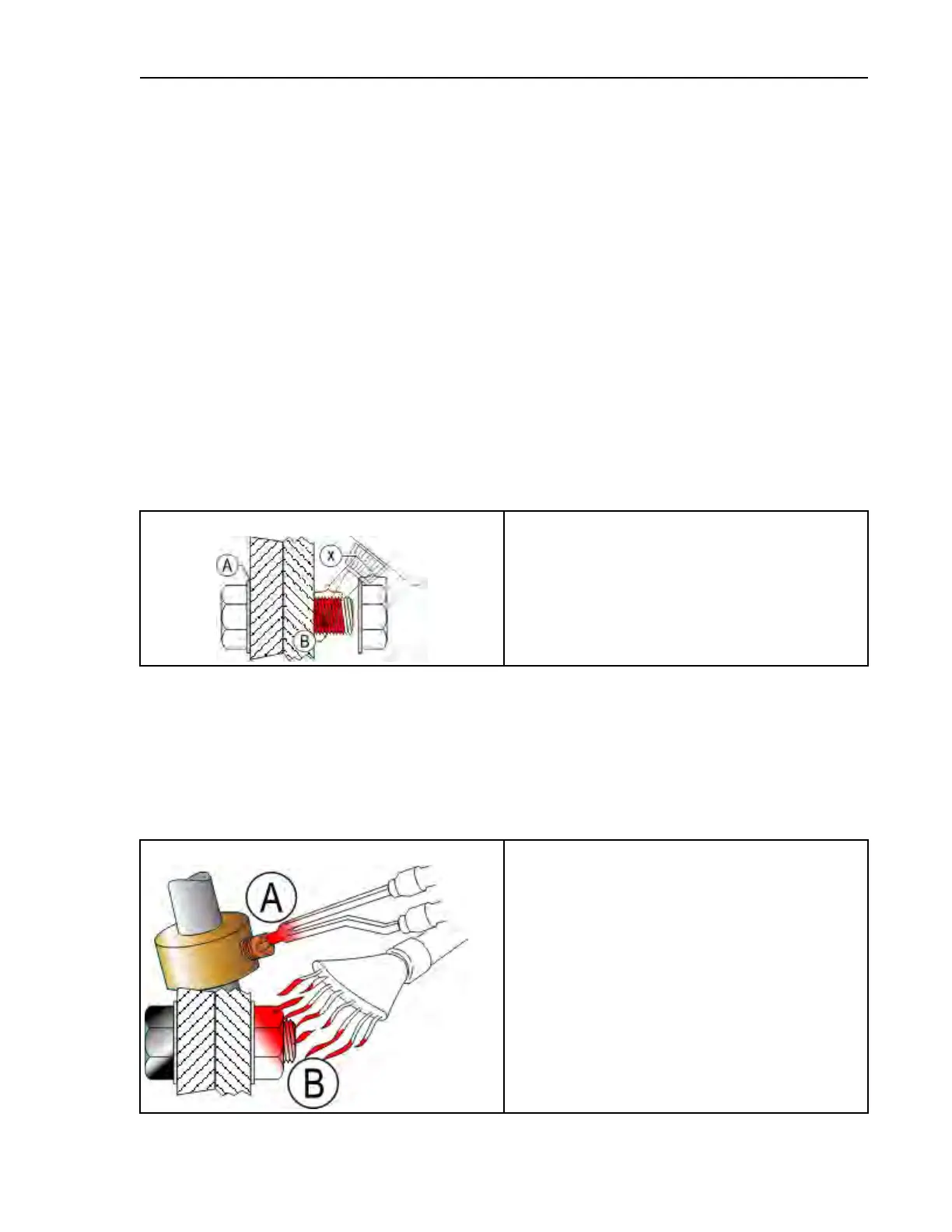

Disassembly

BNUUUN02.C07 0000222444 A.3 B.3 11/26/19 2:59 PM Released

For high-strength threadlocker, apply heat for five minutes. Disassemble with hand tools while

the parts are hot.

For low-strength and moderate-strength threadlocker, disassemble with hand tools.

Figure 4. Use heat for disassembly of fasteners with threadlocker.

Apply Heat to a Small Area

Legend

A...How to apply heat to a small fastener

B...How to apply heat to a large fastener

General Service Information

Loading...

Loading...