Pellerin Milnor Corporation 51

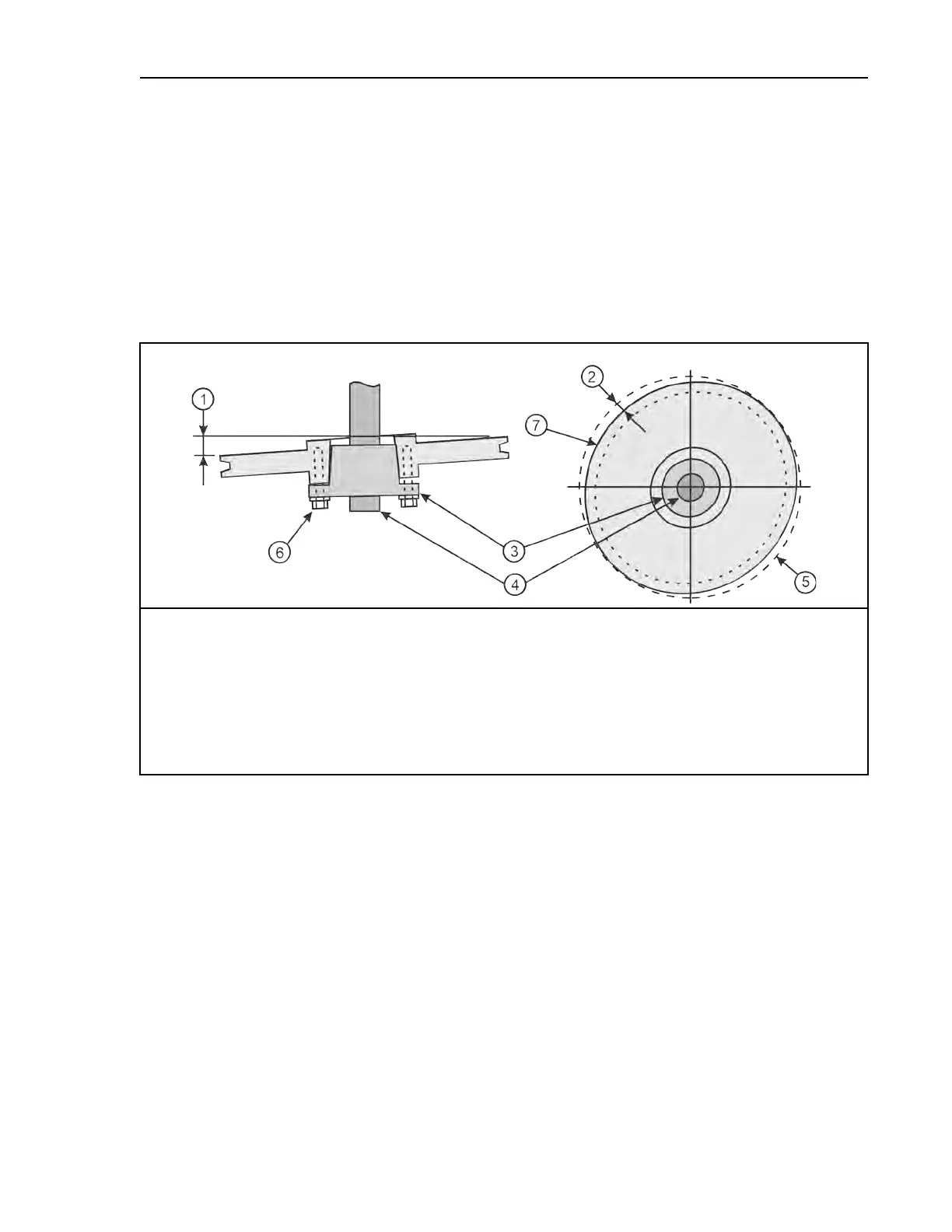

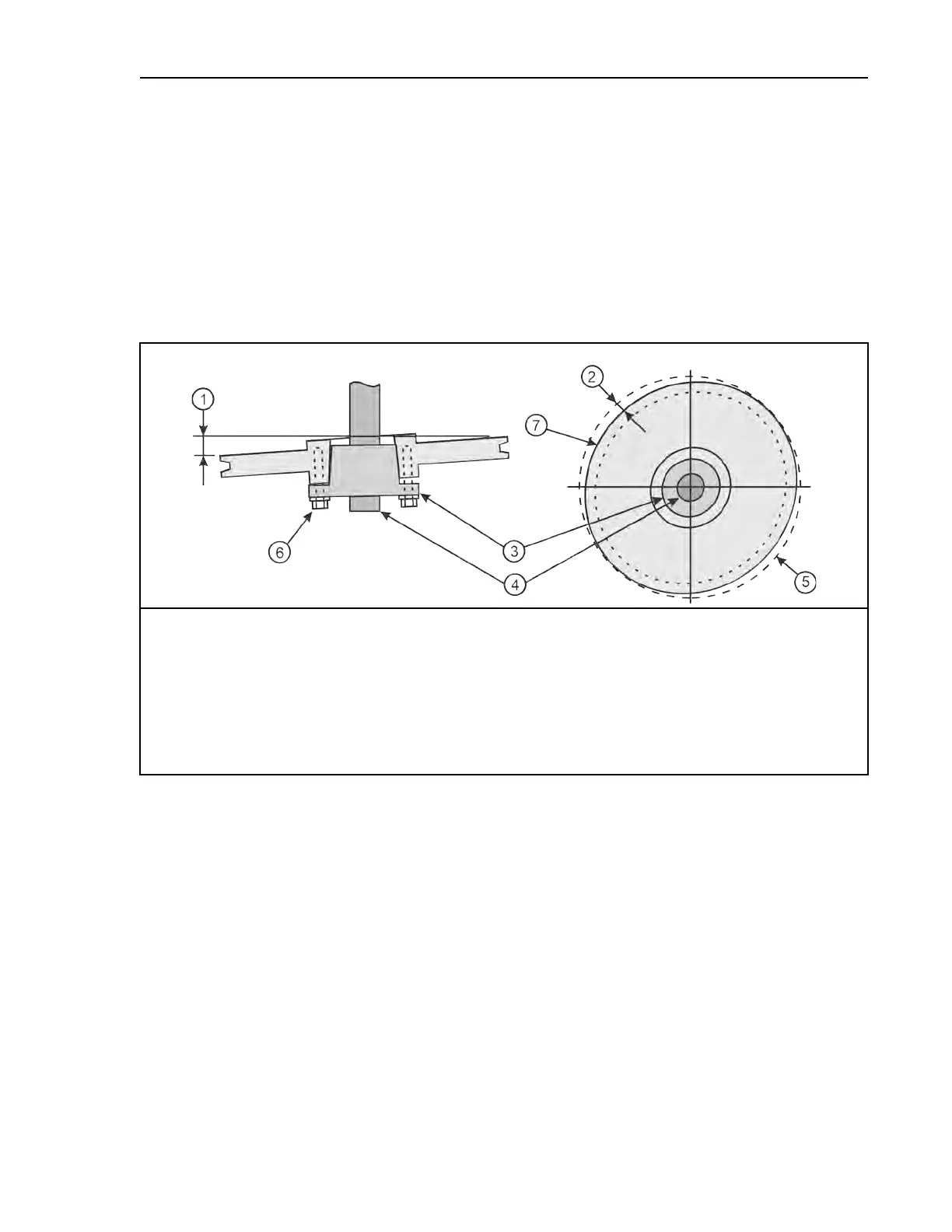

Keep Run-Out in Tolerance

BNUUUM02.C05 0000274606 A.3 A.4 A.2 2/4/20 8:08 AM Released

Axial run-out The difference between the minimum and maximum distance between the face

of a pulley and a plane perpendicular to the pulley shaft (Figure 10 , item 1). Incorrect instal-

lation or damage can cause a pulley to be not at a 90 degree angle to the shaft.

Radial run-out The difference between the minimum and maximum diameter in one turn (Fig-

ure 10 , item 2). If a force causes damage to a pulley, it can bend. It will not have a circular

shape.

Figure 10. Run-out

Views of Axial and Radial Run-out

Legend

1. Axial run-out. This pulley is bent or not perpendicular to the shaft. This condition must not be more than 1 mil

for each inch (0.1 mm for each dm) of the pulley diameter.

2. Radial run-out. This pulley is not circular. This condition must be less than 10 mils (0.25 mm).

3. Bushing

4. Shaft

5. A circle

6. Bushing bolts

7. Sheave

Drive Assemblies

Loading...

Loading...