52

Pellerin Milnor Corporation

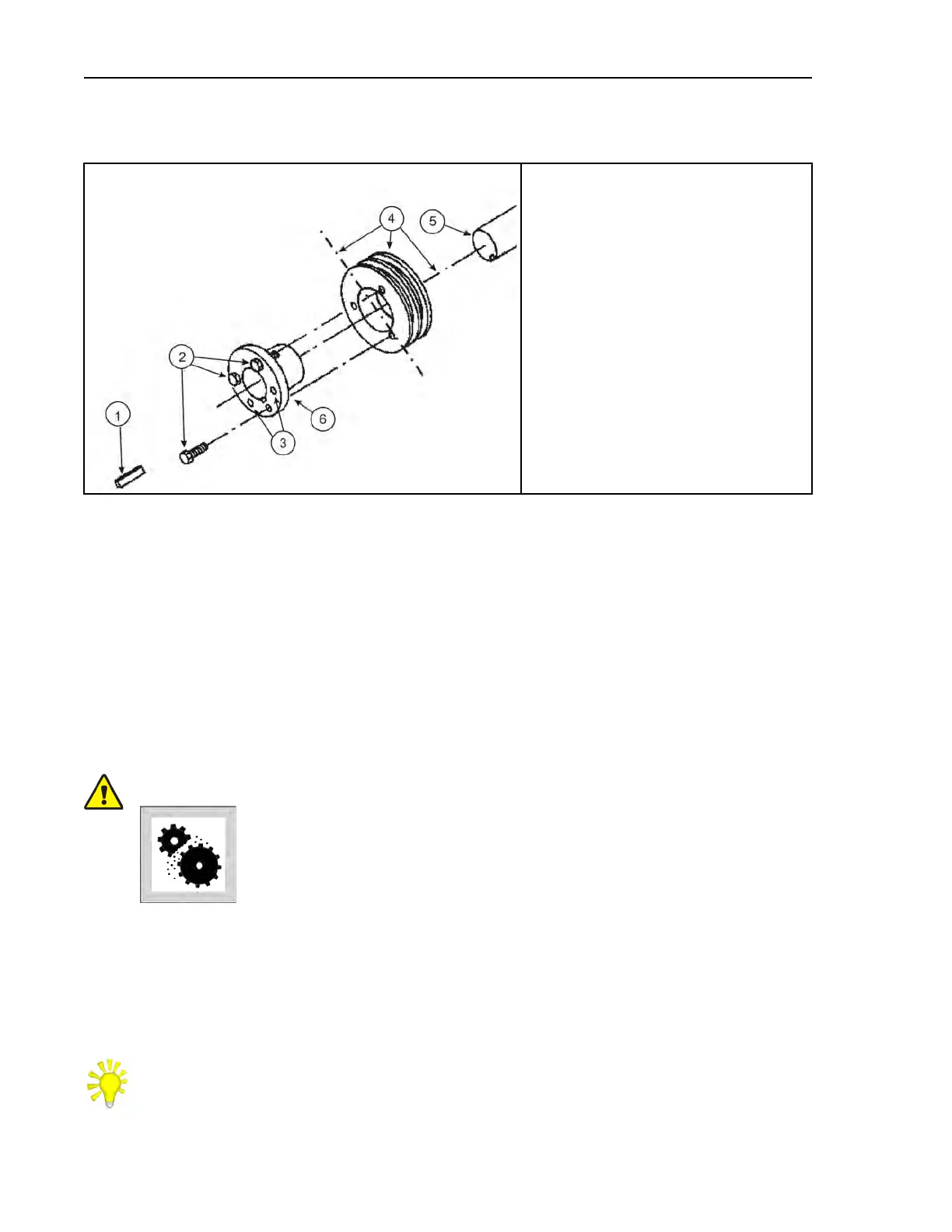

Figure 11. Typical Pulley Assembly

View of Pulley Components

Legend

1. Key

2. Bushing bolts. Tighten bolts in a pattern

that gives the same torque. This will give

minimum axial run-out.

3. Push-off holes

4. Pulley. Measure the radial run-out of the

pulley after you assemble. Make sure that

the center of the pulley is the same as the

center of the shaft.

5. Shaft. Make sure that the shaft is not

bent.

6. Bushing

Belt Requirements

BNUUUM02.C06 0000274605 A.3 A.4 A.2 2/4/20 8:08 AM Released

• Replace damaged belts.

• The pulleys must stay aligned when you adjust the belt tension.

• Do not use belts made from cut belts.

• For a drive with more than one belt:

– Replace all of the belts together.

– Do not mix new and used belts.

– Do not mix belts from more than one manufacturer.

CAUTION: Risk of damage — A screwdriver or metal tool can cause damage to the

belt.

� Do not push the belt on with a tool.

Condition of Belts

BNUUUM02.C07 0000274604 A.3 A.4 A.2 2/4/20 8:08 AM Released

Slippage when the pulley turns more quickly than the belt can move

Slippage occurs if belts are not aligned (see ) or by incorrect tension explained in . Slippage can

cause belts to become too hot. Belts must not have a temperature more than than 140F (60° C).

TIP: The belt storage area must be cool and dry with no sun light.

Drive Assemblies

Loading...

Loading...