[ VIII Disassembly Procedure ]

- 32 -

HWE1804A GB

[2] Disassembly Procedure (PEFY-P72, 96NMHU-E-OA)

1. Control box

Be careful on removing heavy parts.

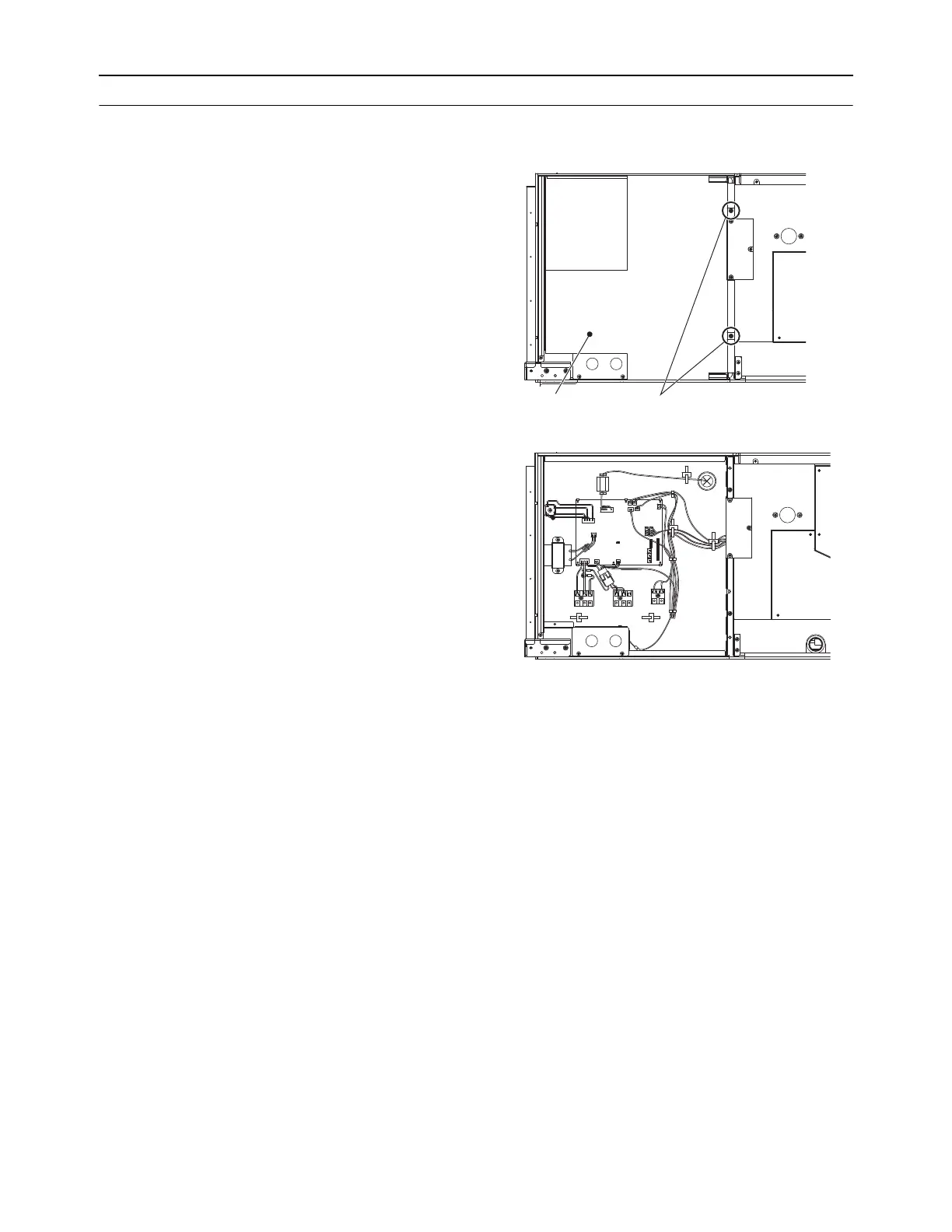

1. Removing the control box cover

(1) Remove the fixing screws (two) of the control box (A), and

remove the cover. (Fig.1)

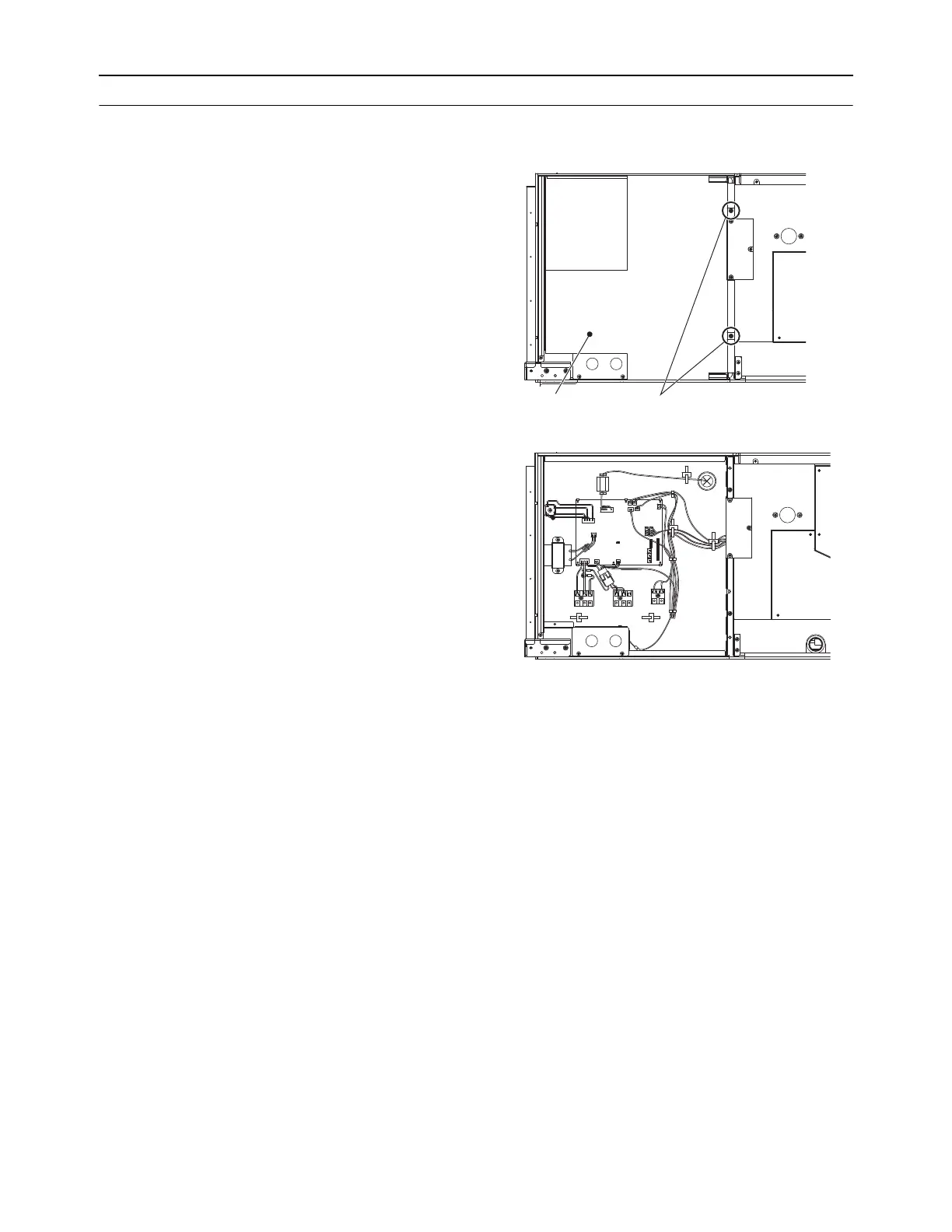

*At this stage, the following servicing is possible. (Fig.2)

1) Operation and check of the switches (listed below) which

are on the control board.

Dip switch SW1 . . . . . . . . . . . . Function change

Dip switch SW2 . . . . . . . . . . . . Capacity code setting

Dip switch SW3 . . . . . . . . . . . . Function change

Dip switch SW4 . . . . . . . . . . . . Model code setting

Dip switch SW21 . . . . . . . . . . . Static pressure setting

Dip switch SW22 . . . . . . . . . . . Function setting

Rotary switches SW11, 12 . . . . Address setting

Rotary switch SW14 . . . . . . . . . Branch port setting

2) Connection check of the lead wires (listed below) which

are connected to the controller board.

Power supply lead wire.

Transmission lead wire x 2

Fan motor lead wire.

LEV lead wire

Inlet air temperature thermistor lead wire

Outlet air temperature thermistor

Liquid piping temperature thermistor lead wire

Gas piping temperature thermistor lead wire

Drain pump lead wire

Float switch lead wire

3) Control board exchange

4) Reactor exchange

5) Thermistor (inlet air, outlet air, liquid piping, gas piping)

exchange

6) Power supply terminal bed exchange

7) Transmission terminal bed exchange x 2

8) Ferrite core exchange

A ferrite core is attached to the wire only when the model

of fan motor is KMUC4E3MW. The model of the motor is

noted in the nameplate on the fan motor casing.

Fig.1

Fig.2

Fixing screws

(A)

Loading...

Loading...