1

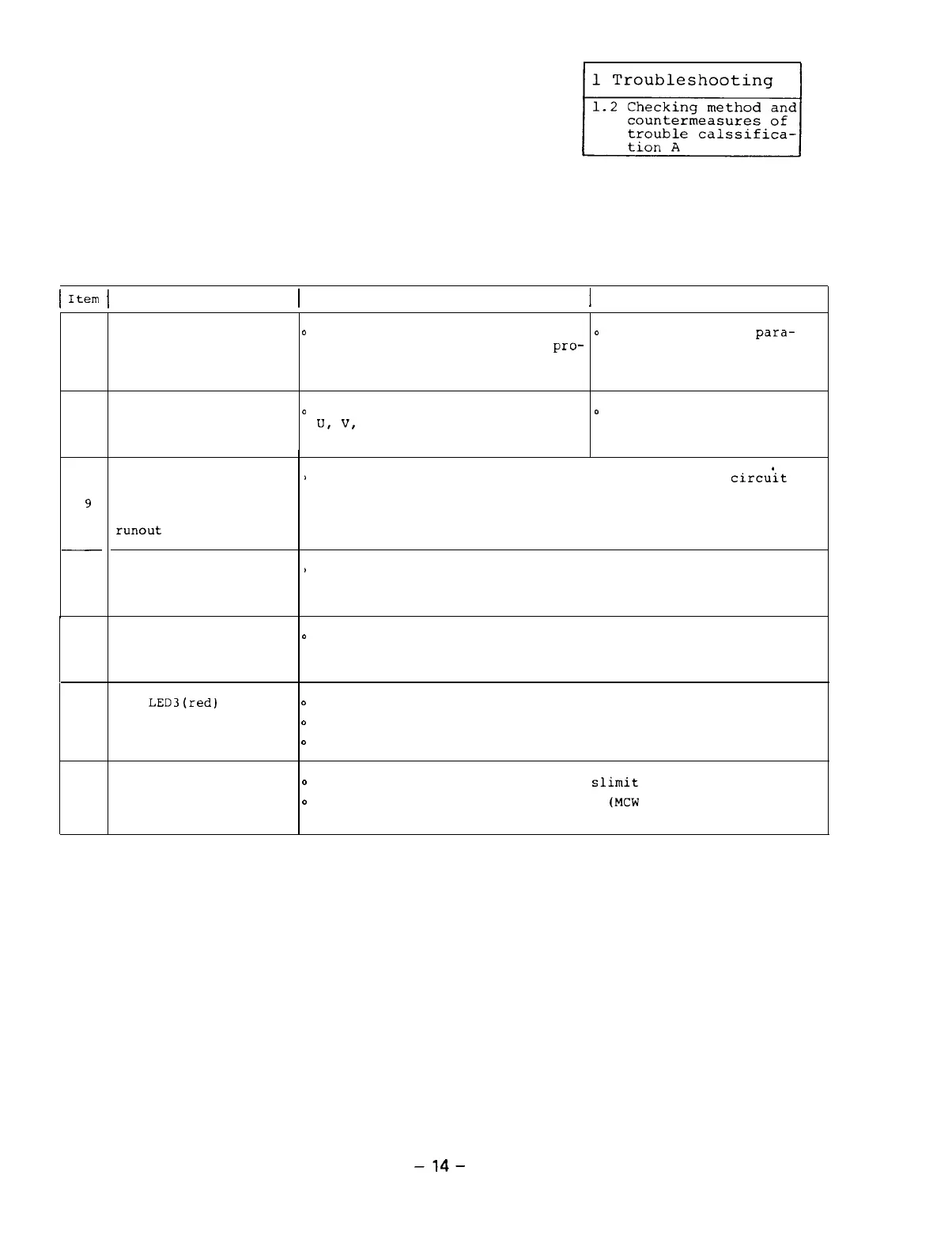

Item

1

Cause

Check

Remedy

The parameters are

0

Check the parameters by comparing

o

Correctly set the

para-

7

incorrectly set.

them with the parameter list

pro-

meters.

vided by the machine manufacturer

(Reference 1.2).

The motor speed cannot

D

Check that the phase sequence of .

o

Correct the phase sequence.

a

be increased (the

D‘

v,

and W between the amplifier

alarm No.

23 occurs).

and motor is correct.

9

10

The motor does not

correctly rotate only

when the orientation

stop takes place (a

runout

occurs).

The alarm disply

of the amplifier

lights.

1

Check and readjust the spindle orientation control

circuyt

by

referencing Chapter 7.

)

Check the cause and take the proper remedy by referencing

Section 1.3.3 which describes the contents of alarms.

An alarm appears on

11

the NC CRT screen.

0

Check the cause and take the proper remedy by referencing

Section 1.1.2 which describes the status display and diag-

nosis.

The

LED3(red)

on the

12

amplifier lights.

0

ROM is defective or incorrectly attached.

0

The power supply (SF-PW Module) is defective.

o

No data is transferred from NC in bus linkage state.

The spindle does not

13

rotate.

o

Check that the spindle parameters

slimit

and smax are not 0.

o

Check that the connection constants

(MCW

and inching) of the

connection parameters are not 0.

-14-