PROGRAM

MI

NG

I

[Sequence instruction description

I

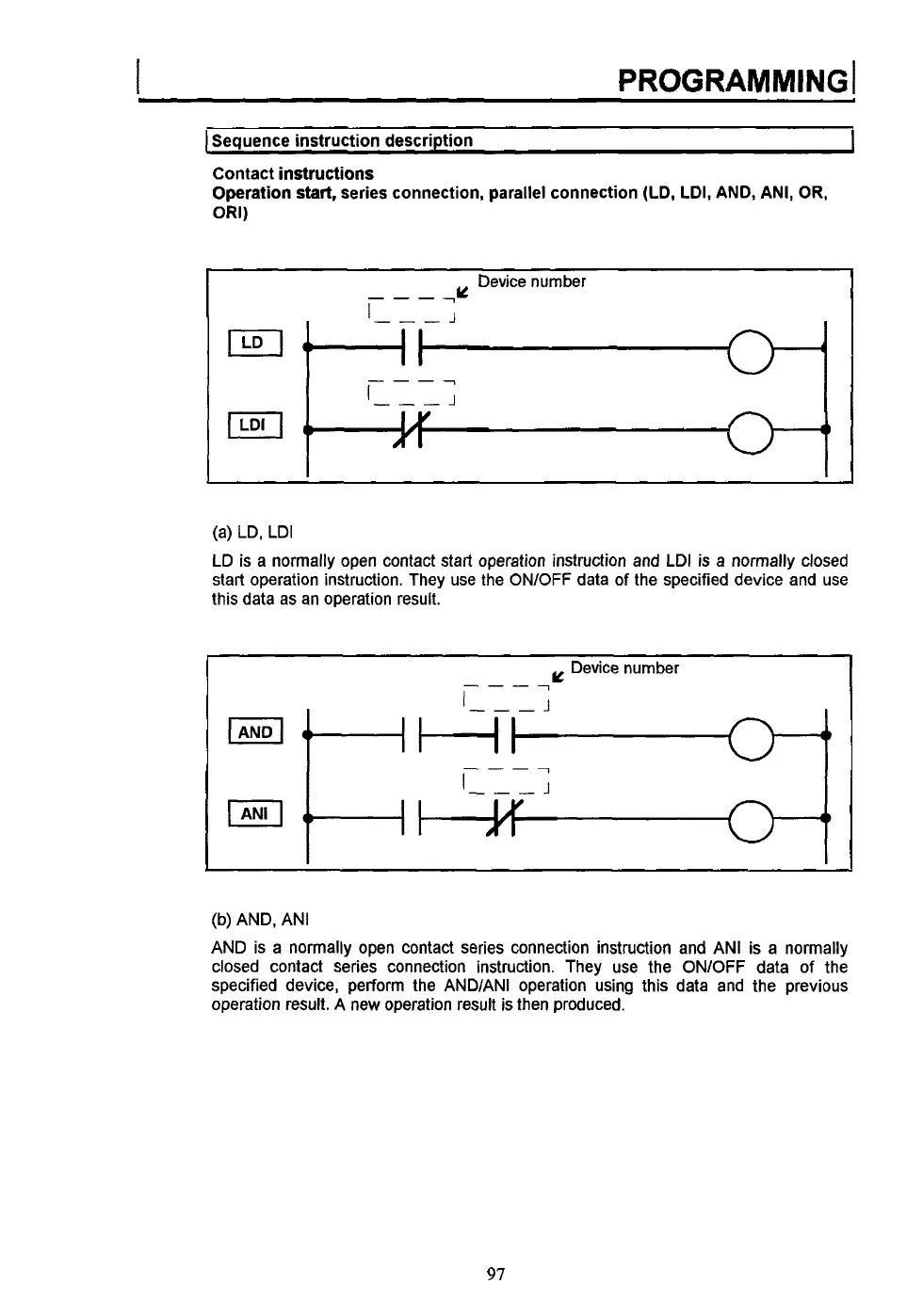

Contact instructions

Operation start, series connection, parallel connection

(LD, LDI, AND, ANI, OR,

ORI)

Device number

___

I

I

(a) LD, LDI

LD is a normally open contact start operation instruction and LDI is a normally closed

start operation instruction. They use the ON/OFF data

of

the specified device and use

this data as an operation result.

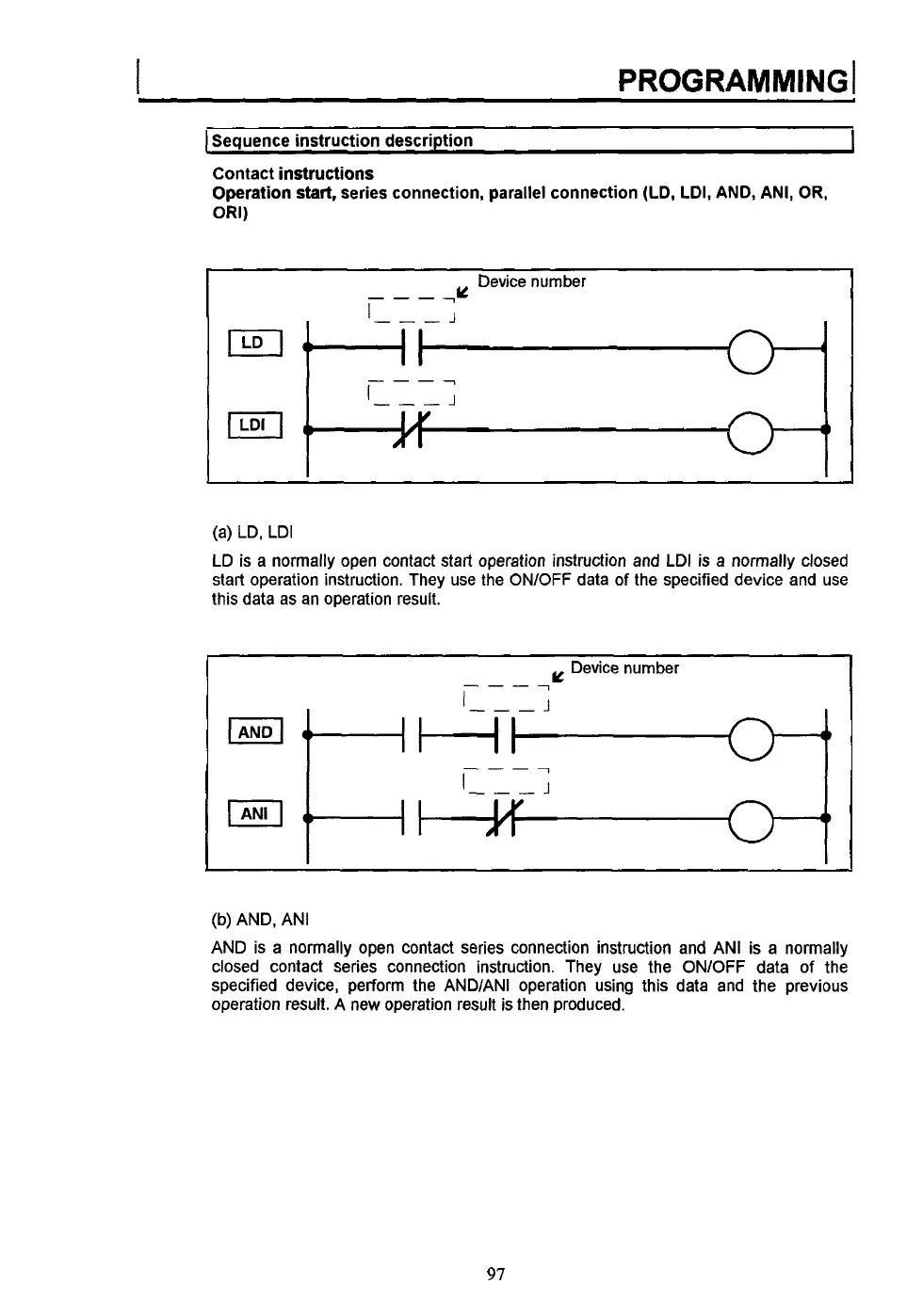

(b) AND, ANI

AND is a normally open contact series connection instruction and ANI is a normally

closed contact series connection instruction. They use the ONlOFF data of the

specified device, perform the AND/ANI operation using this data and the previous

operation result. A new operation result is then produced.

97

Loading...

Loading...