i

PROGRAMMING

I

I

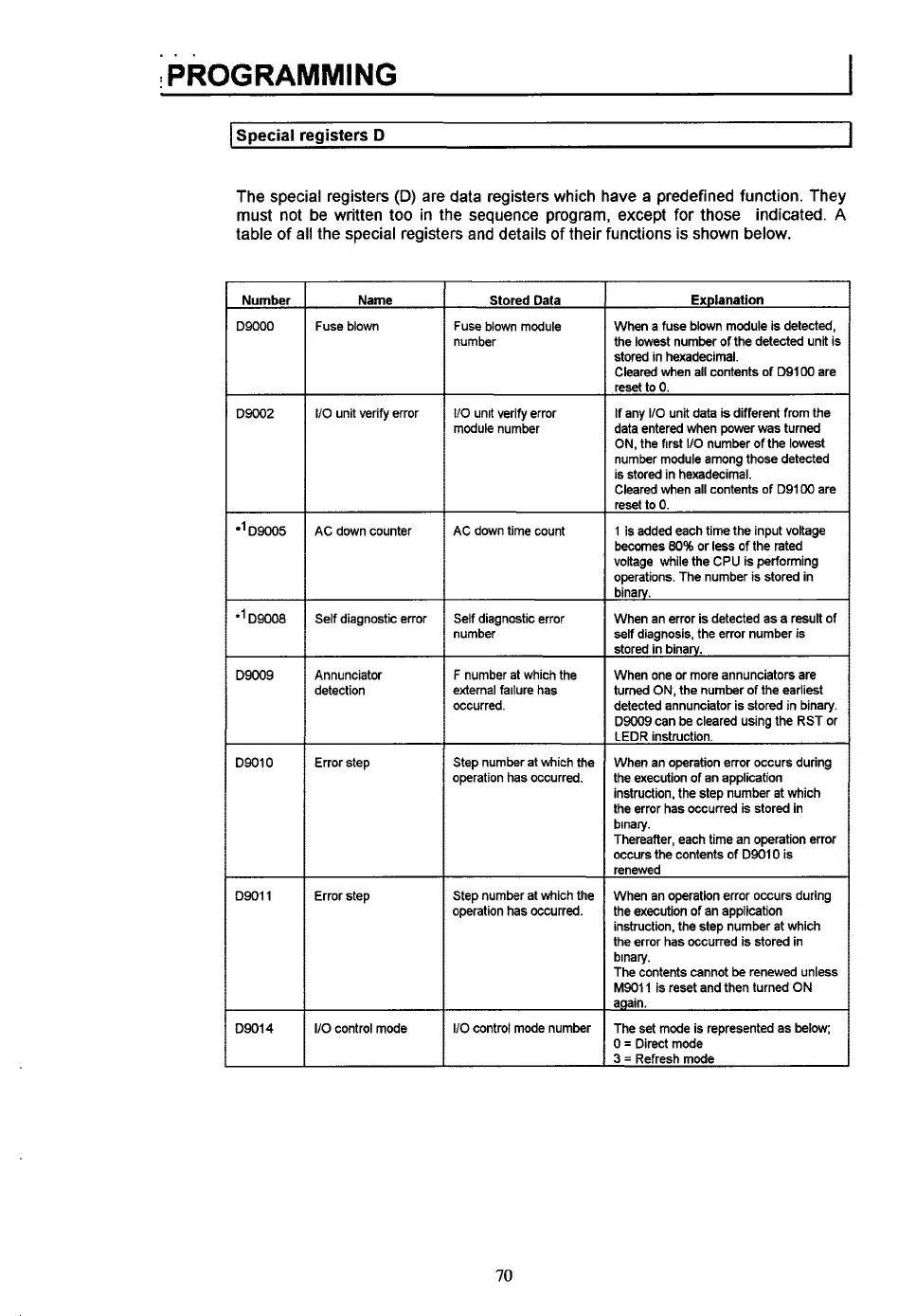

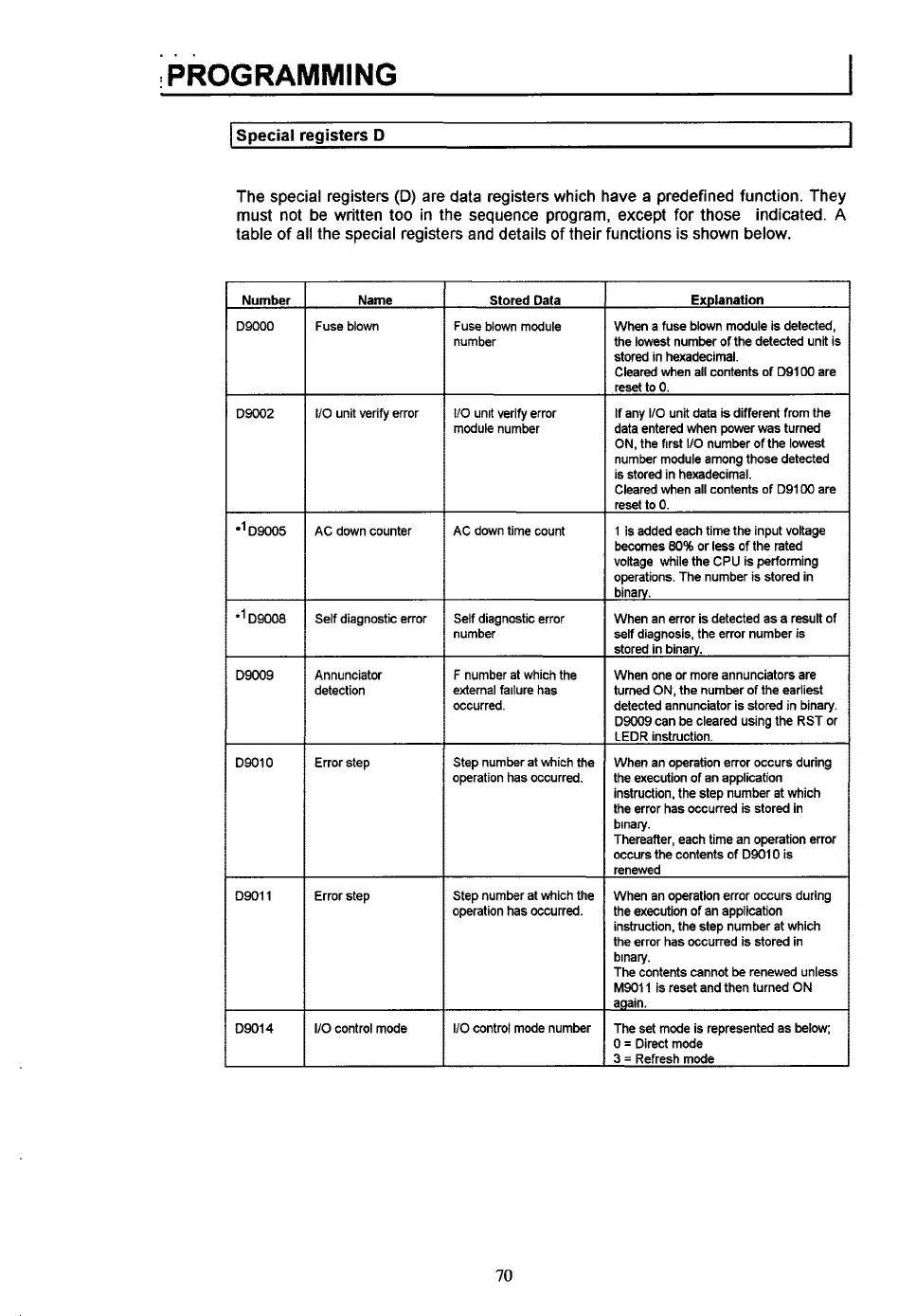

Soecial reaisters

D

I

The special registers

(D)

are data registers which have a predefined function. They

must not be written

too

in

the

sequence program, except for those indicated.

A

table

of

all

the

special registers and details

of

their functions is shown below.

Number

D9000

D9002

D9005

*'D9008

D9009

D9010

D9011

D9014

Name

Fuse blown

I/O unit verify error

AC down counter

Self

diagnostic error

Annunciator

detection

Error step

Error step

I/O

control mode

Stored Data

Fuse blown module

number

110

unit verify error

module number

AC down time count

Self diagnostic error

number

F

number at which the

external failure has

occurred.

Step number at which the

operation has occurred.

Step number at which the

operation has occurred.

110

control mode number

Explanation

When

a

fuse blown module is detected,

the

lowest

number

of

the detected unit is

stored in hexadecimal.

Cleared when all contents of D91W are

reset

to

0.

If any

110

unit data is different from the

data entered when power was turned

ON, the first

110

number

of

the lowest

number module among those detected

is stored in hexadecimal.

Cleared when all contents of D91W are

reset

to

0.

1 is added each time the input voltage

becomes

80%

or

less

of the rated

voltage while the

CPU

is performing

operations. The number is stored in

binary.

When an error is detected as a result of

self diagnosis, the error number is

stored in binarv.

When one or more annunciators are

turned

ON,

the number of the earliest

detected annunciator is stored in binary.

D9009 can be cleared using the RST or

LEDR instruction.

When an operation error occurs during

the execution of an application

instruction, the step number at which

the error has occurred

is

stored in

binary.

Thereafter, each time an operation error

occurs the contents

of

D9010 is

renewed

When an operation error occurs during

the execution of an application

instruction, the step number at which

the error has occurred is stored in

binary.

The contents cannot be renewed unless

M9011 is reset and then turned

ON

again.

The set mode is represented as below;

0

=

Direct mode

3

=

Refresh mode

70

Loading...

Loading...