BALANCER CHAIN <4B12>

ENGINE OVERHAUL

11B-50

1. Wipe the dirt on the crankshaft sprocket and the

crankshaft using a rag, and then remove the

grease from the portion shown in the illustration.

NOTE: Remove grease to prevent a drop in the

coefficient of friction of the pressing portion

caused by adhesion of oil.

AK502753

AC

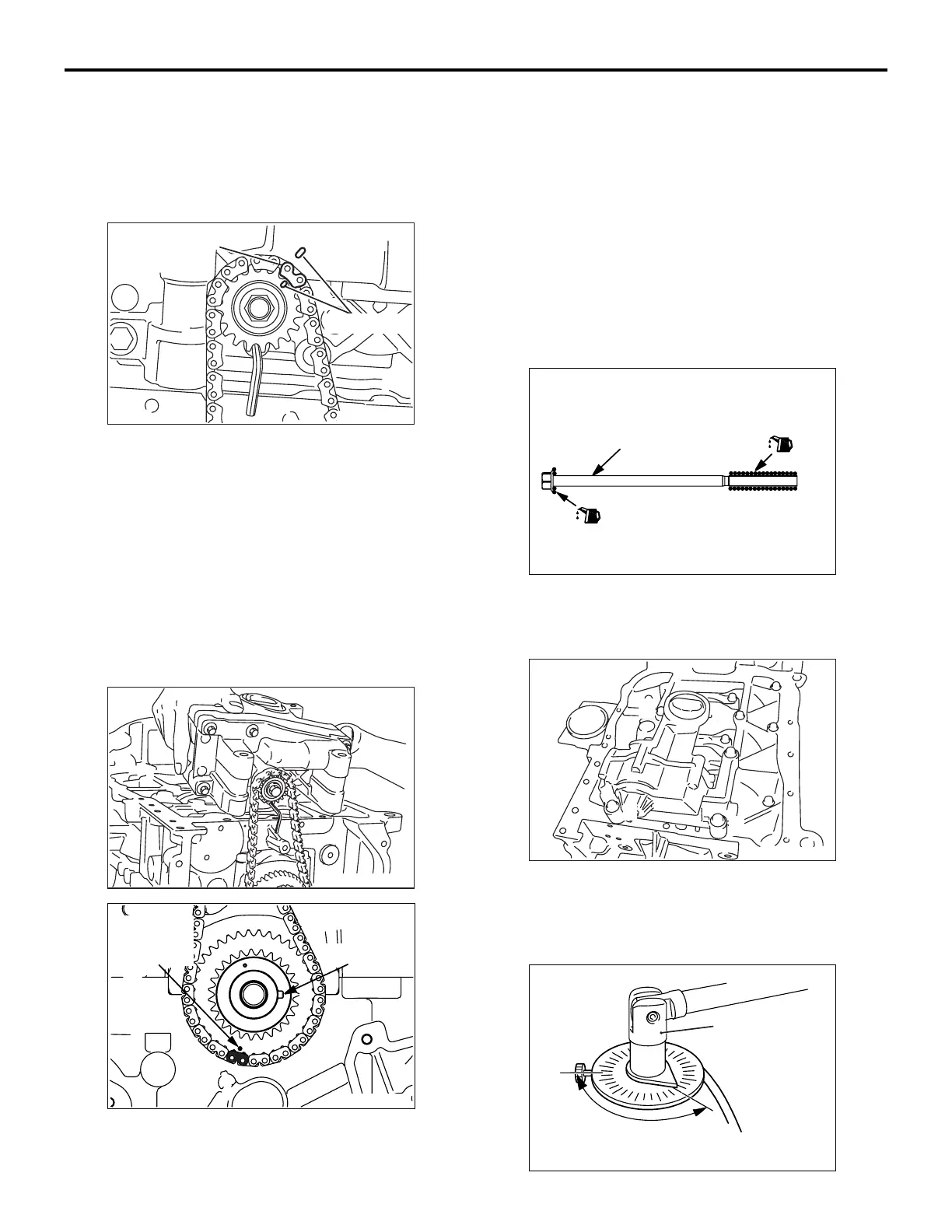

Timing mark

Balancer chain

link plate

(orange)

2. Align the timing mark of the balancer shaft module

sprocket with that of the balancer shaft module.

3. Insert a hexagonal bar wrench (3 mm) as

illustrated to prevent the balancer shaft module

sprocket from moving.

4. Loop the balancer chain, aligning its link plate

(orange) with the timing mark.

5. Install the crankshaft sprocket on the crankshaft.

NOTE: Do not push in the crankshaft sprocket to

the normal position. Push it in only up to the tip of

the crankshaft.

AK502754

AK503334

AC

Crankshaft

sprocket

timing mark

Key groove

6. While slanting the balancer shaft module, align

the link plate (blue) of another balancer chain with

the timing mark of the crankshaft sprocket to loop.

Gradually push in the crankshaft sprocket and fit it

into the key groove of the crankshaft. Then, install

the balancer shaft module on the ladder frame.

NOTE: Make sure that the balancer shaft module

is completely intimate contact with the ladder

frame.

NOTE: Make sure that the key groove of the

crankshaft is aligned with the contact surface of

the cylinder block and ladder frame as shown in

the illustration.

AK503386

AC

Balancer shaft

module bolt

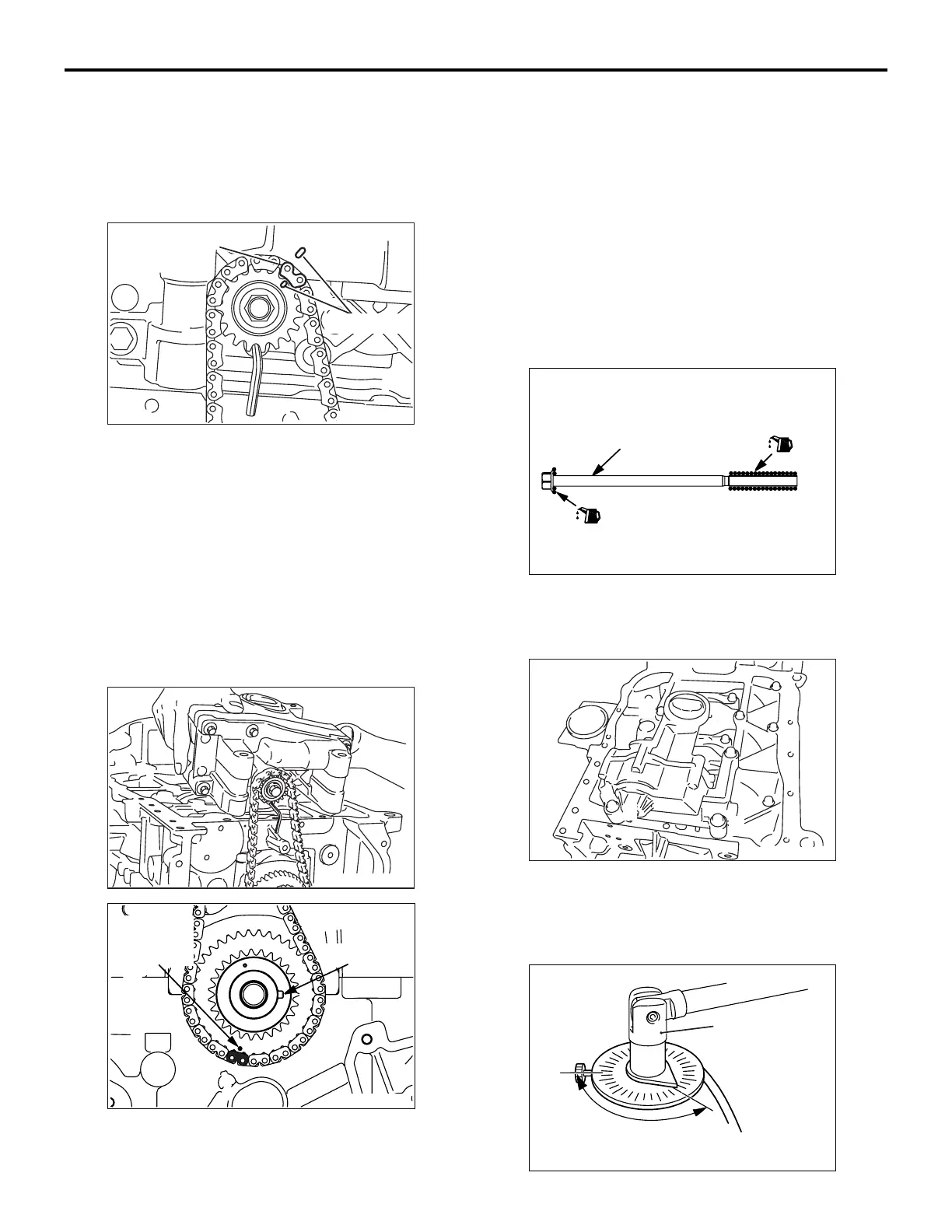

7. Apply an appropriate and minimum amount of

engine oil to the screw thread of the balancer

shaft module bolt.

AK502804

1

2

3

4

AC

8. Tighten bolts to the specified torque of 20 N⋅m

according to the assembly order in the illustration,

retighten them to 44 N

⋅m, and then completely

loosen them.

AK503158

AC

135˚

MB991614

Loading...

Loading...