Temposonics

®

E-Series CANopen

Operation Manual

11

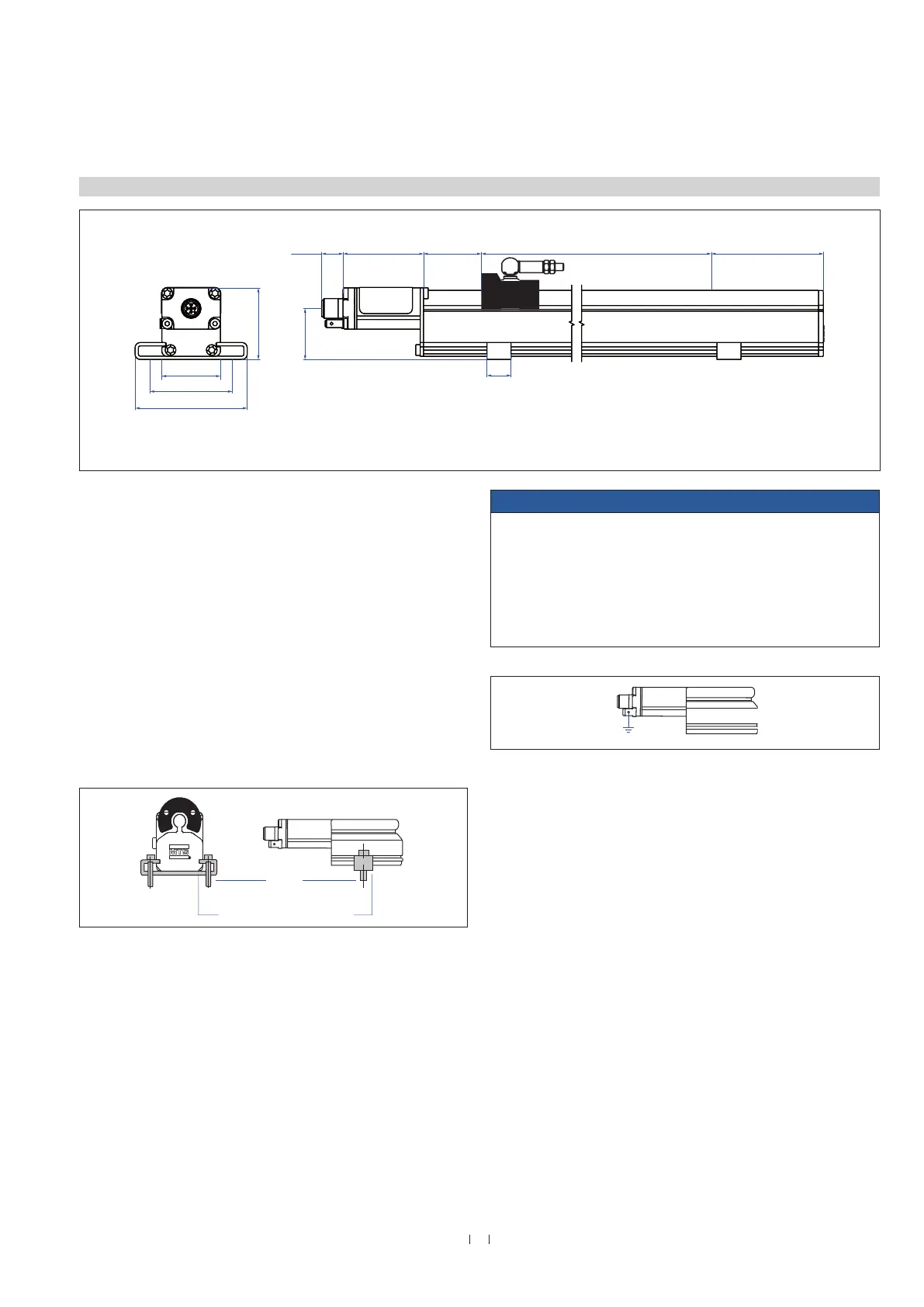

4.2 Styles and installation of E-Series EP

Magnet

50 (2)

68 (2.68)

Null zone

13

(0.52)

14.6

(0.57)

Stroke length

50…2540

(2…100)

Dead zone

68

(2.68)

31

(1.22)

43.4

(1.71)

35.6 (1.4)

Sensor electronics housing

48.8

(1.92)

35

(1.38)

Controlling design dimensions are in millimeters and measurements in ( ) are in inches

Unless otherwise stated, apply to the general tolerances according to DIN ISO 2768-m

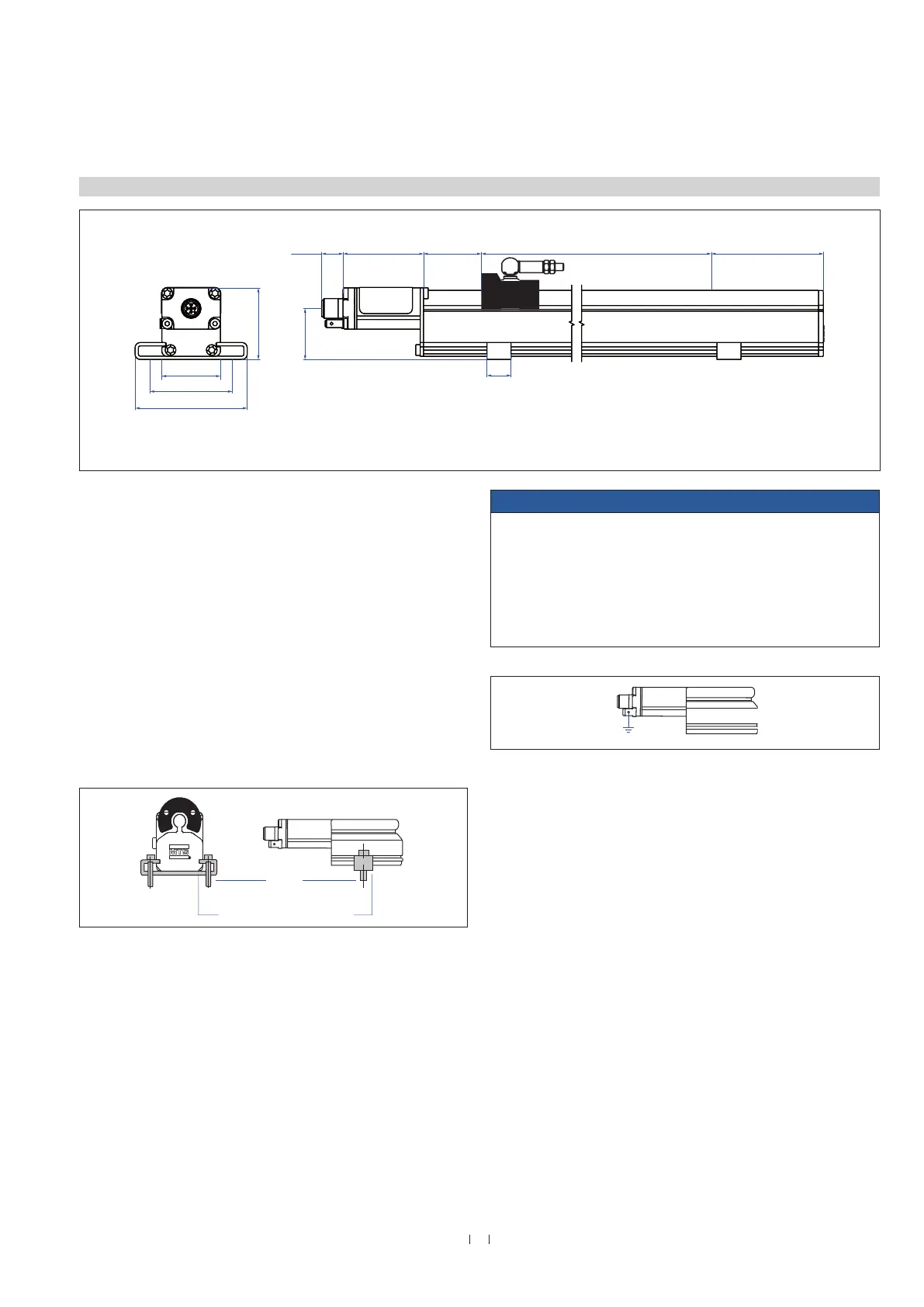

Installation of EP

The position sensor can be installed in any position. Normally, the

sensor is firmly installed and the position magnet is fastened to

the mobile machine part. Thus it can travel along the sensor rod

contactlessly.

The sensor is fitted on a flat machine surface using mounting clamps

(Fig. 4). A length-dependent number of these clamps are delivered

with the sensor and must be distributed over the profile at regular

distances.

For fastening, we recommend using M5×20 screws according to

DIN 6912 that should be tightened with a maximum fastening torque

of 5 Nm.

Adjustable mounting clamps

M5×20

max. 5 Nm

Fig. 3: Temposonics

®

E-Series EP

NOTICE

Do not mount the sensors in the area of strong magnetic or electric

noise fields. Take care to mount the sensor in an axially parallel

position to avoid damaging the carriage, magnet and sensor rod.

The sensor is isolated from the machine ground. For this reason,

grouding via grounding lug on the sensor electronics housing is

indispensable (Fig. 5).

Fig. 4: Mounting clamps with cylinder screw M5×20, fastening torque ≤ 5 Nm

on a Temposonics

®

E-Series EP sensor with U-magnet

Fig. 5: Grounding profile sensor

Loading...

Loading...