ENGLISH – 17

EN

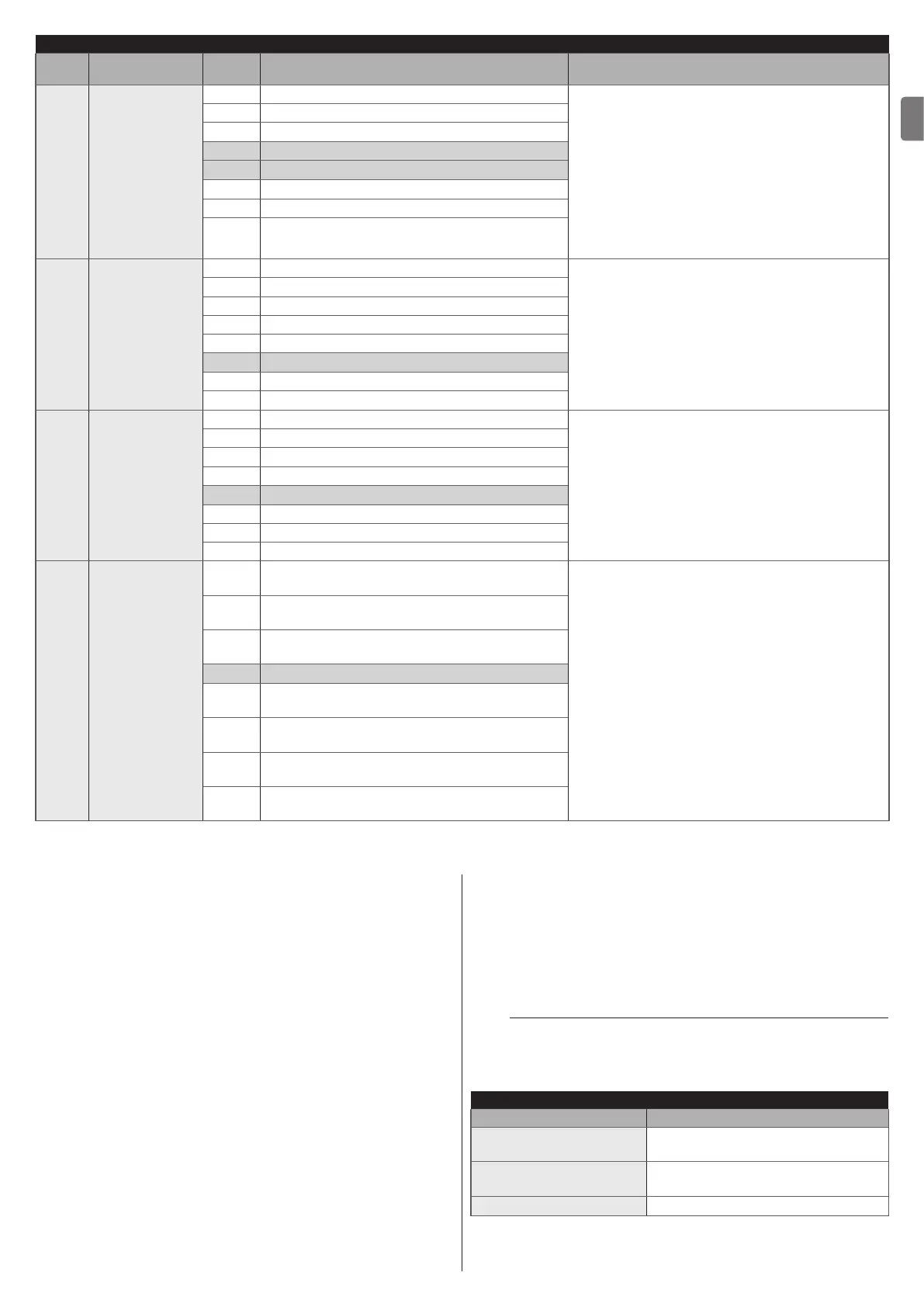

LEVEL 2 FUNCTIONS (ADJUSTABLE PARAMETERS)

Entry

LED

Parameter

LED

(level)

Set value Description

L5 Balancing

L1 0% - Decreases the closing duration Allows for increasing or decreasing the duration

of the closing manoeuvre. This is useful when

the motor moves in the two directions at different

speeds (for example, hydraulic motors) or when

the leaves are unbalanced and require different

force levels during the opening and closing

manoeuvres, covering the same distance with

different times.

If the closing manoeuvre must be increased, shift

the setting towards L8; if the closing manoeuvre

must be decreased, shift the setting towards L1.

L2 20 %

L3 30 %

L4 40 %

L5 60 %

L6 70 %

L7 80 %

L8 100% - Increases the closing duration

L6 Motor force

L1 25% - Minimum force

Adjusts the force of both motors through the

phase partialisation expressed in percentage.

L2 35 %

L3 45 %

L4 55 %

L5 65 %

L6 75 %

L7 85 %

L8 100% - Maximum force

L7 Start-up time

L1 0 s

Allows for programming the start-up duration at

the start of a manoeuvre.

L2 0.5 s

L3 1 s

L4 1.5 s

L5 1.8 s

L6 2 s

L7 2.5 s

L8 3 s

L8

Pedestrian or

partial opening

L1

Pedestrian 1 (the M2 gate leaf opens to 1/4 of

the full length)

Adjusts the type of opening associated with the

“partial opening 1” command.

In levels L5, L6, L7 and L8, “minimum” opening

refers to the smallest opening between M1 and

M2; for example, if M1 opens to 90° and M2

opens to 110°, the minimum opening is 90°.

L2

Pedestrian 2 (the M2 gate leaf opens to 1/2 of

the full length)

L3

Pedestrian 3 (the M2 gate leaf opens to 3/4 of

the full length)

L4 Pedestrian 4 (full opening of gate leaf 2)

L5

Partial 1 (the two gate leaves open to 1/4 of the

“minimum” opening level)

L6

Partial 2 (the two gate leaves open to 1/2 of the

“minimum” opening level)

L7

Partial 3 (the two gate leaves open to 3/4 of the

“minimum” opening level)

L8

Partial 4 (the two gate leaves open to the

“minimum” opening level)

6.4 SPECIAL FUNCTIONS

6.4.1 “Move anyway” function

This function can be used to operate the automation even one

or more some safety devices fail to work properly or are out of

order. The automation can be controlled in “hold-to-run” mode

by proceeding as follows:

1. send a command to operate the gate, using a transmitter

or key selector, etc. If everything functions properly, the

gate will move normally, otherwise proceed with point 2

2. within 3 seconds, press the control again and hold it down

3. after roughly 2 seconds, the gate will complete the re-

quested manoeuvre in “hold-to-run” mode, in other

words, it will continue to move so long as the control is

held down.

6.4.2 “Maintenance notice” function (congurable with

an external programmer)

This function allows for signalling to the user when the auto-

mation needs maintenance. The maintenance signal is given

through a lamp connected to the “OGI” output, if this output is

congured as a “Maintenance indicator”.

The conguration is only possible through the “Oview” program-

mer (refer to the “Connecting the IBT4N interface” paragraph).

l

The various indicator lamp signals are shown in “

Table 7”.

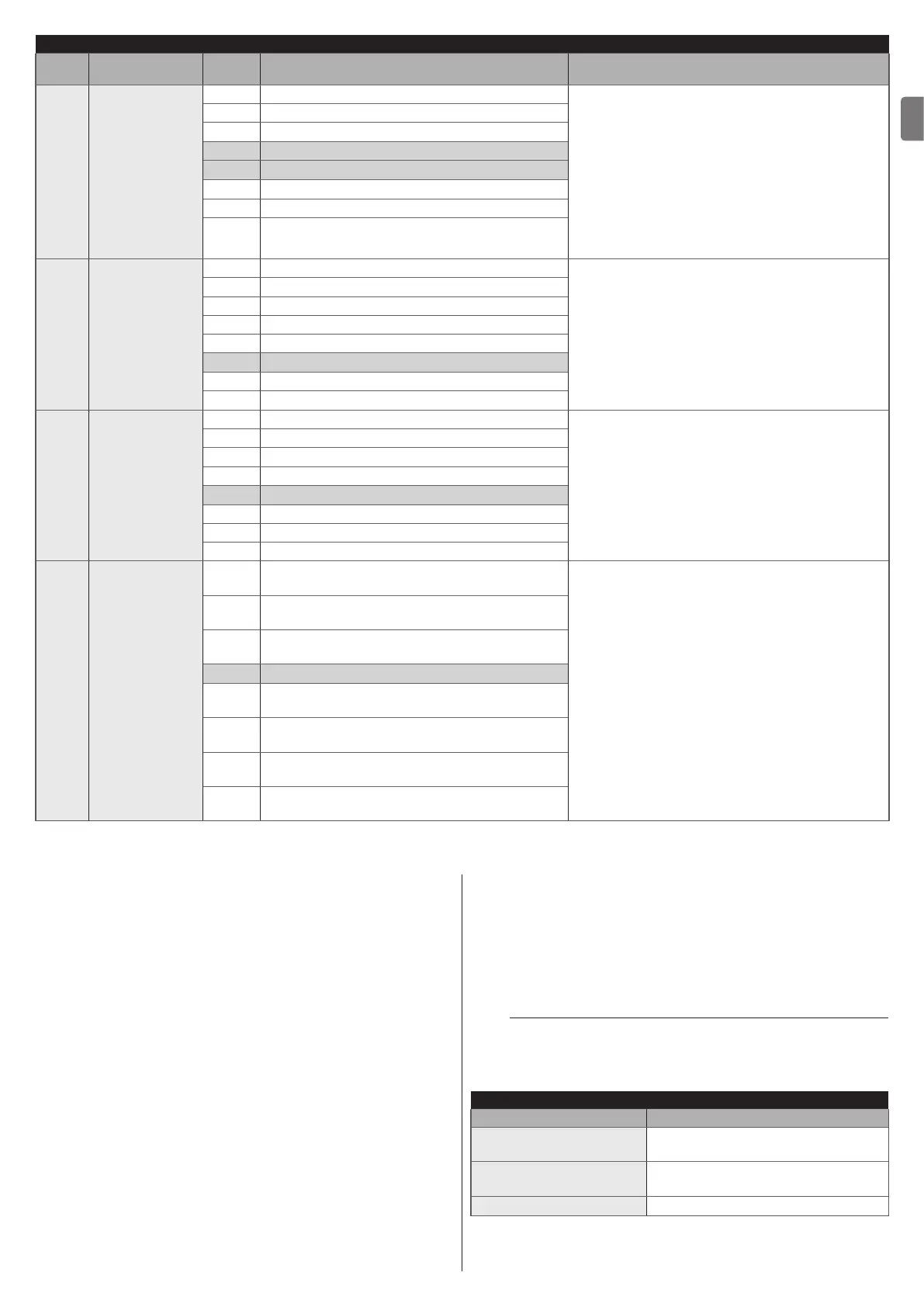

Table 7

“MAINTENANCE INDICATOR” SIGNAL

Number of manoeuvres Signal

Below 80% of the limit

Lamp stays lit for 2 seconds at the

start of the opening manoeuvre.

Between 81% and 100%

of the limit

Lamp ashes for the entire duration

of the manoeuvre.

Over 100% of the limit

Lamp ashes continuously.

Loading...

Loading...