English – 35

This user guide should be stored and handed to all users of the automation.

WARNINGS

q6GDMXNTjQRSTRDSGD@TSNL@SHNMSGDHMRS@KK@SHNMSDBGMHBH@MLTRSHMENQLXNT@ANTSSGDNQHFHMNESGDQDRHCT@KQHRJR@MCXNTLTRSS@JDSHLDSNQD@CSGDTRDQ

manual, with special attention to the general warnings (instruction manual).

• Make sure to keep the manual (delivered by the installation technician) for future reference and for handover to any further owner of the automation.

• Your automation system is a machine that will faithfully execute your commands; unreasonable or improper use may make it dangerous: do not operate the

system if there are people, animals or objects within its range of operation.

• Children: automation systems are designed to guarantee high levels of safety and security. They are equipped with detection devices that prevent move-

ment if people or objects are in the way, guaranteeing safe and reliable activation. However, it is advisable to avoid letting children play in the vicinity of the

@TSNL@SHNM@MCQDLNSDBNMSQNKRRGNTKC@KV@XRADJDOSNTSNESGDHQQD@BGlHSHRMNS@SNXŬ

• Check the installation, with special attention to the cables, springs and supports, to detect possible imbalances, and signs of wear or damage.

– Check on a monthly basis that the gearmotor performs a reverse manoeuvre when the garage door touches an object with a height of 50 mm.

– Do not use the automation if repairs or adjustments are required; any fault or an incorrectly balanced garage door may lead to physical injury.

• Malfunctions: if the automation is malfunctioning, shut off its power supply. Never attempt any repairs; contact your local installer for assistance.

– The system can be operated manually: release the gearmotor, as described in “Manual release and lock”.

– Do not modify the system or its programming and adjustment parameters in any way: your installer is exclusively responsible for these operations.

l3GDjM@KSDRSODQHNCHBL@HMSDM@MBD@MC@MXQDO@HQRLTRSADCNBTLDMSDCAXSGDODQRNMVGNODQENQLDCSGDL@MCSGDQDK@SHUDCNBTLDMSRLTRSADRSNQDC

by the owner of the system.

q#HRONR@K SSGDDMCNESGD@TSNL@SHNMRKHEDDMRTQDSG@SHSHRCHRONRDCAXPT@KHjDCODQRNMMDK@MCSG@SSGDL@SDQH@KR@QDQDBXBKDCNQRBQ@OODC@BBNQCHMFSN

current local regulations for this product category.

• Control with safety equipment deactivated: the system can be controlled even if the safety equipment is not operational.

(ESGDk@RGDQk@RGDRRDUDQ@KSHLDRVGDM@BNLL@MCHRFHUDMSGDMTLADQNEk@RGDRCDODMCRNMSGDB@TRDNESGDL@KETMBSHNMATSSGDCNNQCNDRMNSQD-

spond, proceed as follows:

within 3 seconds, hold down a control; after 2 seconds the movement will start in ‘hold-to-run’ mode and will continue until you release the control.

Important: have the system repaired as soon as possible if the safety devices are malfunctioning.

‘Transit is allowed only if the door is open and stationary’.

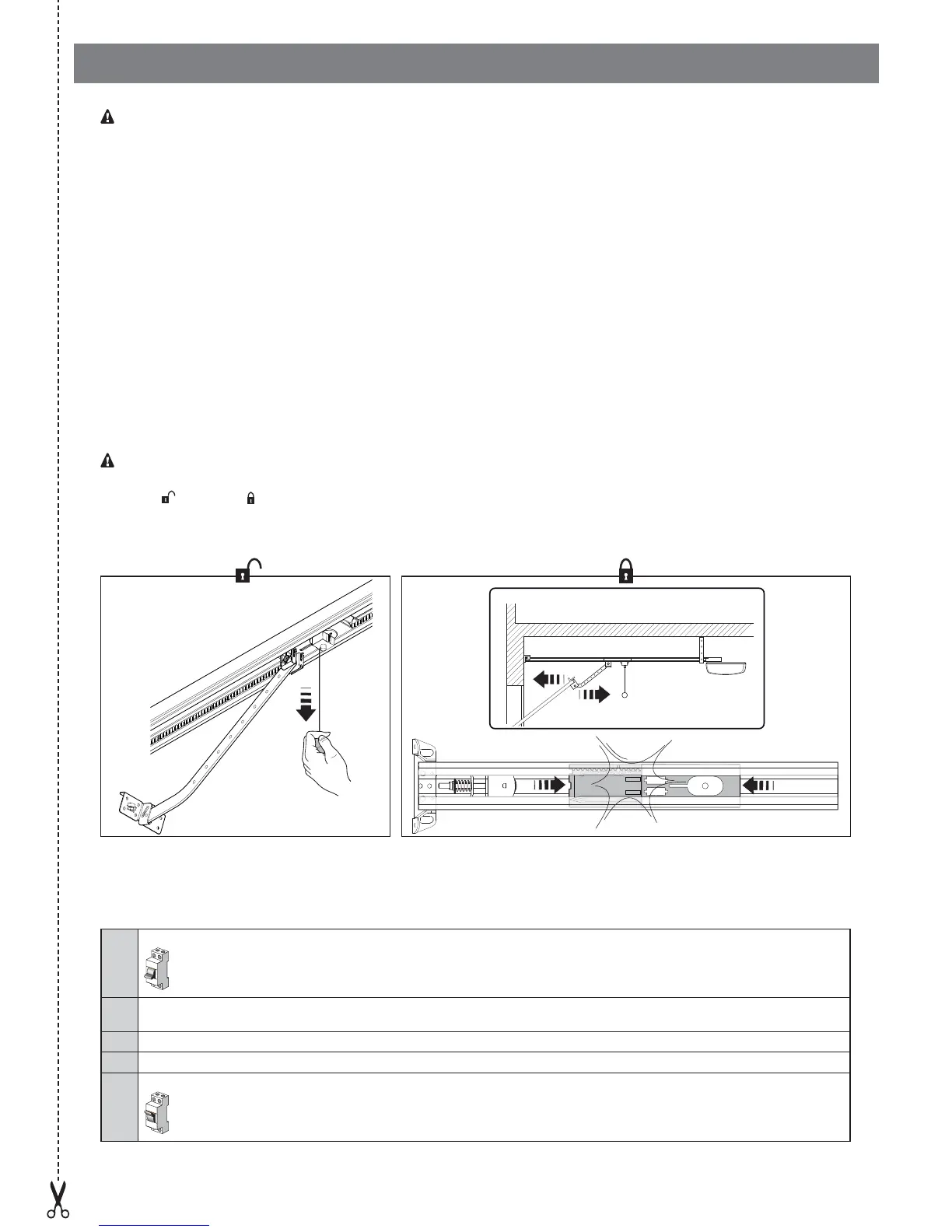

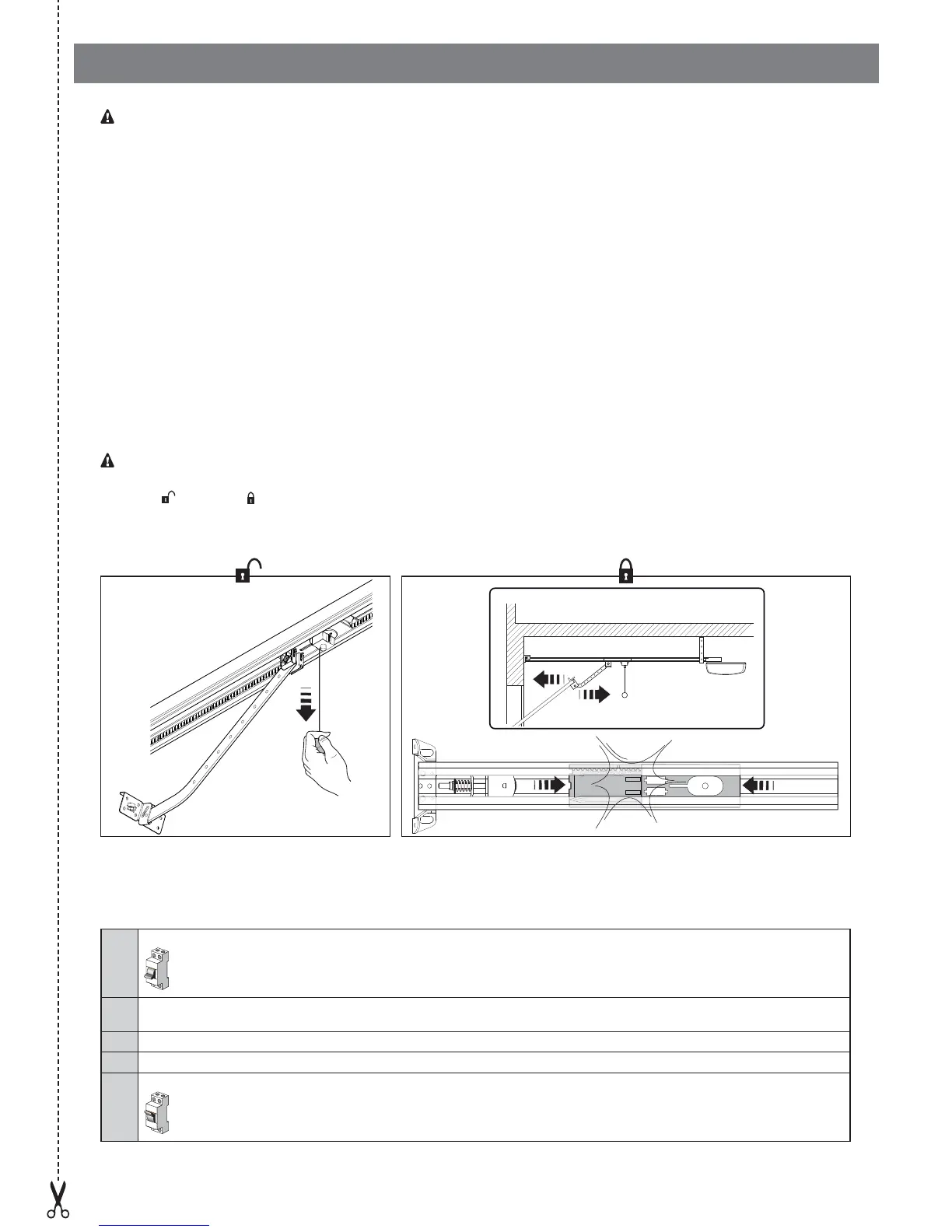

Unlocking and locking the gearmotor (manual operation)

1. Pull the release cord down until you hear the release of the carriage.

2. The door can now be moved manually

3. To restore automation operation return the door to the initial position until you hear the carriage engage.

CLAK

Maintenance

To ensure that no one can activate the garage door, before you begin, remember to lock the automation (as described in “Manual gearmotor release

and lock”) and disconnect all power sources.

In order to ensure constant levels of safety and the maximum useful life of the automation, it must undergo programmed maintenance work every 6

months.

01.

OFF

+ any backup batteries present

02.

Check for any deterioration in automation system components, paying special ATTENTION to erosion or oxidation of the structural parts.

Replace any parts which are below the required standard.

03. Check the wear and tear of the moving parts.

04. Clean the guide with a dry cloth to remove any dirt.

05.

ON

Run all the tests and checks indicated in par. 7.1.

USER GUIDE (to be handed to the end user)

Loading...

Loading...