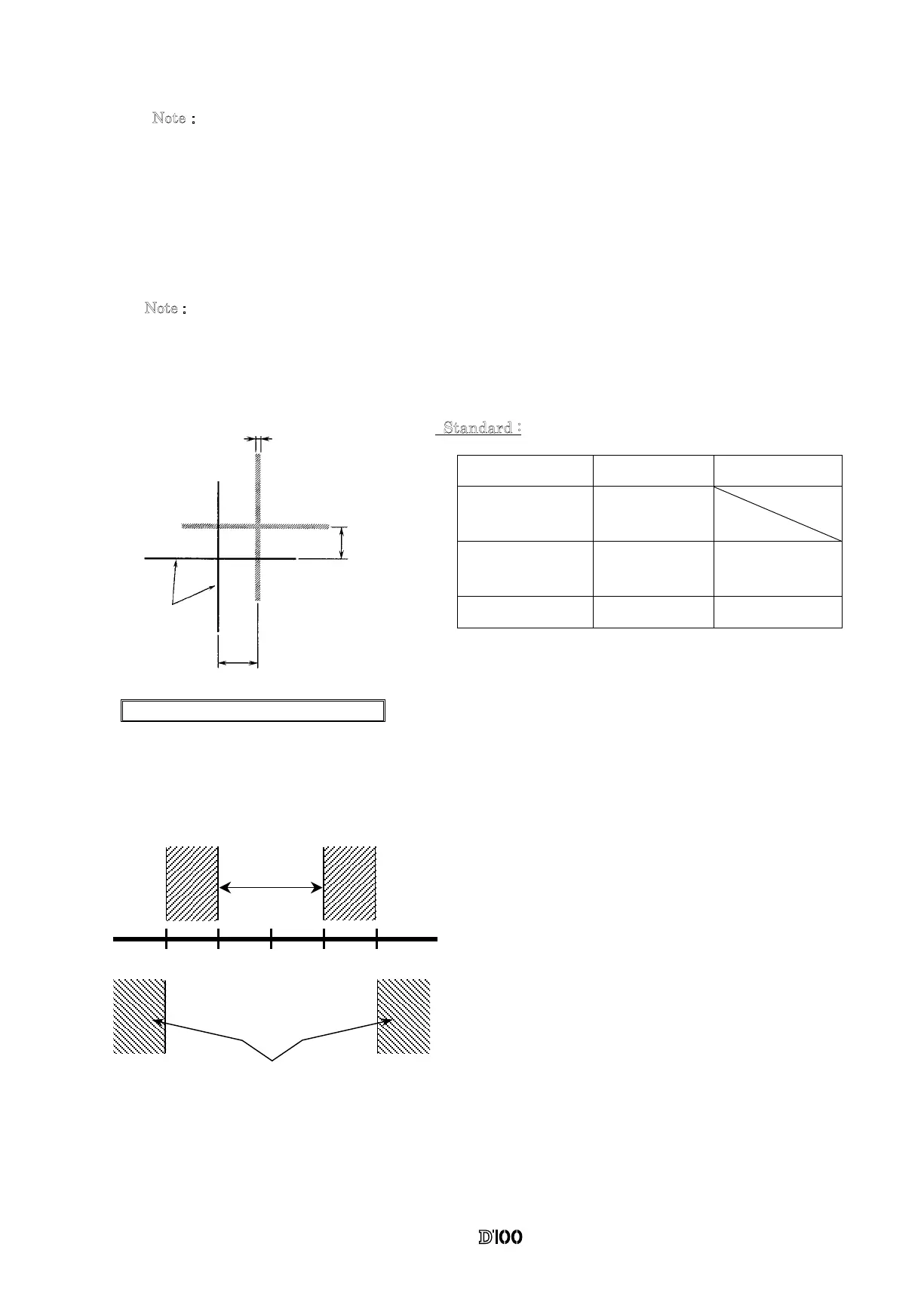

Angle adjustment of main mirror to 45

NoteCheck to confirm the accuracy of the main mirror before and after adjustment by

moving it up and down several times.

Checking the discrepancy (right/left)

If horizontal displacement is out of the standard value, it is possible that bayonet spring

#112 is pinched, mirror unit B2231 is defective, or mirror shaft is bent.

Checking the discrepancy (up/down)

If the amount of the discrepancy is out of the standard value, rotate the main mirror

eccentric pin to adjust.

Angle adjustment of sub mirror to 4547.75

NoteCheck to confirm the accuracy of the main mirror before and after adjustment by moving

it up and down several times.

Checking the discrepancy (up/down)

If the amount of the discrepancy is out of the standard value, rotate the sub mirror eccentric

pin to adjust.

Standard

up/down

right/left

Line width is distortion

Standard :

20

5 5

8 8

�

�

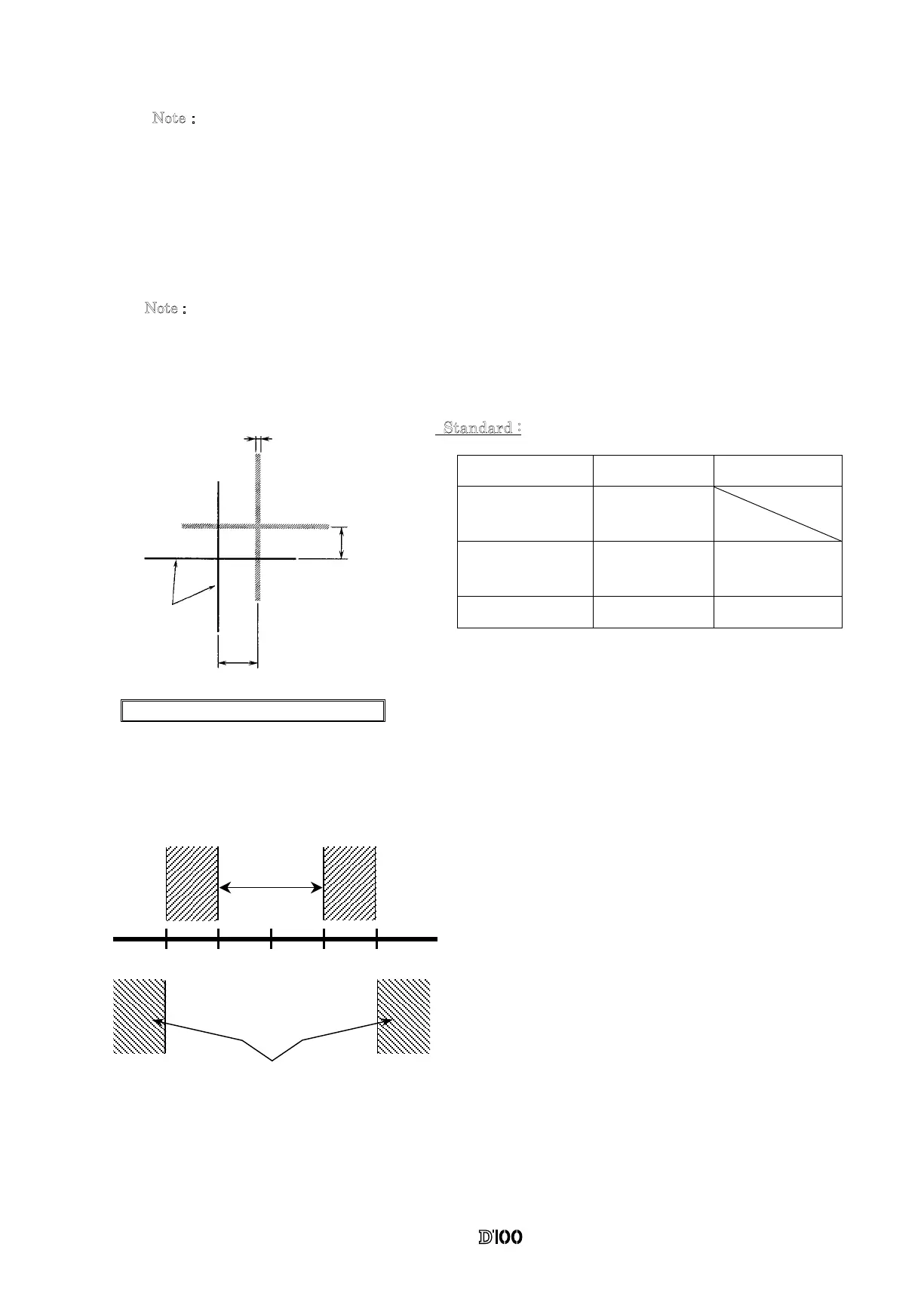

ADJUSTMENT OF INFINITY

0.15 0.10 0 +0.10 +0.15

standard

(mm)

Check for the deformation of the front body or

Prism box.

Replace the screen by the screen J15371

(Common to the screen of F601M).

Connect the SI translucent tool J15370 to the SI

LCD FPC using the clip connector J15376. Then,

turn on the power of the tool as described page A12.

Set the reference lens J18010 and read the value.

In the case of -0.10+0.10

As it is within the standard range, adjustment is

not required.

In the case of -0.150.10 or +0.10+0.15

Replace the G3 washer #297.

In the case of -0.15 or less or +0.15 or more

Check for the deformation of the front body or

Prism

box.

Loading...

Loading...