2

8

➜

➜

➜

➜

2.4

2.5

36 2000

50 1500

70 800

95 400

115 300

155 100

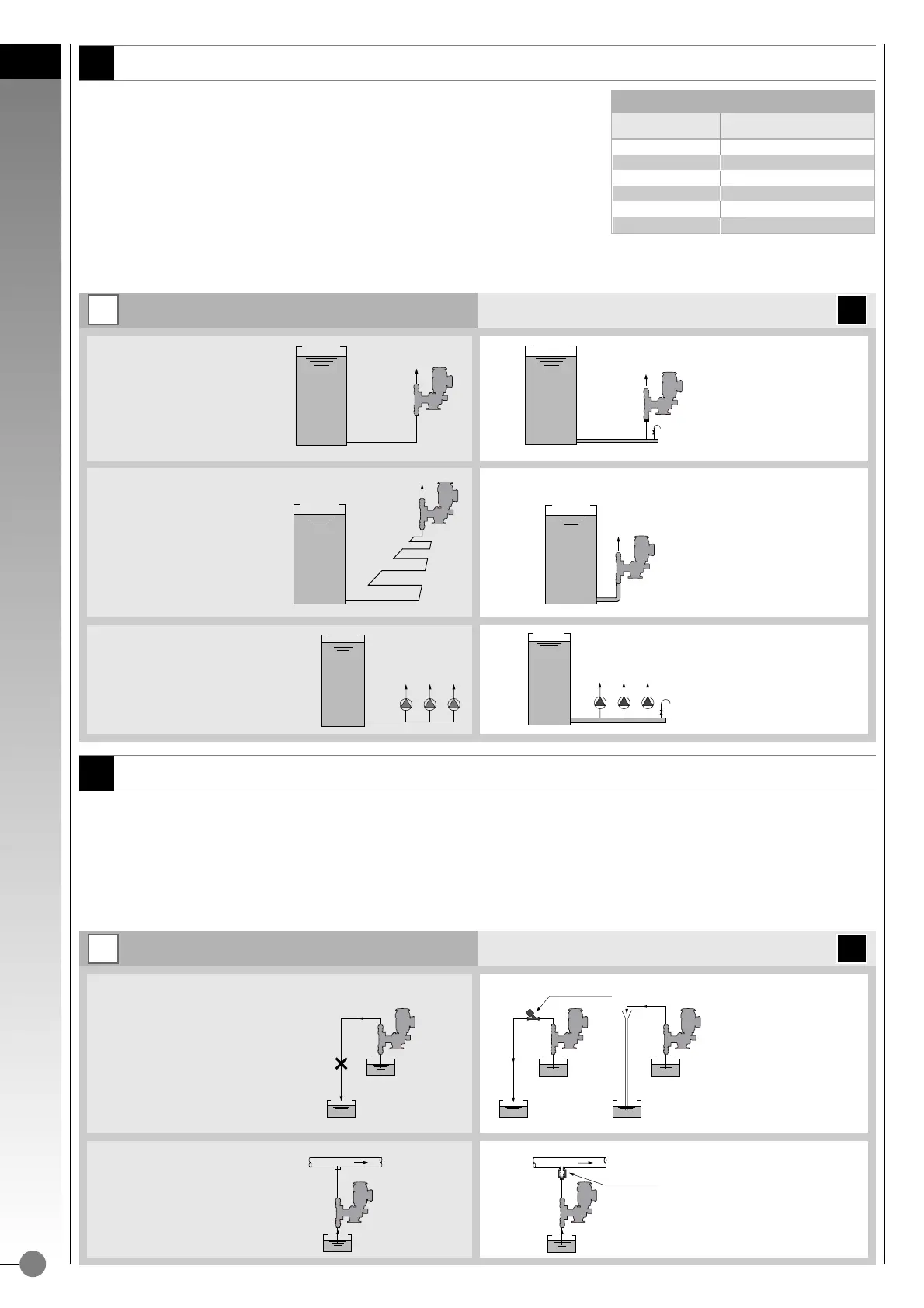

Fig. 9

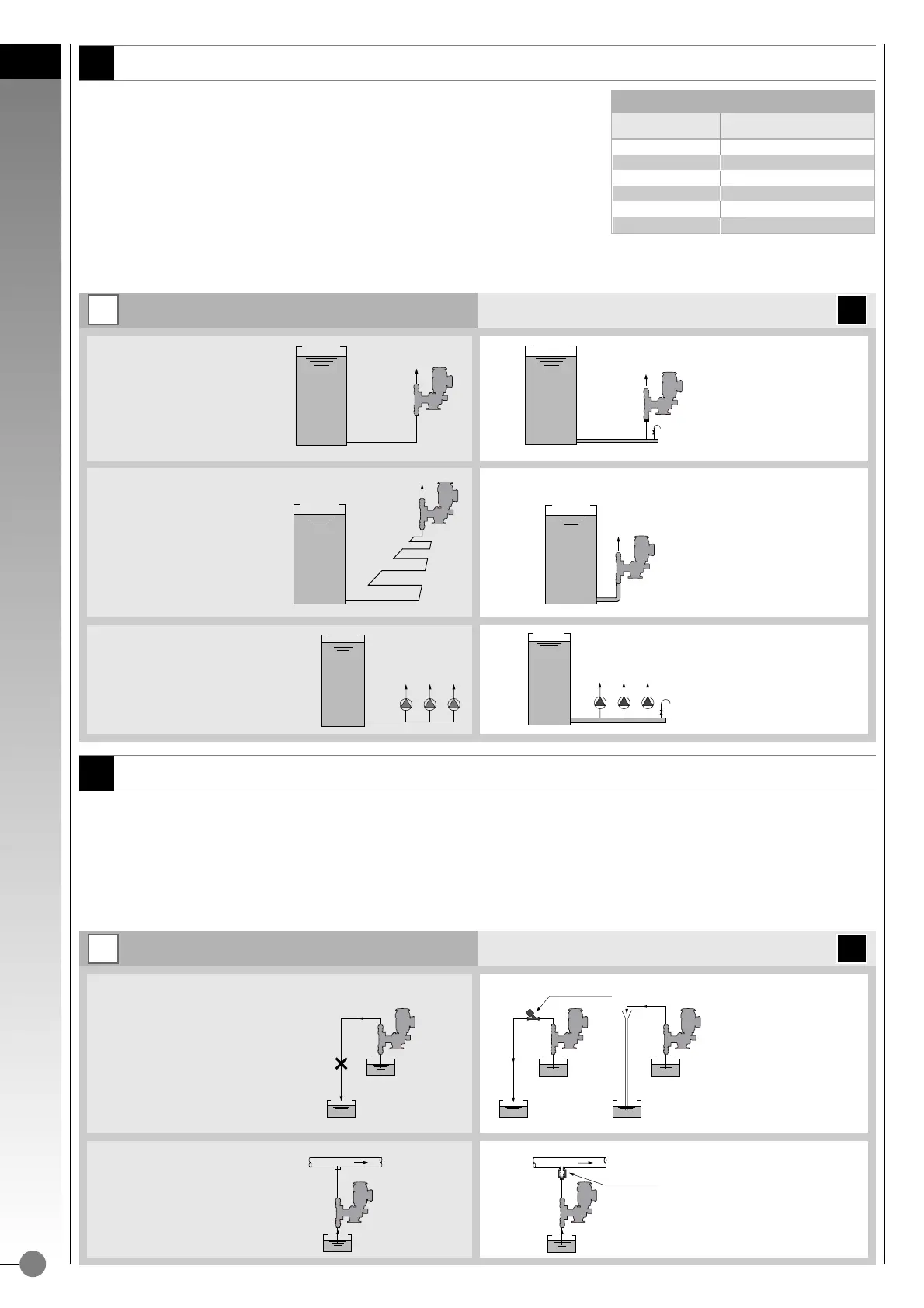

Fig. 10

RIGHTWRONG

INJECTION

NOZZLE

BACKPRESSURE

VALVE

Right

Right

Wrong

Siphoning.

Uncontrollable flow rate

.

Wrong

Failing a back pressure valve, the

flow in pipeline “A” draws the

product from the tank in an

uncontrolled way.

• When the free surface of the liquid in the suction side tank is above discharge-side tank level, an uncontrollable flow from the suction

side tank to the discharge side tank will occur.

• To prevent this natural passage of liquid, the discharge pressure must always be at least 0,3 Kg/cmq, higher than the suction pres-

sure, in case of small flow rates 0,5 Kg/cmq.

• If for any reason this condition cannot be complied with the plant it is necessary to create a backpressure by means of a suitable

valve, or better to highten the discharge pipe so as to prevent the siphoning effect (fig.10).

DISCHARGE LINE

RIGHTWRONG

Recommended

Recommended

Right

Wrong

Wrong

Wrong

S.P.M. cp max execution "A"

Table E

Relationship between strokes per minute "SPM" and

viscosity of the liquid "cp", valid for AISI 316L or PP.11

pump heads.

• Specific technical information is required for the installation of pumps intended for

metering viscous liquids.

- For this kind of application we recommend stainless steel pumpheads.

- The suction piping must have an adequate diameter; as a rule, for high-viscosity liq-

uids (2000 cps), select the size immediately above the diameter of the pump suction

connections.

- In any case, when viscous liquids are to be metered choose for the pipe at least the

same size as that of the pump connections.

Examples of installation for viscous liquids

INSTALLATION

SUCTION PIPING FOR VISCOUS LIQUIDS

Loading...

Loading...