4

13

4.1

4

15

5

15

5

15

5

15

5

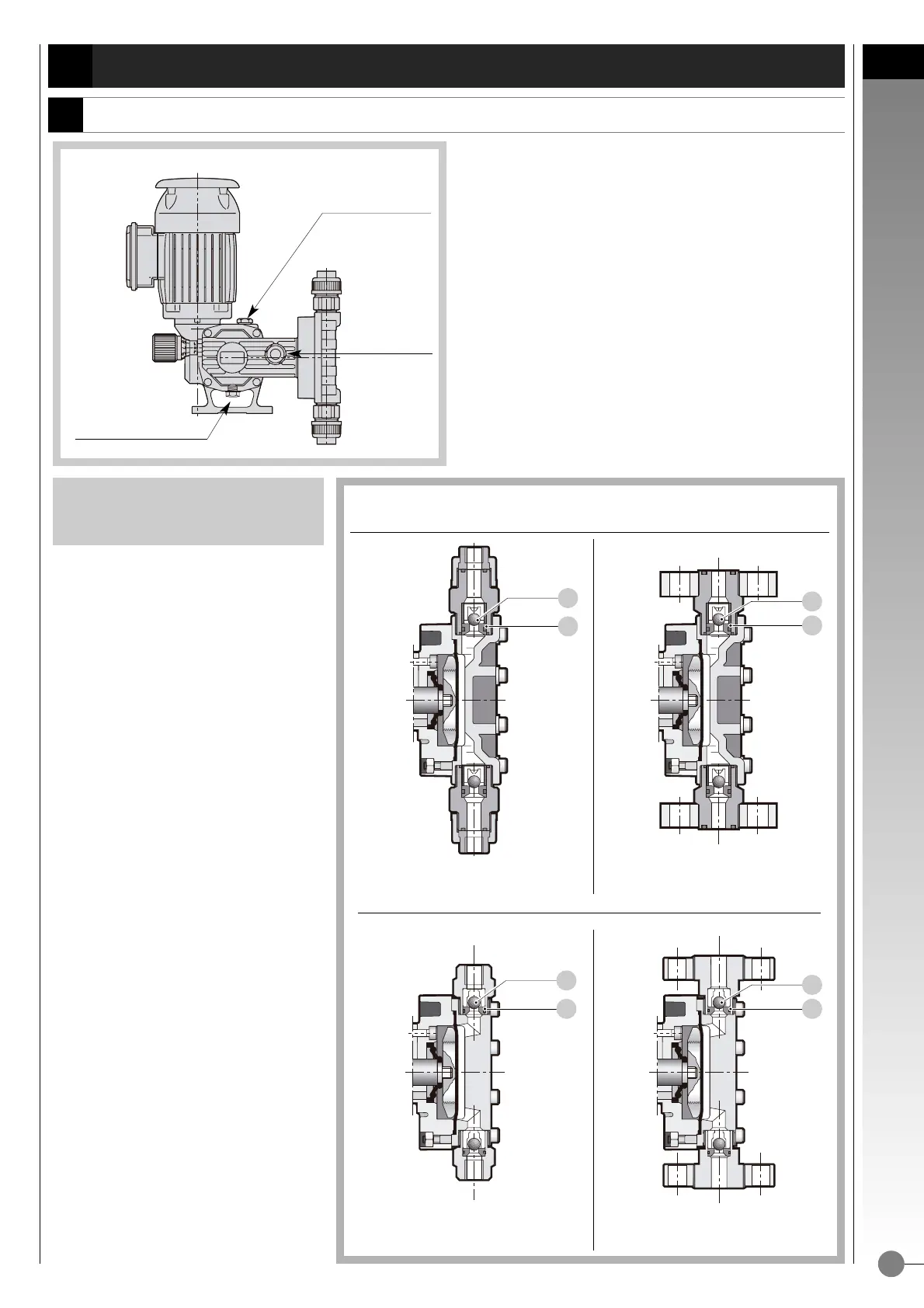

Fig. 17

Fig. 16

AISI 316L head “A” execution, flanged connections.

AISI 316L head “A” execution, threaded connections.

PP head “PP” execution, flangeded connections.

PP head “PP” execution, threaded connections.

PROPER ARRANGEMENT OF:

-Valves pos. 15

-Seal pos. 5

• Refer first to the pumphead section

drawing.

• Pay attention to the arrangement of the

valve components; each valve ball rests by

gravity on its seat (Figure 17).

• Unscrew the suction and discharge valve

units, one at a time. Check their components

for soundness and cleanness.

• Clean carefully all valve components: seat,

ball, guide, housing.

In case of lower or irregular flow rate,

check the valve units as follows

:

MAINTENANCE

MAINTENANCE

ROUTINE MAINTENANCE

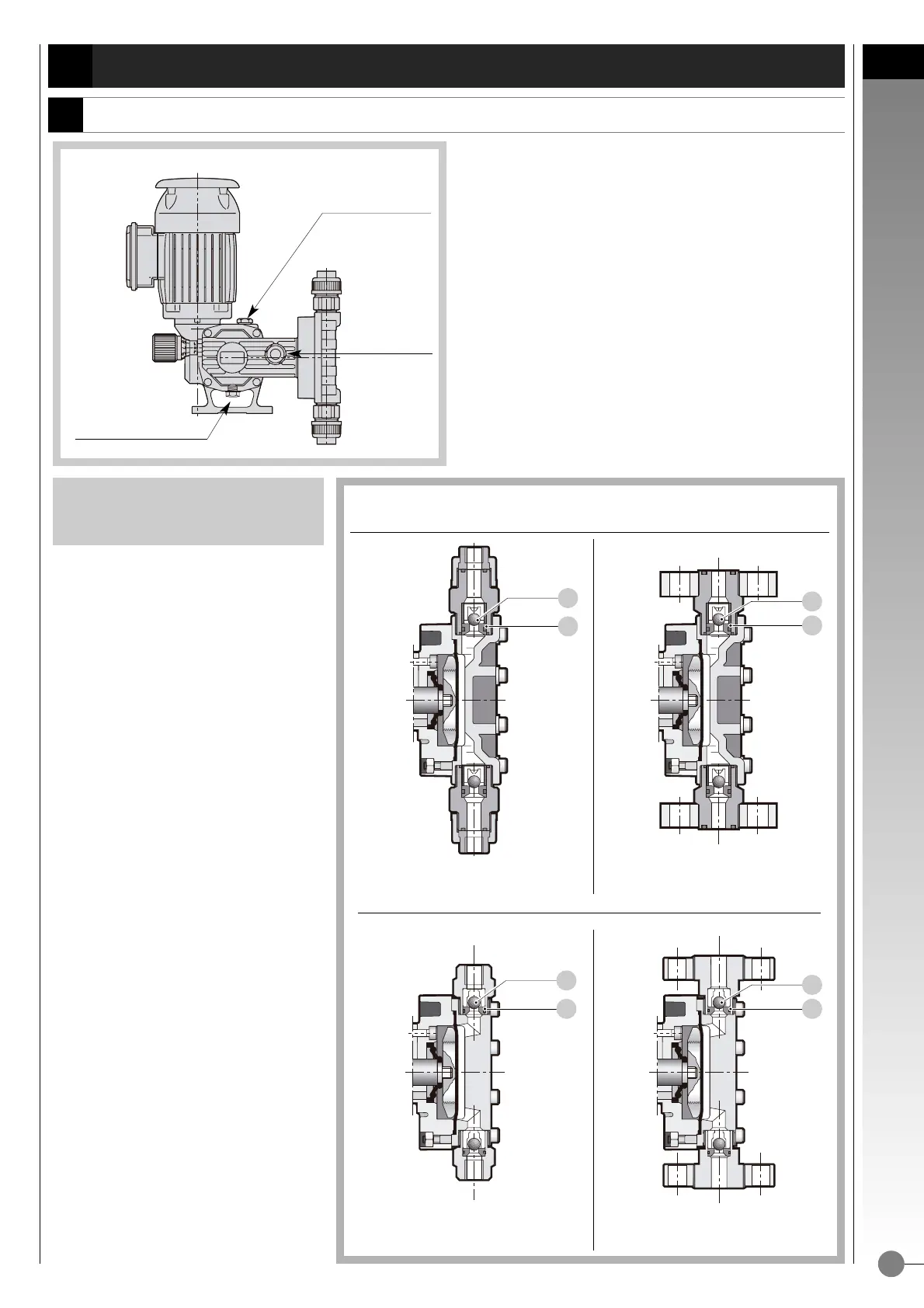

OIL DRAINING

OIL WINDOW

OIL FILLING UP

• Check the oil level periodically

(fig. 16)

.

• Change the oil every 10.000 operating hours.

Loading...

Loading...