2

9

2.6

2.7

Fig. 11

Fig. 12

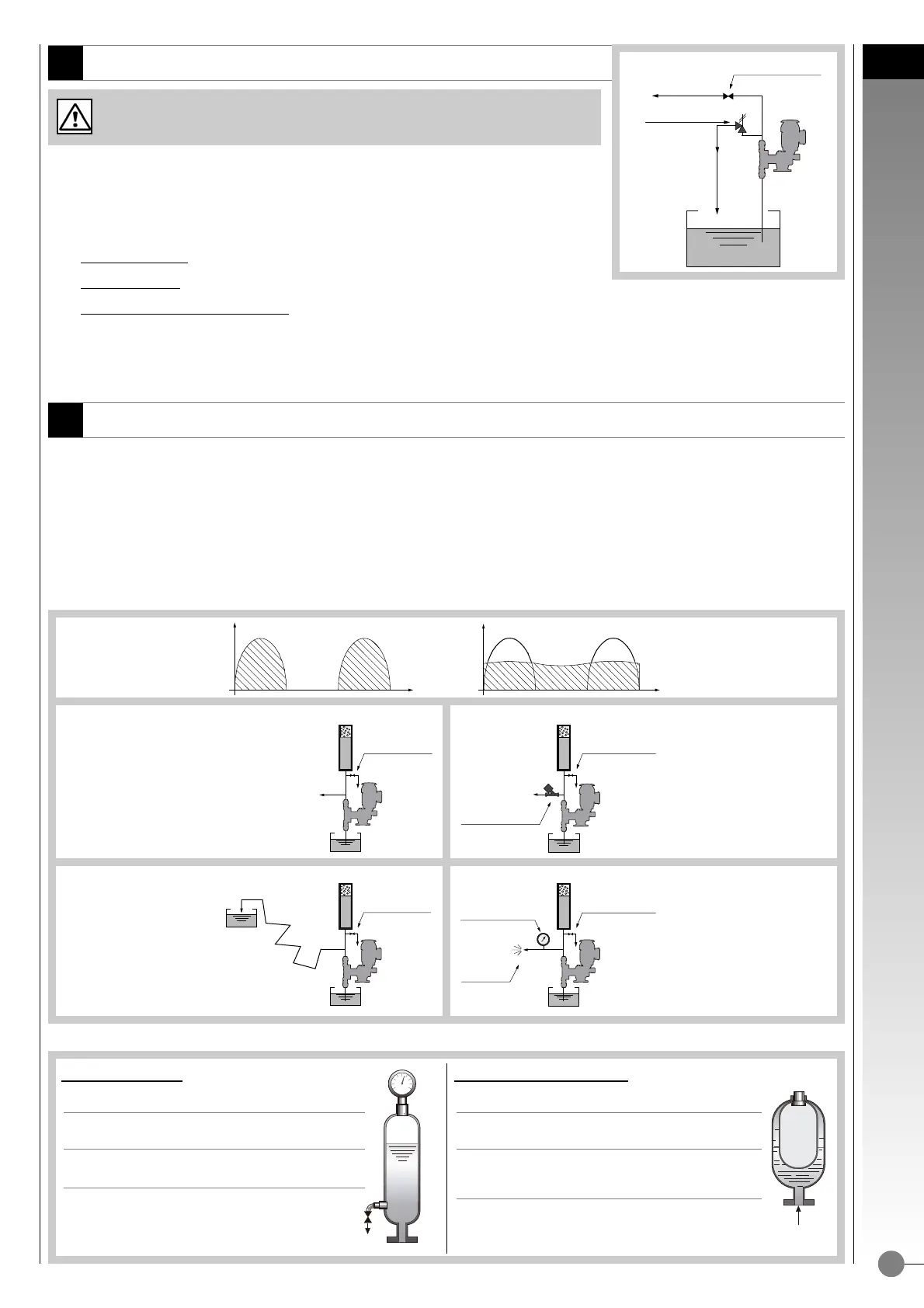

Bladder type dampener

• The liquid is separed from the relieving chamber by a diaphragm.

• Dampener volume: about 8 times the pump swept volume.

Advantages:

• Small volume.

•

No need for periodic inflation because the gas is contained in the bladder.

Disadvantages:

• It is necessary to know prior the exact working pressure in order to

determine the damper precharge.

Dampener types

Bottle dampener

•

Is made up of a cylindrical-shape barrel developed in its height.

• Dampener volume: about 35 times the pump swept volume

.

Advantages:

• It does not need precharge because is self-running.

Disadvantages:

• It has to be regenerated periodically by releasing the liquid

through the drain valve in order to restore the air absorbed by

the liquid.

DAMPENER

DRAIN VALVE

DAMPENER

DRAIN VALVE

SPRAY

NOZZLE

PRESSURE GAUGE

(ABSOLUTELY

NECESSARY)

BACKPRESSURE

VALVE

DAMPENER

DRAIN VALVE

DAMPENER

DRAIN VALVE

Flow rate diaphragm

(with dampener)

Installation with working

pressure lower 1 bar

Spray nozzle

installation

Flow rate diaphragm

(without dampener)

Installation with working

pressure higher than 1 bar

Discharge line too long

and winding

• The pulsation dampener is decisive for a proper operation of the metering pumps.

The installation of a pulsation dampener offers several advantages because this device:

- Protetects the metering pump against pressure peaks, thus increasing the working of life of the pump.

- Prevents vibrations all along the discharge line.

- Smooth the flow, useful for the process.

• The pulsating flow, which is a negative characteristic of all metering pumps, can therefore be prevented by installing a pulsation

dampener on the discharge line (fig. 12).

Examples of installation of the pulsation dampener

INSTALLATION OF THE PULSATION DAMPENER

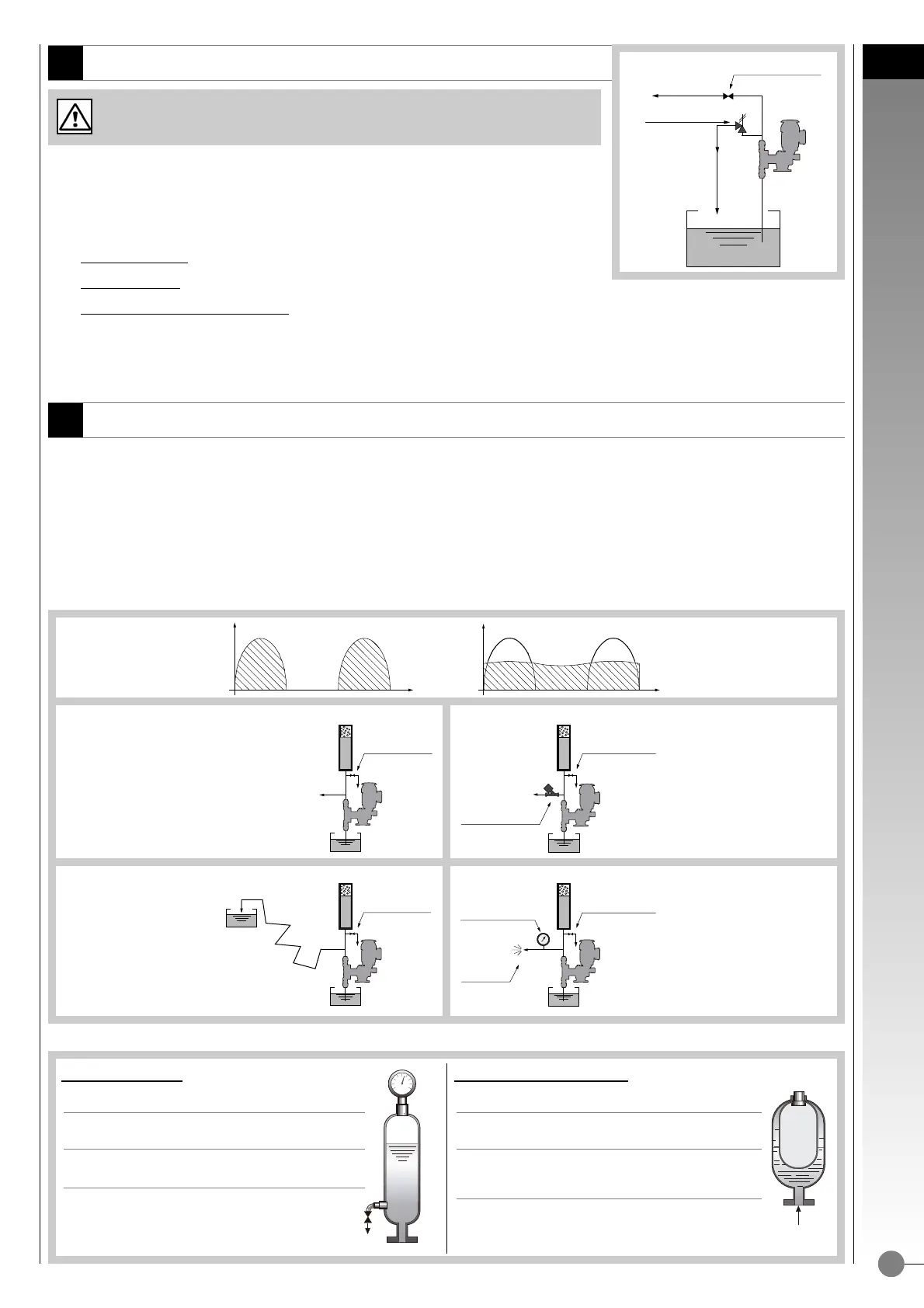

CAUTION ! Mechanical diaphragm metering pumps absolutely need the

installation of a relief valve; a pressure higher than the rating plate value would

break the mechanism.

• The safety valve has to be installed immediately after the discharge connection, anyhow

before the on-off valve.

• The relief valve setting (set pressure) must not exceed the pump max. pressure value.

• The safety valve protects the pump from:

Excessive pr

essure (pressure higher than the rated value).

Operator mistakes (E.G., on-off valve closed on the discharge line when the pump is running).

Obstruction of the dischar

ge piping (reduction in section clogging).

• A relief valve is absolutely necessary when an on-off valve is fitted on the discharge line (fig.11).

The installation of a safety valve is always essential both because of the above reasons and for the safety regulation for accident at work.

SAFETY VALVE

ON OFF VALVE

SAFETY VALVE

INSTALLATION

Loading...

Loading...