20

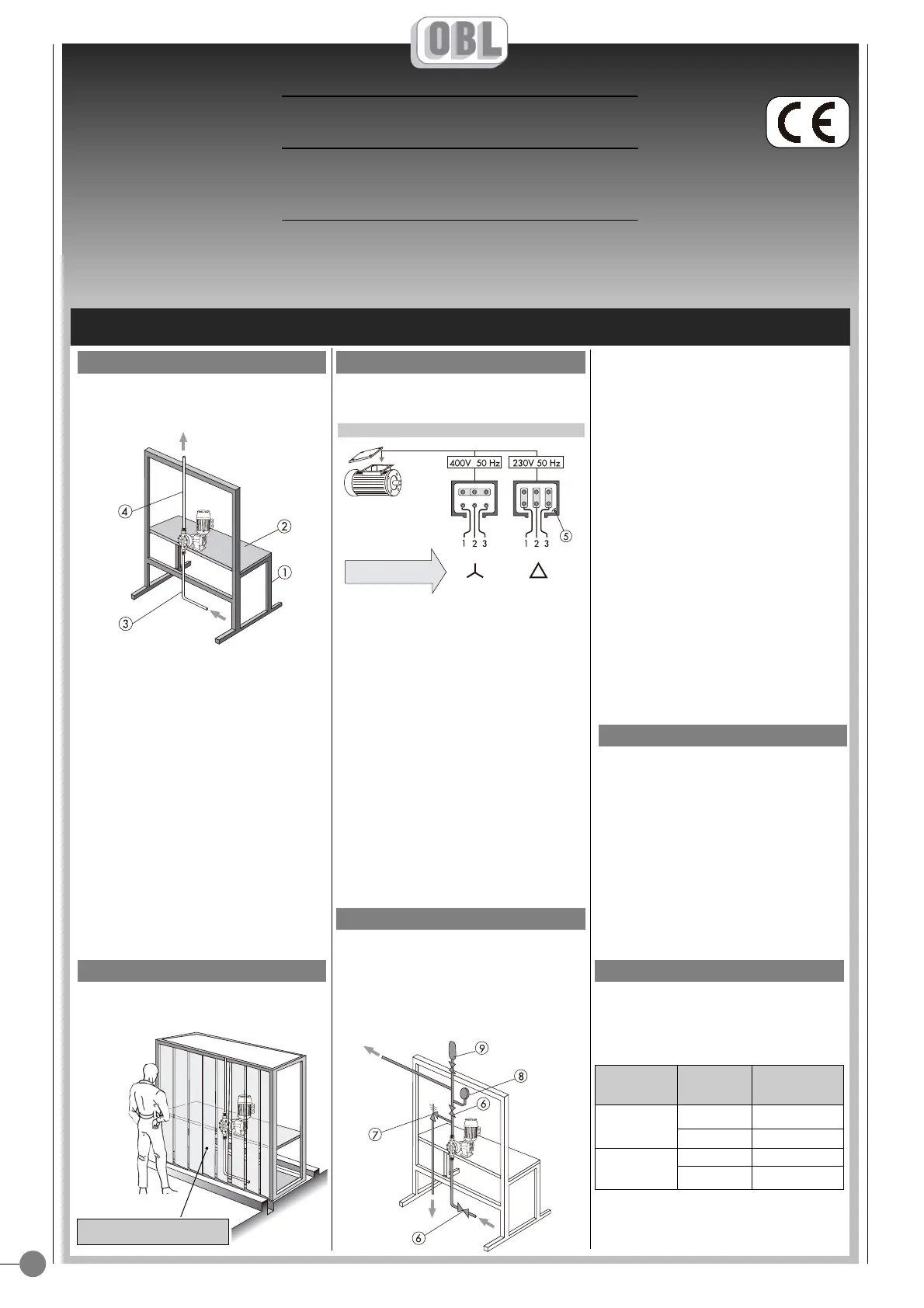

- The pump has to be

installed on a base plate

➀

.

- The basement has to be made of electric

welded steel and fit for the pump dimensions,

with leveled face

➁

.

- The pump has to be strongly fastened to the

basement by clamping screws.

- The basement has to have a frame to sup-

port the suction

➂

and discharge

➃

pipeli-

nes and possible accessories (pulsation dam-

pers, pressure gauges, valves) and not vibrate

while the pump is working.

Protection against accidental leakages

of aggressive pressurized fluids.

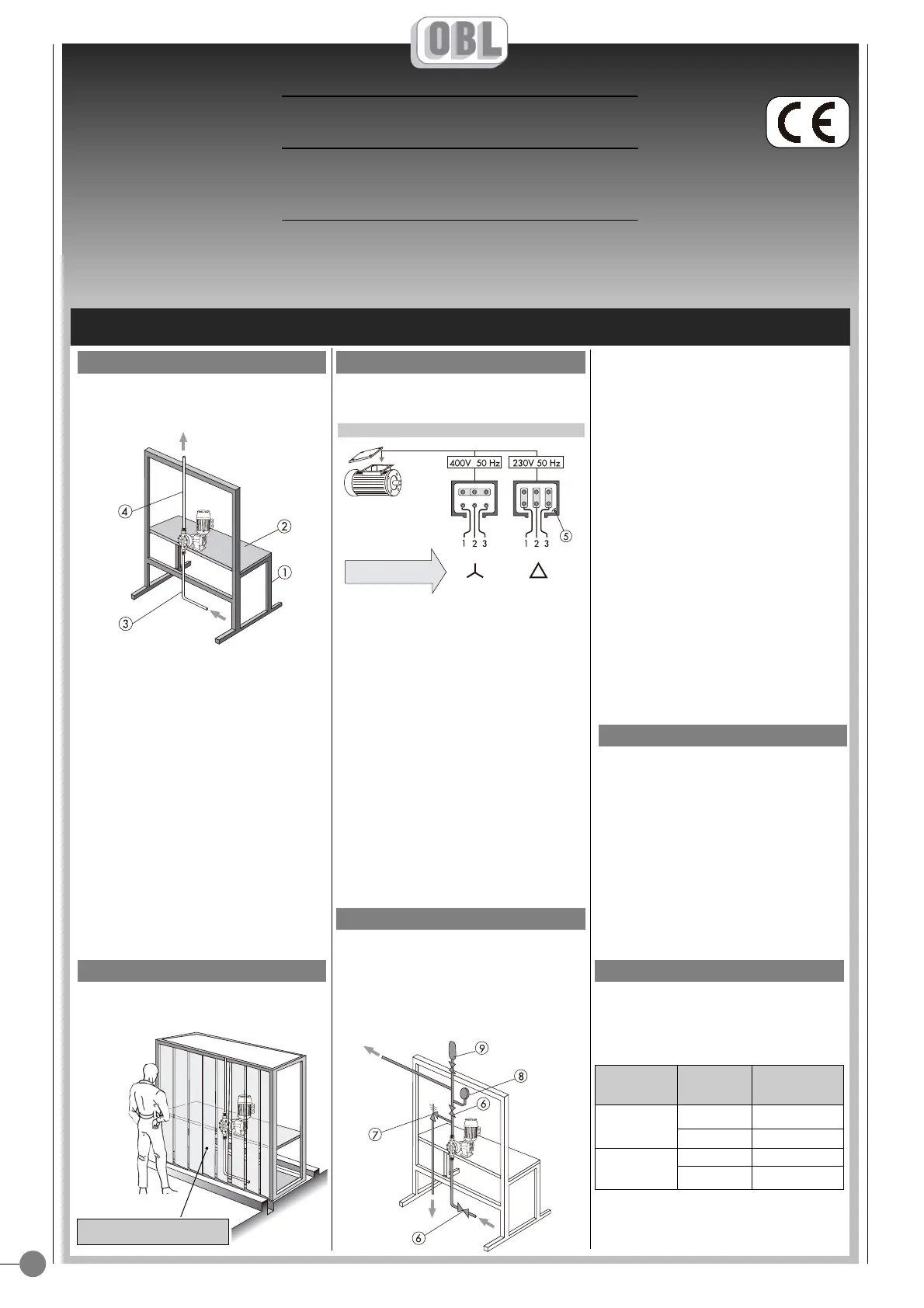

- For a proper connection of the electrical

motor follow the illustrated instructions.

- Protect the motor by installing a magneto-

thermic device, fit to the power input values of

the motor, knowing that the motor, at start,

absorbs at least four times the motor nominal

power.

- Earth the terminal of the motor casing, using

a cable with at least 6 mm

2

section

➄

.

-Check the direction of rotation of the motor

(see the arrow on the motor body); if the

direction of rotation is not in accordance with

the arrow, interchange two wires:

1 on 2, 2 on 1.

WARNING:

Start the motor only when the terminal box

is closed

- Check the oil level.

- Open all the on-off valves both along the

discharge and suction pipeline

➅

.

- Check the relief valve installation and its

discharge into the feeding tank

➆

.

WARNING:

Do not start the pump without a

safety valve.

- Check the pressure gauge installation

➇

(essential to check the pump status).

- Check the pulsation dampener

➈

(essential

for flowrates above 100 L/h).

- Start the pump with adjustment set to 20 %

increase gradually the flowrate (acting on the

adjustment knob) and find the relevant pres-

sure on the pressure gauge.

WARNING:

The working pressure must not exceed the

rating plate value.

- Check during the first three working hours

the pump body temperature (max 40°C) as

well as the motor temperature (max 80°C).

- Check periodically the oil level through the

oil-windows located on the pump body.

First three months, once a month afterwards,

once every four months.

- Check periodically (once every four months)

the pump status:

- Pump body temperature (max 40°C).

- Motor body (max 70°C).

- Working pressure (must not exceed the

rating plate value).

- Noise (within normal conditions must not

exceed 85 dbA).

- In order to avoid damages due to diaph-

ragm breaking it is advisable to replace the

diaphragm according to the pump use as

shown in the table.

- For disassembly and re-assembling see

instructions at page 14.

1 - INSTALLATION

2 - OPERATOR PROTECTION

3 - ELECTRICAL CONNECTIONS

4 - SETTING INTO OPERATION

5 - ROUTINE MAINTENANCE

6 - PREVENTIVE MAINTENANCE

CONTINUOUS

100% 10.000

HOURS

24/24

50% 18.000

HOURS

BATCHING

100% 20.000

HOURS

12/24

50% 30.000

HOURS

REPLACEMENT

ADVISABLE EVERY

WORKING

STATUS

PRESSURE % COMPARED

TO THE MAX PRESSURE

TRASPARENT FLEXIBLE PANELS

PLASTIC MADE (TRASPARENT PVC)

TERMINAL BOX DISPOSAL ACCORDING TO THE LINE VOLTAGE

STAR DELTA

THREEPHASE

ELECTRIC

MOTOR

TIPO DI COLLEGAMENTO

INSTRUCTIONS ABOUT THE RESIDUAL RISKS ELIMINATION AND THE SAFETY AT WORK

METERING PUMPS

MACHINE DIRECTIVE

EUROPEAN COMMUNITY DIRECTIVE 98/37/CE AND SUBSEQUENT MODIFICATIONS

GENERAL SAFETY NORMS

Please read and save these instructions.

Loading...

Loading...