97

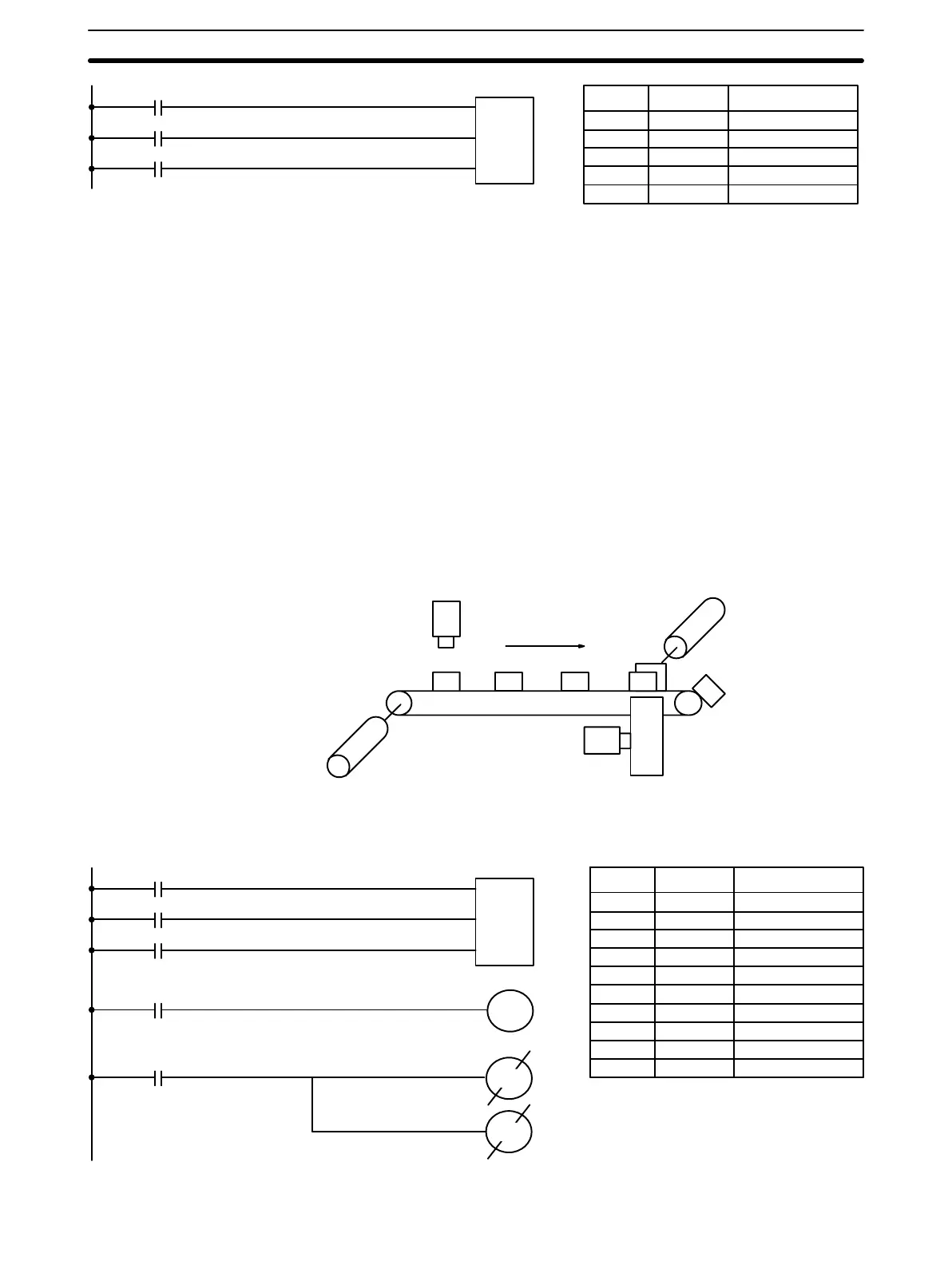

I

P

SFT(33)

DR 10

R

0005

0308

0008

Address Instruction Operands

000 LD 0005

001 LD 0308

002 LD 0008

003 SFT(33)

DR 10

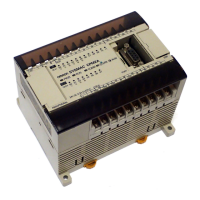

The following program controls the conveyor line shown below so that faulty

products detected at the sensor are pushed down a chute. To do this, the

execution condition determined by inputs from the first sensor (0001) are

stored in a shift register: ON for good products; OFF for faulty ones. Convey-

or speed has been adjusted so that DR 0003 of the shift register can be used

to activate a pusher (0100) when a faulty product reaches it, i.e., when DR

0003 turns ON, 0100 is turned ON to activate the pusher.

The program is set up so that a rotary encoder (0000) controls execution of

SFT(33) through a DIFU(10), the rotary encoder is set up to turn ON and

OFF each time a product passes the first sensor. Another sensor (0002) is

used to detect faulty products in the chute so that the pusher output and DR

0003 of the shift register can be reset as required.

Sensor

Chute

(0002)

(0100)

Sensor

(0001)

Rotary Encoder

(0000)

Pusher

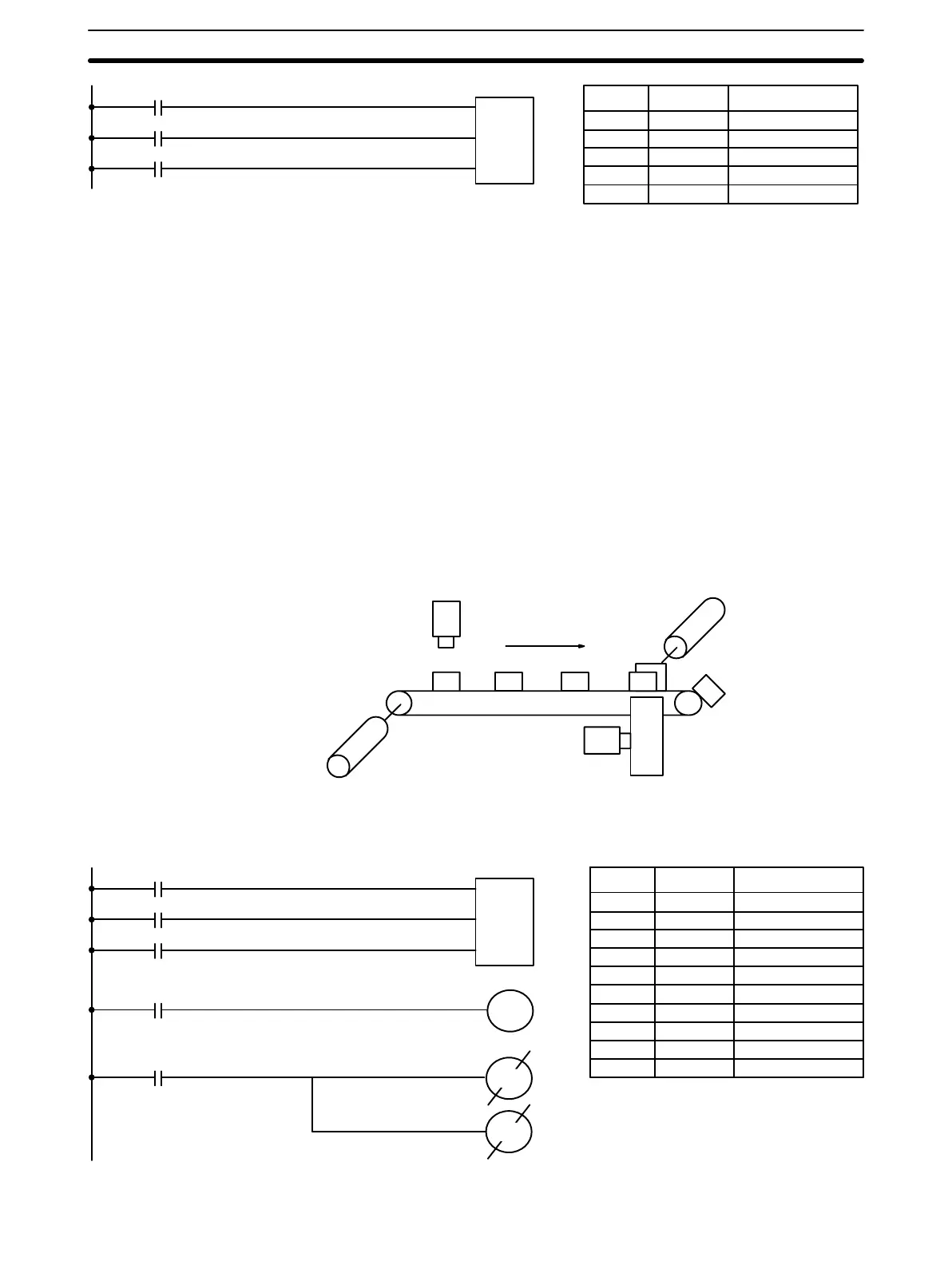

I

P

SFT(33)

DR 00

R

0001

0000

0003

0100

DR 0003

0002

DR 0003

0100

Address Instruction Operands

000 LD 0001

001 LD 0000

002 LD 0003

003 SFT(33)

DR 00

004 LD DR 0003

005 OUT 0100

006 LD 0002

007 OUT NOT 0100

008 OUT NOT DR 0003

Example 2:

Control Action

Instruction Set Section 3-7

Loading...

Loading...