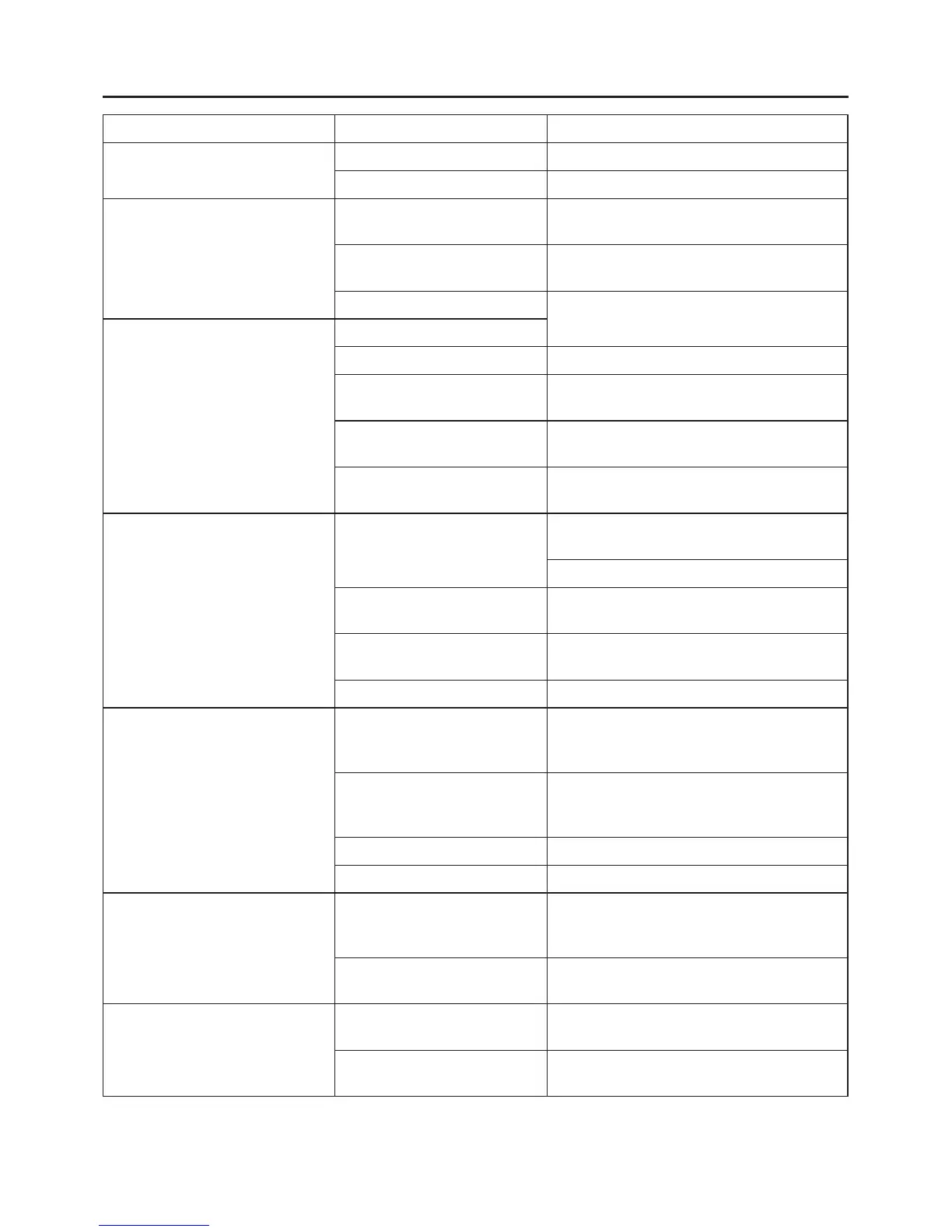

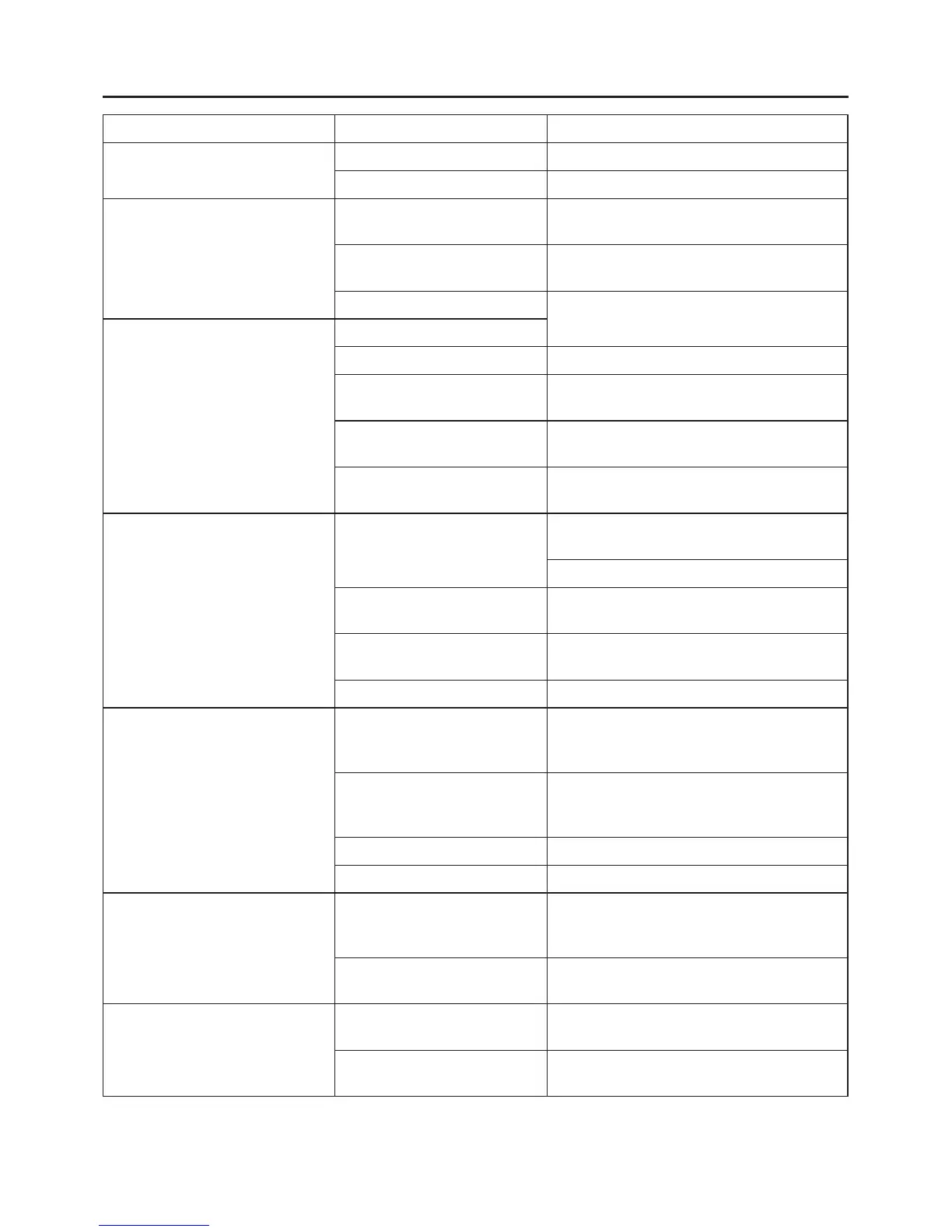

Troubleshooting* 19

Fault Possible Causes Solution

Over Current

Shorted output Check for any shorts in motor cables.

Damaged wire insulation Check motor wire insulation with a megger.

Over Voltage

Internal Drive short

With power to Drive off, measure outputs

with ohmmeter to detect short.

Power cycling on and off

Check for a generator or switching on input

line.

High line voltage

MeasureincominglinevoltagetoDrive;

should be between 190V and 265V.

Under Voltage

Low line voltage

Temporary loss of power Check for local power outage.

Excessive load current

Check motor is correctly sized for the

application.

Loss of a motor phase

Check correct voltage is present on all motor

leads.

Power was removed from

Drive

Check correct voltage is present on all input

lines.

Cannot Start Motor

Exceeding Service Factor Amps

Check Service Factor Amps entered are

correct.

Check pump and motor are correct.

No Service Factor Amps value

entered

Check Service Factor Amps entered and are

correct.

There is an open (connection)

in motor wires

Check resistance of all motor wires is

correct.

Locked rotor Pull pump check for debris in pump.

Dry Run

Operation at open discharge

MayneedtoreduceDry Run Sensitivity

pressure or apply back pressure on

transducer.

Drive cannot read transducer

signal

Check linearity of transducer, as it may be

damaged. See Troubleshooting Guide for

more information.

Possible leak Check for pipe break or large leak.

Dry running pump Check water level in well.

Ground Fault

Ground wire shorted to motor

phase

Check the ground wire for short to motor

phase wire or check insulation integrity with

a megger.

Long motor cable length

Motorcablelengthmorethan1000ftisnot

recommended.

System Not Grounded

Ungrounded Drive

Ground Detect parameter can be disabled,

but will reactivate after 72 hours.

Unbalanced or three phase

incoming voltage.

Line to line voltage must be twice line to

ground voltage.

Loading...

Loading...