ELECTRICAL

5.7

CHARGING SYSTEM TESTING

CAUTION: Do not connect or disconnect the battery cable or ammeter with the engine running.

CAUTION: Never use the electric starter with the ammeter connected, or damage to the meter or meter fuse may

result. Do not run test for extended period of time. Do not run test with high amperage accessories.

The “break even” point of the charging system is the point at which the alternator overcomes all system loads

(lights, etc.) and begins to charge the battery. Depending on battery condition and system load, the break even

point may vary slightly. The battery should be fully charged before performing this test.

SConnect an ammeter (set to DC amps) in series be-

tween the negative battery cable and terminal.

SConnect a tachometer according to manufacturer’s in-

structions.

SWith engine off and the key and kill switch in the ON

position, the ammeter should read negative amps

(battery discharge). Reverse meter leads if a positive

reading is indicated.

SElevate machine so rear wheels are off the ground.

Start engine with recoil

only.

SIncrease engine RPM while observing ammeter and

tachometer.

SNote RPM at which the battery starts to charge (am-

meter indication is positive).

SThis should occur at approximately 1500 RPM or low-

er.

SLock parking brake to keep brake light on.

SRepeat test, observing ammeter and tachometer.

With lights on, charging should occur at or below 2000

RPM.

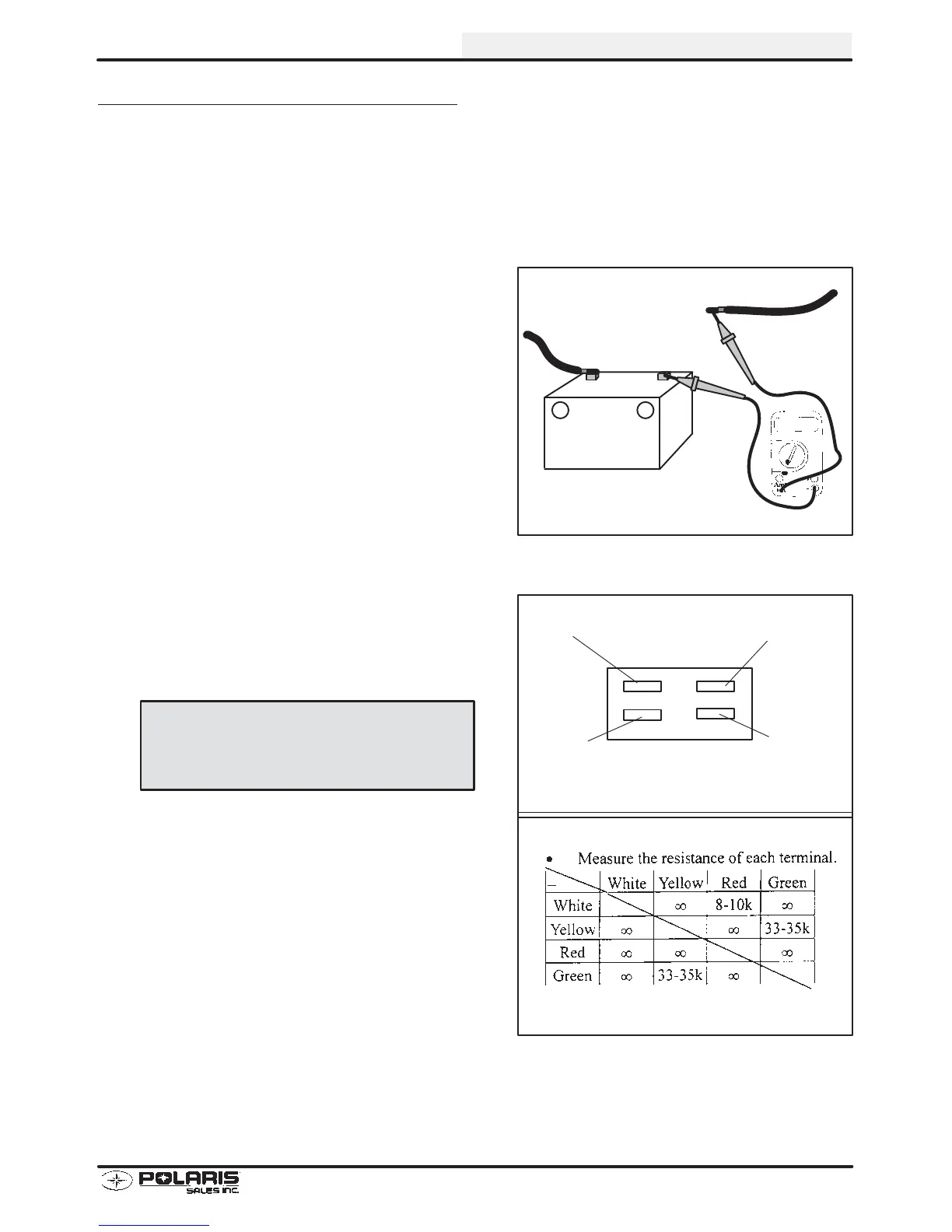

2. If the values do not meet the requirements, inspect the

regulator/rectifier. Measure the resistance of each

terminal and compare to chart at right. If any readings

are different than shown, replace regulator/rectifier.

Do not use electric start.

–+

Current Drain Inspection

Key Off

Less Than 9 mA

Red

White

Yellow

Green

Regulator Rectifier

Voltage: 13.5-15.5 V

Amperage: 1.0 A under 5000 RPM

Loading...

Loading...