ENGINE

2.13

ENGINE INSPECTION PROCEDURES

Cylinder Head Inspection

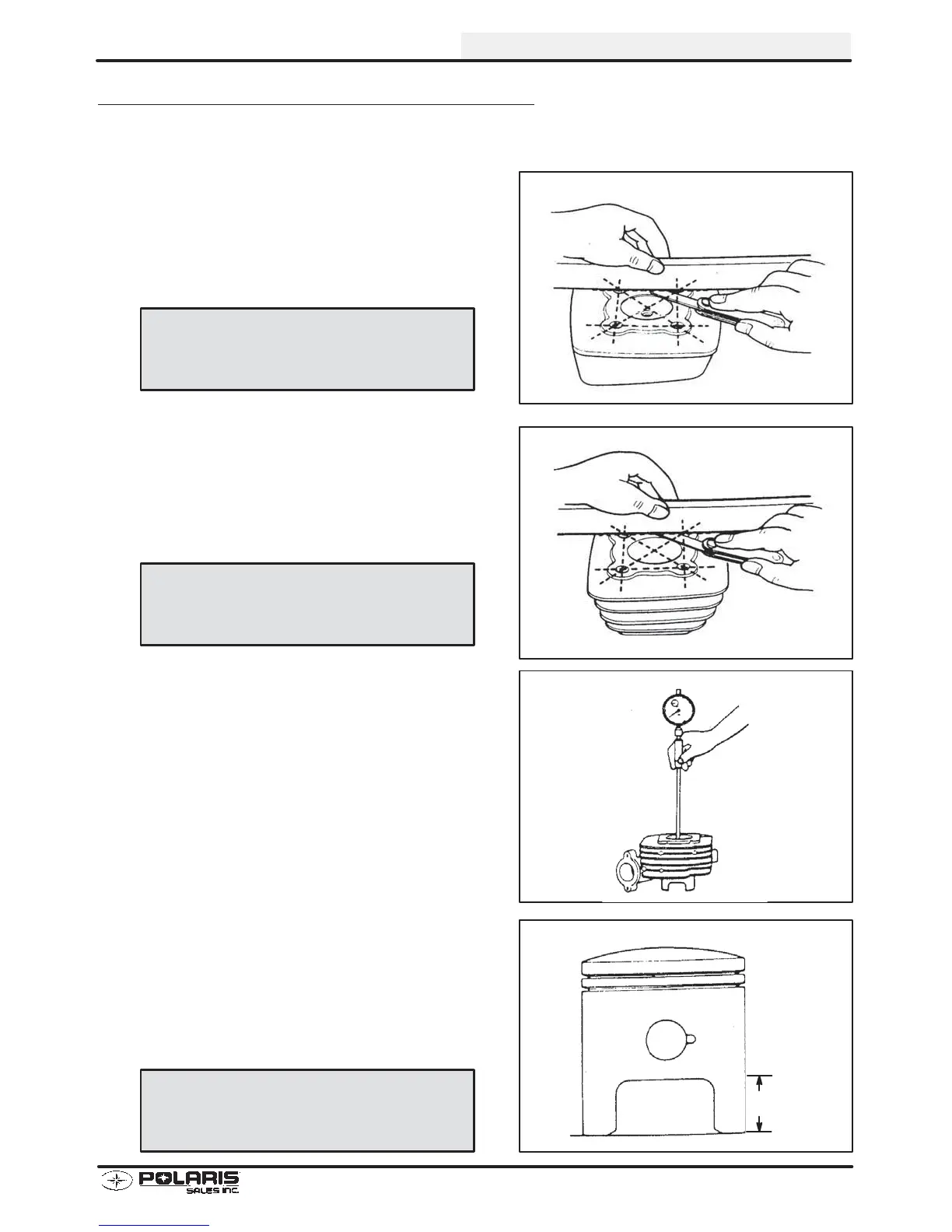

1. Inspect the surface of the cylinder head for

warpage. Clean all gasket residue completely from

sealing surface. Use a feeler gauge and straight

edge. Measure the gap six(6) different ways as

shown in illustration at left. Normal gap should be

.002

″

(0.05 mm) or less. If gap is excessive,

resurfacing head or replacement is needed.

Cylinder Inspection

2. Inspect the surface of the cylinder for warpage.

Clean all gasket residue completely from sealing

surface. Use a feeler gauge and straight edge.

Measure the gap six(6) different ways as shown in

illustration at left. Normal gap should be .002″ (0.05

mm) or less. If gap is excessive, resurfacing

cylinder or replacement is needed.

3. Inspect the cylinder walls for damage or scoring.

The cylinder bore must be de-glazed whenever new

piston rings are installed. If cylinder wear or

damage is excessive, it will be necessary to

oversize the cylinder using a new oversize piston

and rings. See Honing to Oversize in this chapter.

Inspect cylinder for out of round.

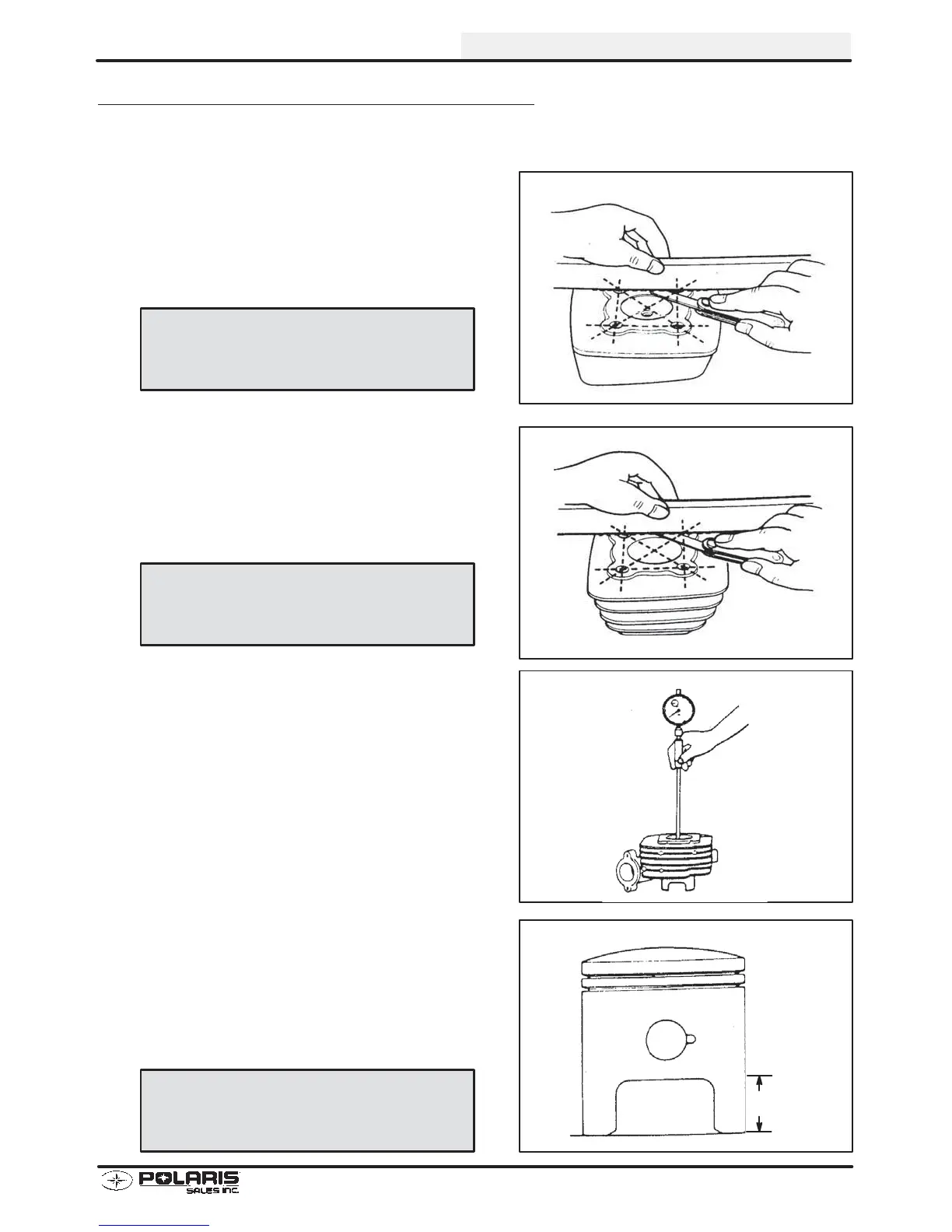

PIston Inspection

4. Inspect the piston for scoring or cracks in piston crown

or pin area. Excessive carbon buildup below the ring

land is an indication of piston, ring, or cylinder wear. If

damage is excessive, replace piston. Piston-to-cylinder

clearance should not exceed .0047″ (0.12 mm).

Measure the piston 5/8″ (15 mm) from bottom. Then

measure inside diameter of cylinder. The difference

between these measurements should not exceed

.0047″ (0.12 mm).

Cylinder Head Warp

Service Limit:

.002I (0.05 mm)

Cylinder Warp

Service Limit:

.002I (0.05 mm)

5/8″ (15 mm)

Piston to Cylinder Clearance:

.0047I (0.12 mm)

Loading...

Loading...