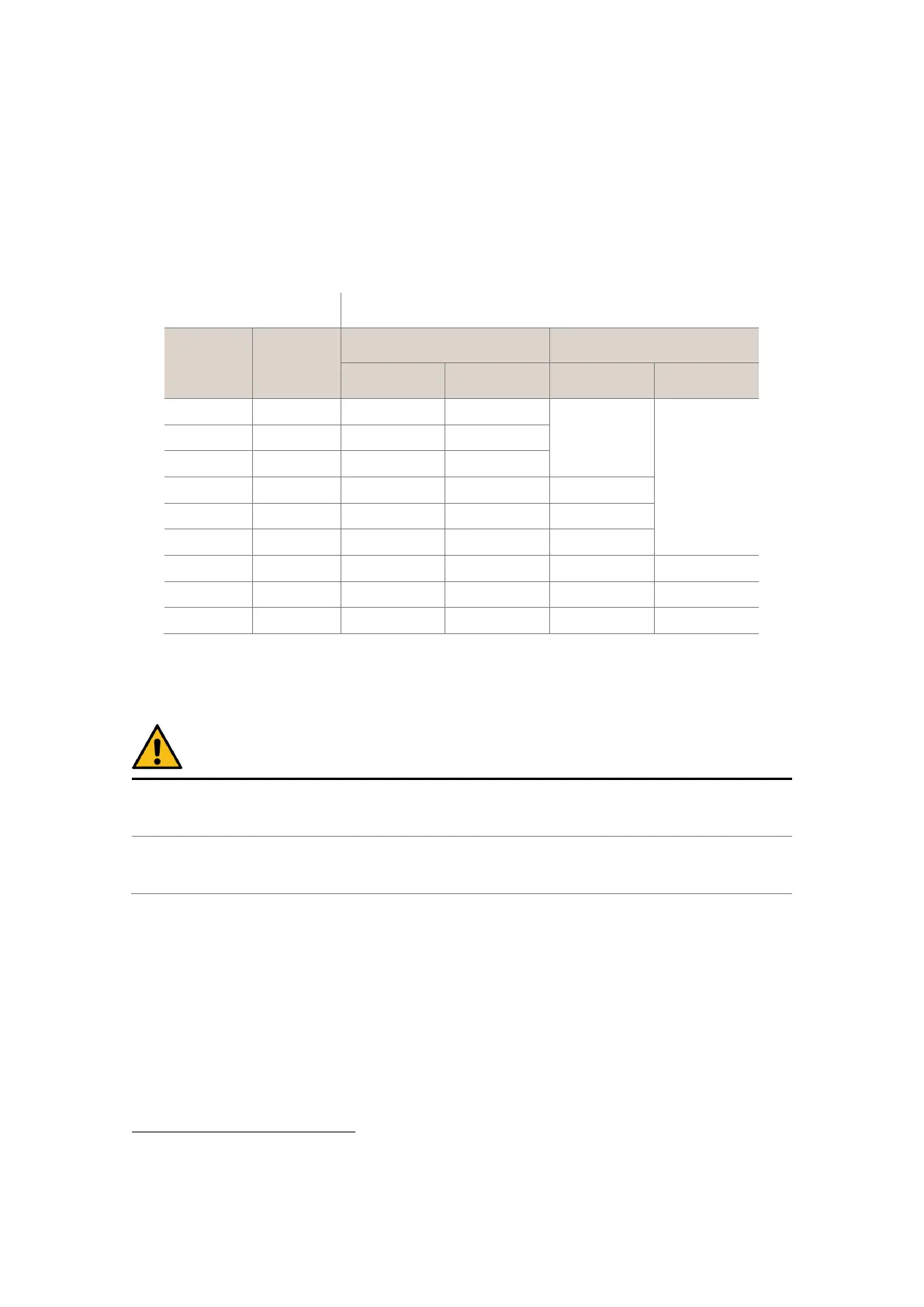

TORQUE AND SCREW SIZING

The following table shows, broadly speaking, the recommended torque for both mechanical and electrical

connections, applicable to all cabinets

[

[a] For other qualities, follow the screw’s manufacturer guidelines.

For all screwing that holds a particular component such as a bus, contactor, etc. it will be necessary to

apply the tightening torque indicated by the manufacturer of the same component

Screwing should be tightened correctly only when necessary, i.e. when the factory marks are not in place.

For small screws that do not have marks, the good electrical praxis will determine if it is loose.

Power Electronics recommends the use of Zinc Steel quality 8.8 bolts for internal connections in general, DC and

earth connections included.

Power Electronics recommends the use of A2-70 stainless bolts for external connections in general, AC connections

included.

Loading...

Loading...