2

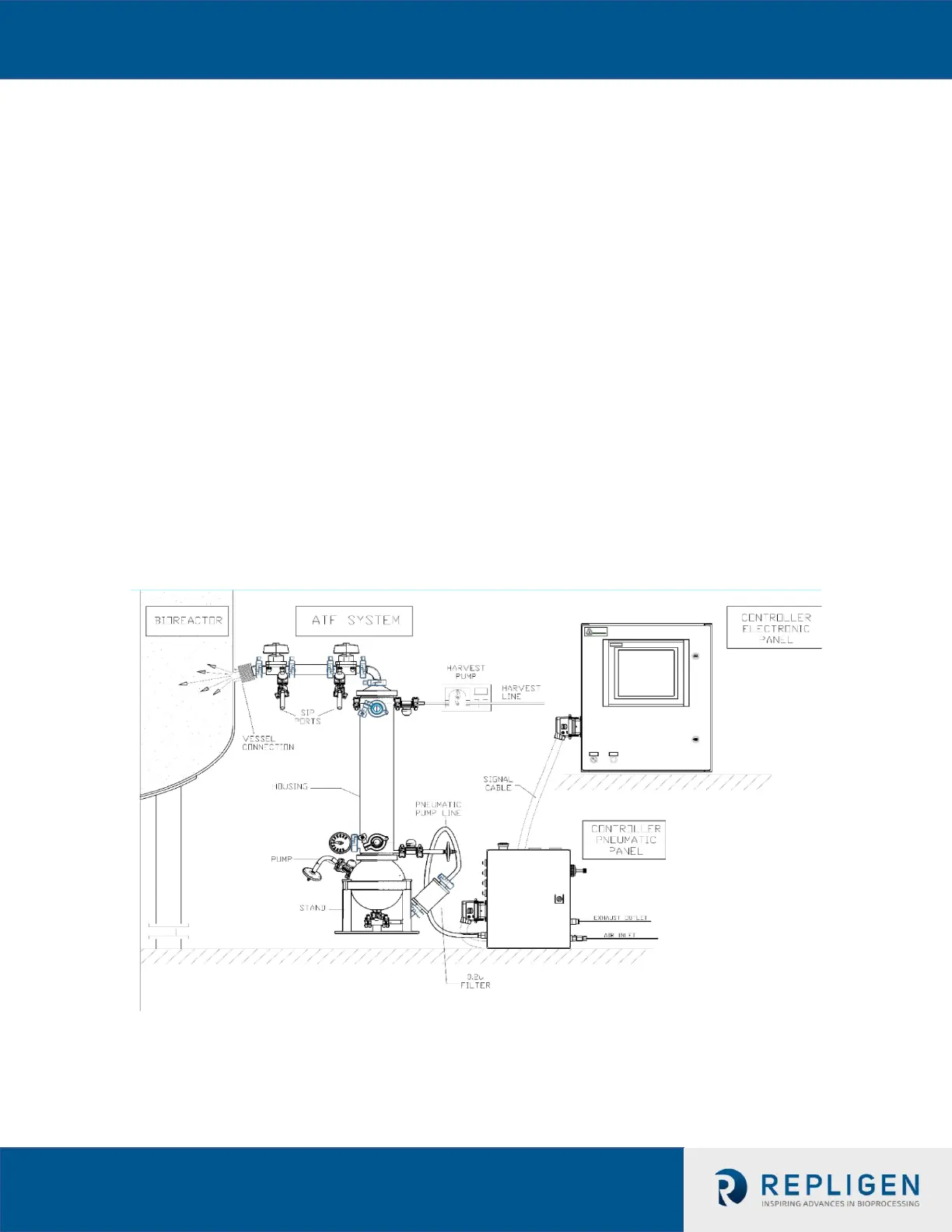

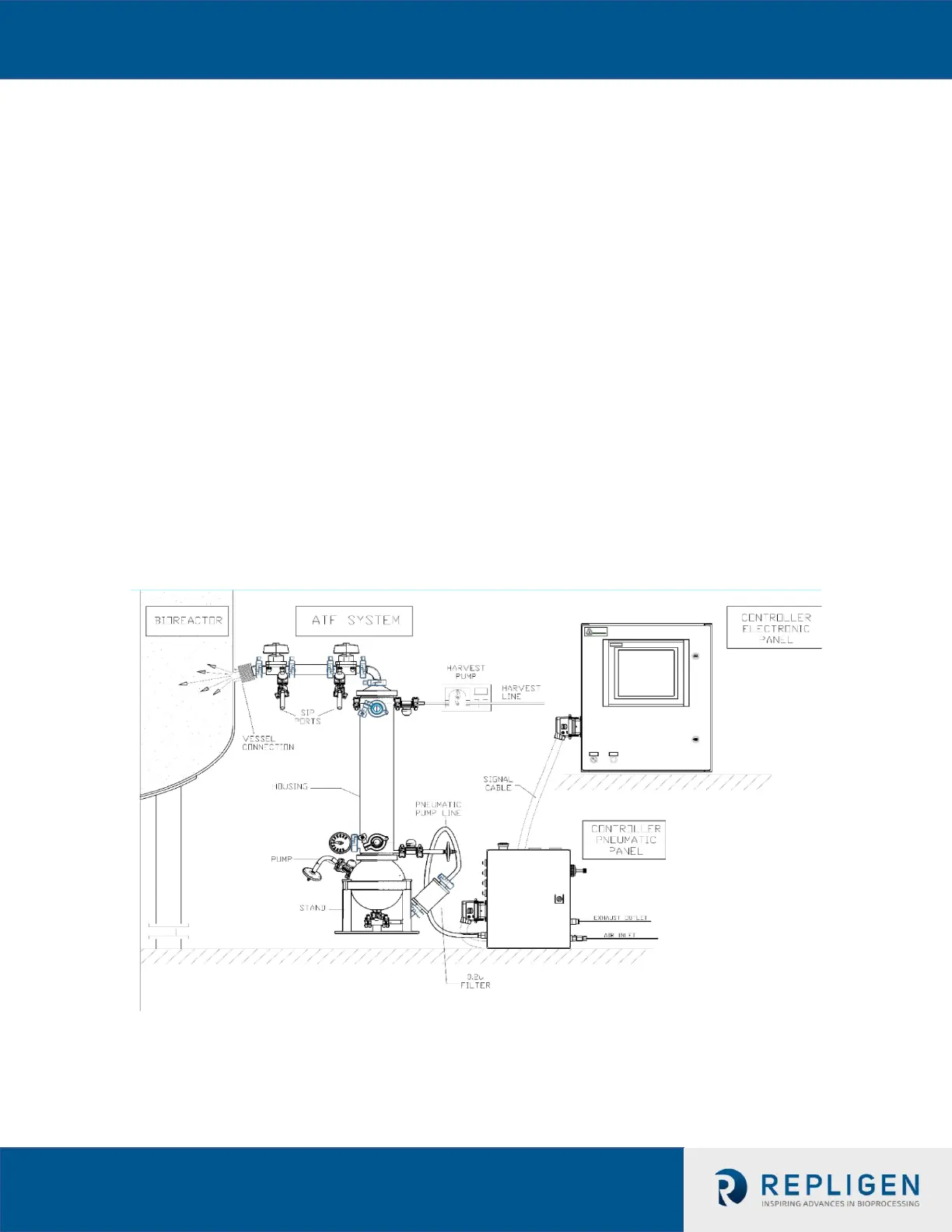

A typical configuration of the XCell™ ATF System is shown in Figure 1. The Filter Housing accepts

either HFM, with pore sizes from 750kD to ~0.2 micron, or a SM for fractionation of larger

particles, >70 microns. The separating element, the HFM or SM, is positioned between a process

vessel or a bioreactor at one end and the Diaphragm Pump at the other end. The vessel serves as

a storage container for the content to be filtered. The Diaphragm Pump provides the means for

generating alternating tangential flow (ATF), moving the contents of the vessel back and forth,

between the vessel and pump, through the hollow fibers of the HFM or through the SM. The

XCell™ ATF process provides the means for generating rapid, low shear, tangential flow, allowing

for retention of the larger components (i.e.- cells) and filtration of smaller components (i.e. –

media components).

A filtrate pump as shown in Figure 1 is used for controlled removal of a filtered stream. The

unfiltered material remains in the system. Only a single connection is required between the

XCell™ ATF System and the vessel. As shown in Figure 1, the connection can be through a side

port (or bottom port) commonly configured on large scale stainless steel or single-use

bioreactors, or through the head plate as typical with smaller bioreactors. When placed next to

the vessel, only a short connection, commonly referred to as the A2B Connection, is required

between the XCell™ ATF system and the vessel. This connection can be hard piped or soft piped

and is made in a sterile manner. The filtration process remains closed and therefore sterility

between the vessel and the XCell™ ATF System is maintained.

Figure 1. Filtration Assembly Connection to C410v4B Controller and a Bioreactor Side Port

Note: The XCell™ ATF C410v4B Controller has one additional enclosure, the power box (P-box)

which houses the high voltage electrical components (not displayed here). Please reference the

XCell™ ATF Single-use Start up Guide for proper single-use connectivity.

Loading...

Loading...