Warning

Please Note

The specifications of the product detailed on this

Set-Up Guide may change without notice. RDM

Ltd. shall not be liable for errors or for incidental

or consequential damages, directly and indirectly,

in connection with the furnishing, performance or

misuse of this product or document.

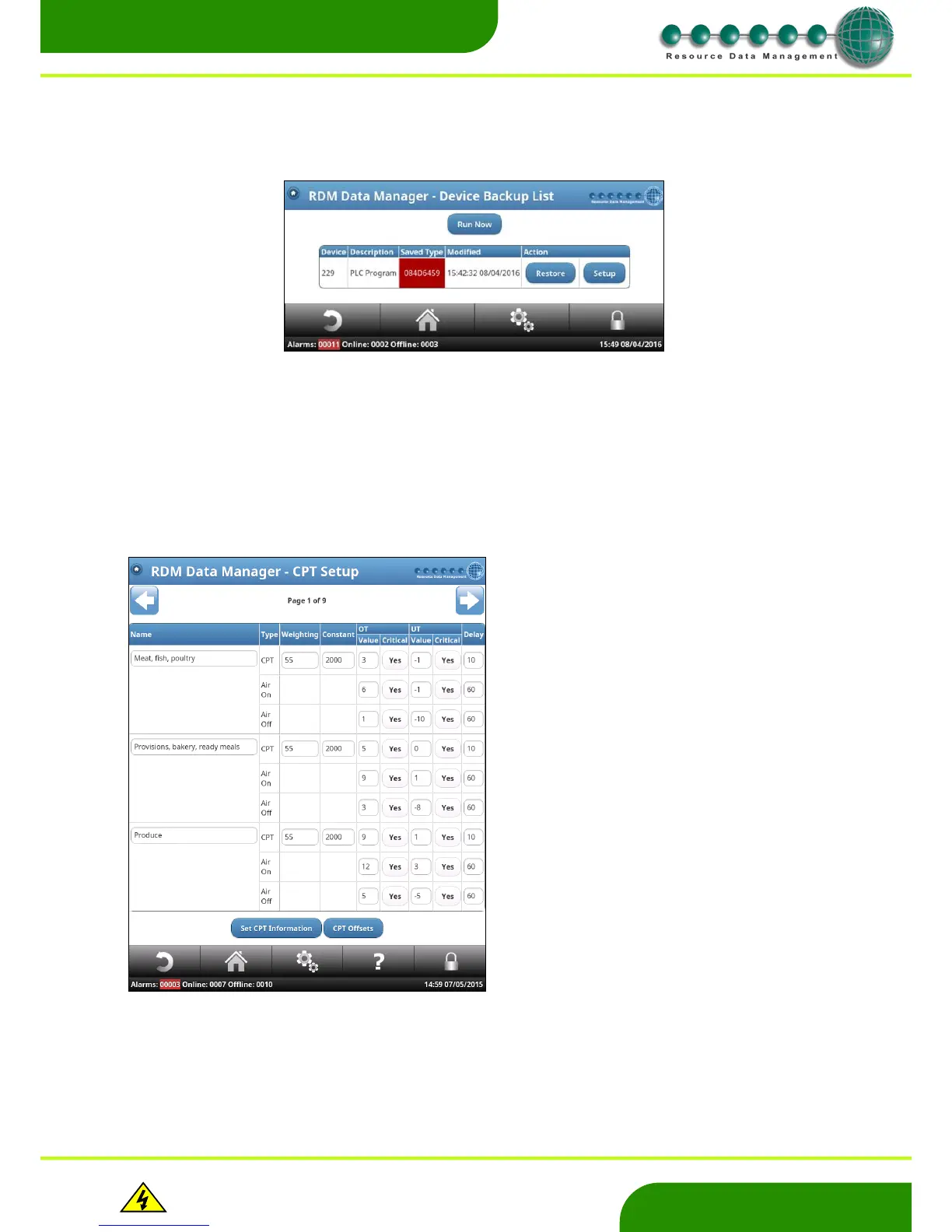

If the TDB program requires a read password, enter it here, if not ensure the field is left blank. Once entered, click ‘save’. The result will

show the main Device Backup list again. Click on ‘Run Now’ to perform the backup so the current TDB program is saved. The type and

modified date details will now be filled in.

If the TDB program has been changed and as a result, differs from the saved TDB program, the DMTouch will highlight the type field in

red;

In the example where the current type (TDB program) differs from the saved version, the user has the option to start the setup process

again and save the ‘altered’ program as the new Backup. Or the option to ‘Restore’ will be available. Clicking this option will prompt the

user for a ‘Write’ password before overwriting the TDB program on the device. Note – use with caution, as restoring the program will

overwrite all previous changes.

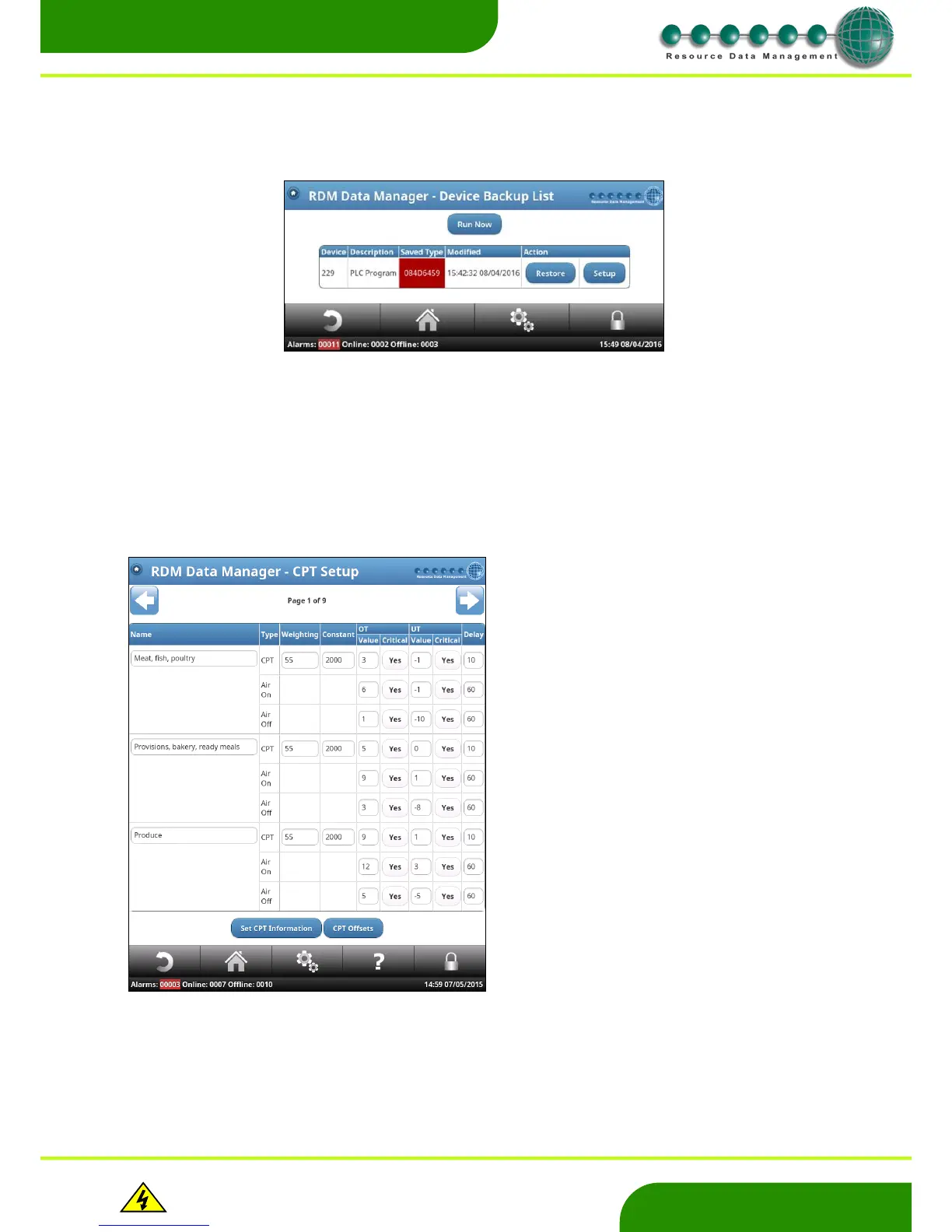

CPT Setup – (Calculated Product Temperature)

From the Service Tab select: Service – Devices – CPT Setup

Allows the user to configure and adjust the factors used to calculate the various CPT product options.

Name Enter a description for the desired CPT

product type.

Weighting Percentage of the Air-On temperature that

is used to calculate the CPT. The remaining percentage will be

Air-Off temperature. Example, a weighting of 30% would result

in CPT = 30% Air-on + 70% Air-off.

Constant The value used in the CPT calculation to

generate CPT’s for varying product types such as Meat, Fish,

Dairy etc.*

OT/UT Value The Over Temperature or Under

Temperature alarm limit assigned to a CPT product. Note an

OT or UT alarm event can be triggered from either the CPT

value or the Air On probe or the Air Off probe temperature.

Setting the limit to 99 or -99 will disable the alarm for that

temperature source.

OT/UT Critical CPT alarms which are set as non-critical

generate alarms with the text “Non Critical” in the alarm

message.

Delay The alarm delay applied to an OT and UT

alarm for a given CPT product.

*For further information on CPT please contact RDM Technical

Support. The sample screen shot above shows the factory

default settings.

Loading...

Loading...