WORKSHOP MANUAL

Map of functional units

TC 108 SD - TC 118 SD

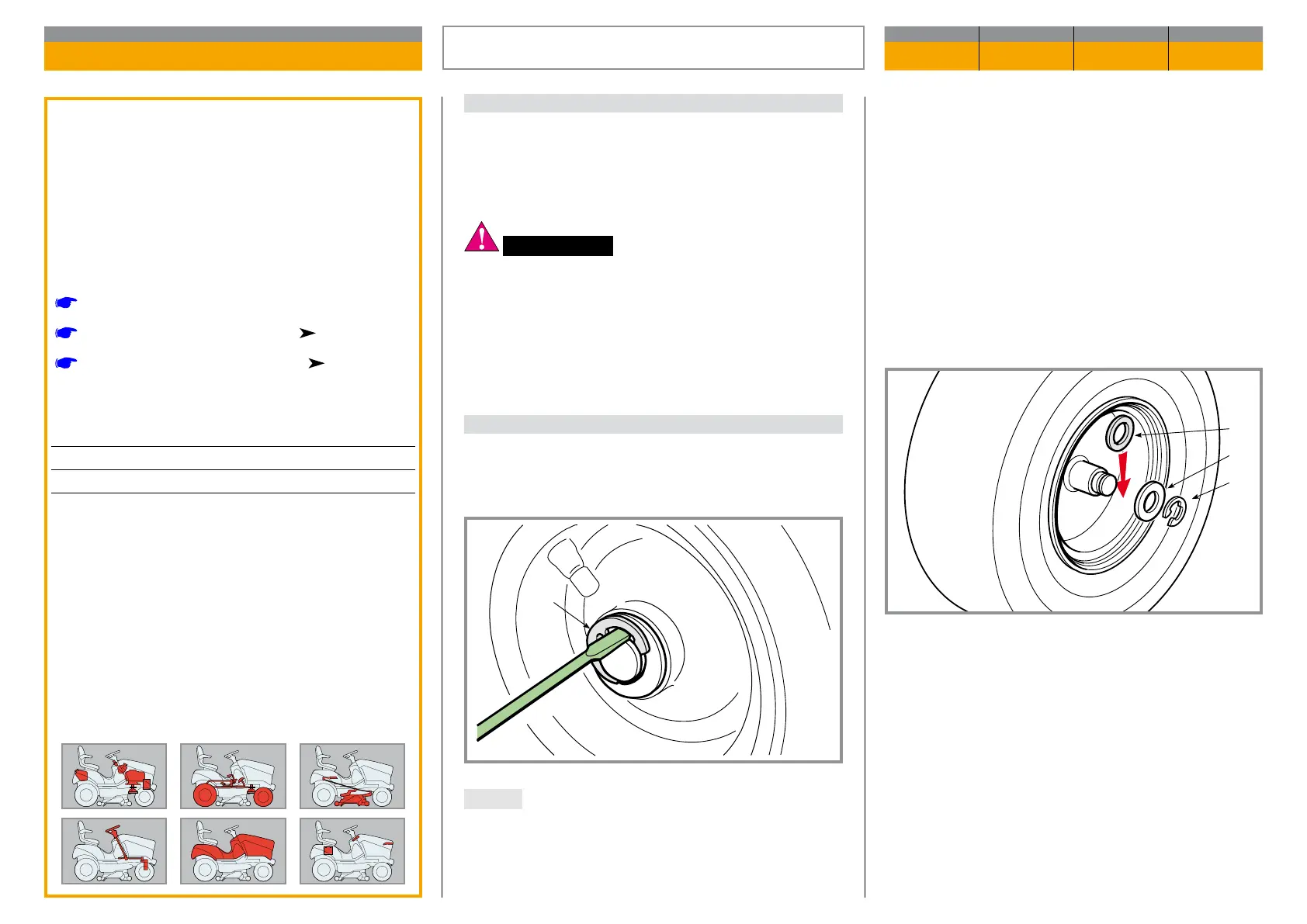

On assembly it is advisable to spread grease on the

shaft to facilitate the next wheel removal.

● For the front wheels: replace the shoulder washer

(2) and the exible ring (1) with the bevel facing in-

wards.

● For the rear wheels: replace the shoulder washer

(2) and the exible ring (1) with the bevel facing in-

wards and check the axial gap of the wheel on the

shaft; if it is greater than 3 mm, a spacer (3) must be

tted between the wheel hub and the shoulder wa-

sher (2).

A) Tyres

After replacing one or more tyres or the wheels, it is

al ways necessary to check the pressure and to check

the alignment of the cutting deck.

ATTENZIONE Replace distorted wheel rims

as they could impair the tyre’s hold.

B) Wheels

The wheels are held by a snap ring (1) which can be

removed with the help of a screwdriver.

NOTE If a wheel is jammed onto the shaft, use a

releasing spray, directing it around the splining hole.

General informations

The tyres used are of the “Tubeless” type and so

e ve ry repair of a hole in the tyre must be done by

a ty re specialist according to the methods used

for this type of tyre.

Related topics

[

2.3] Lifting of the machine

[

4.5] Aligning the cutting deck ( TC 108 SD)

[

4.5a] Aligning the cutting deck ( TC 118 SD)

Tyre pressures

Front ......................................................... 1,0 Bar

Rear .......................................................... 1,4 Bar

REPLACEMENT OF TYRES AND WHEELS

CHAPTER REVISION FROM ... PAGE

6.1 0 2018 1 of 1

Loading...

Loading...