If this pressure remains constant,

the carburetor is airtight. However,

if it drops, there are two possible

causes:

1. The inlet needle is not sealing

(foreign matter in valve seat or

sealing cone of inlet needle is

damaged or inlet control lever

sticking).

2. The metering diaphragm is

damaged.

In either case the carburetor must

be removed and serviced - see

"Carburetor" handbook.

- After completing test, open the

vent screw and pull the fuel hose

off the elbow connector.

- Install the carburetor -see 8.2.1.

FS 400/450, FR 450

- Push the fuel hose onto the

elbow connector.

- Fit the shroud -see 4.1.

Standard setting

If the carburetor has to be

adjusted from scratch, first carry

out the standard setting.

- Carefully screw in both adjusting

screws clockwise until they are

hard against their seats.

Now make the following adjust-

ments:

H= Open high speed screw (1)

one full turn

L

= Open low speed screw (2)

one full turn

A slight correction to this setting

may be necessary at high altitudes

(mountains) or near sea level. Use

the following procedure:

- Mount approved cutting tool.

- Check the air filter, replace if

necessary.

- Check spark arresting screen,

clean or replace as necessary.

- Start the engine and allow it to

warm up.

Turn high speed screw(H)

clockwise for leaner mixture at

high altutude,

or counterclockwise for richer

mixture at sea level.

Turn screw slowly and carefully –

slight changes have a noticeable

effect on engine running behavior.

Adjusting idle speed

Engine stops while idling:

- Carry out standard setting.

Turn the idle speed screw(LA)

clockwise until cutting tool begins

to rotate, and then turn screw back

one half turn.

Turn the idle speed screw(LD)

clockwise until engine runs

smoothly – cutting tool must not

rotate.

Cutting tool rotates while

engine is idling:

- Carry out standard setting.

Turn the idle speed screw(LA)

counterclockwise until cutting tool

stops rotating – and then turn it

about another one full turn in the

same direction.

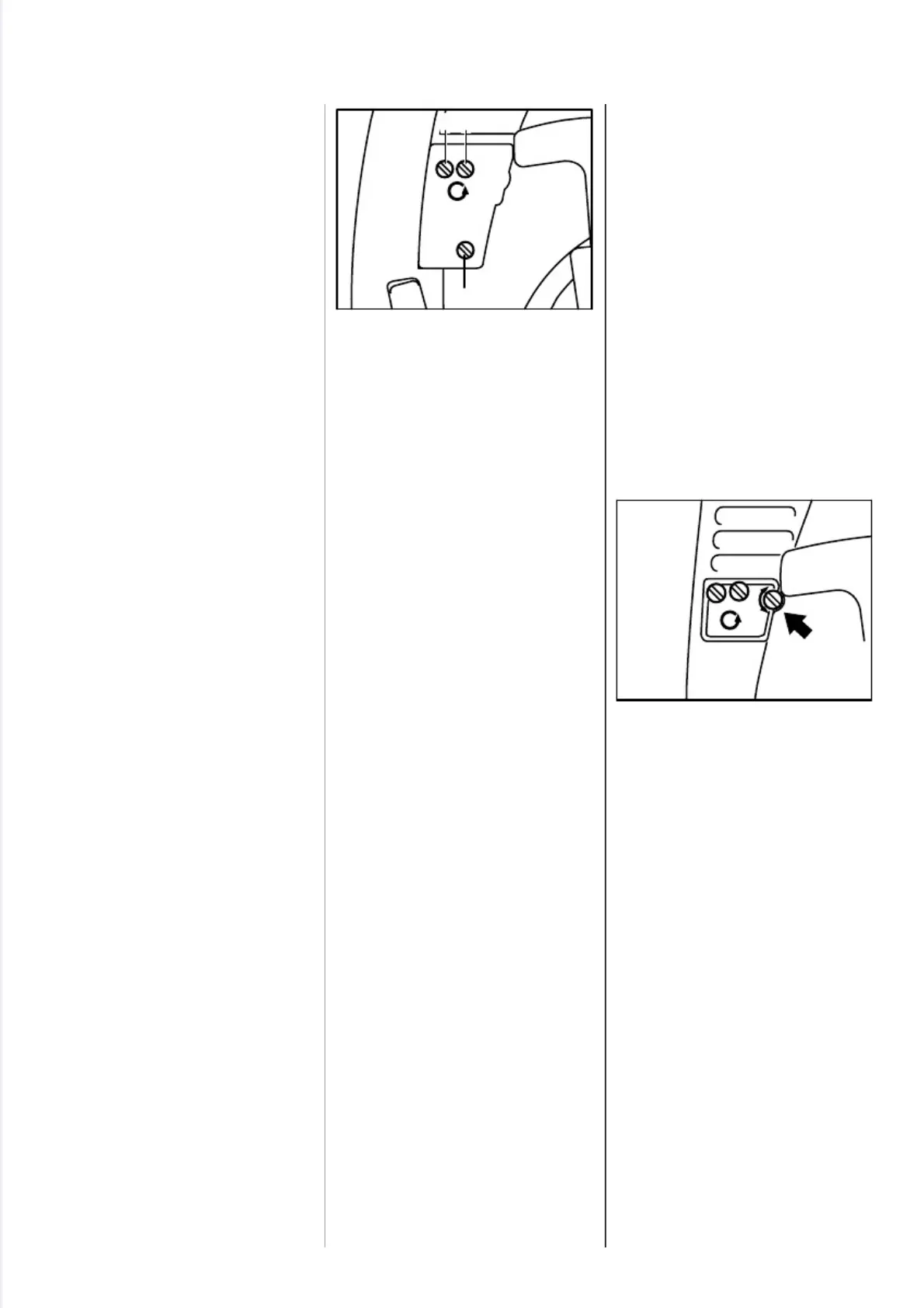

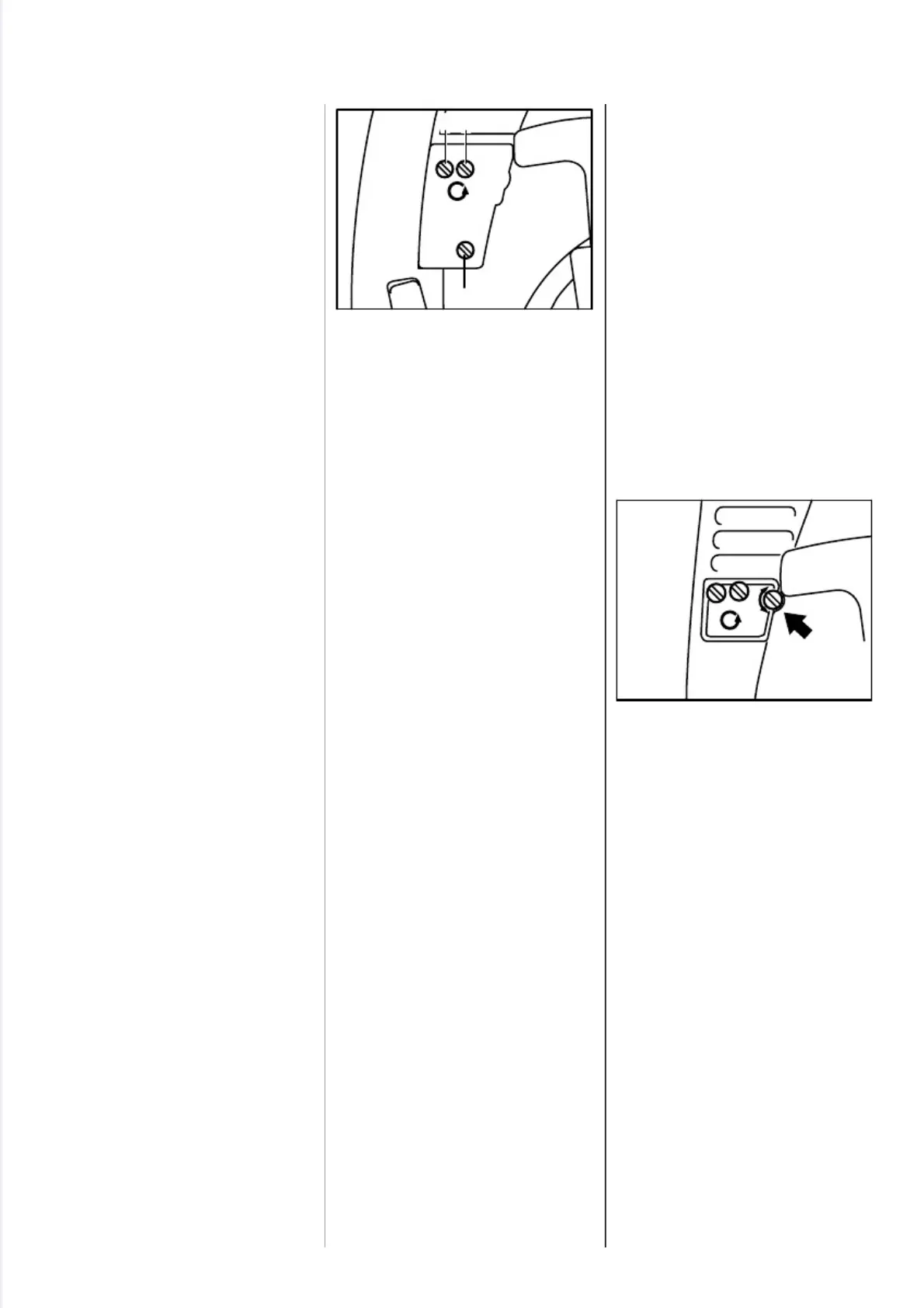

H

L

LA

2

5

0

R

A

2

2

0

1 2

3

V

A

2

5

0

R

A

2

2

1

1

H

L

LD

V

A

8.2.4 Adjusting

(three screws)

42 FS 120, 200, 300, 350, 400, 450, FR 350, 450

Loading...

Loading...