24 MS 210, MS 230, MS 250

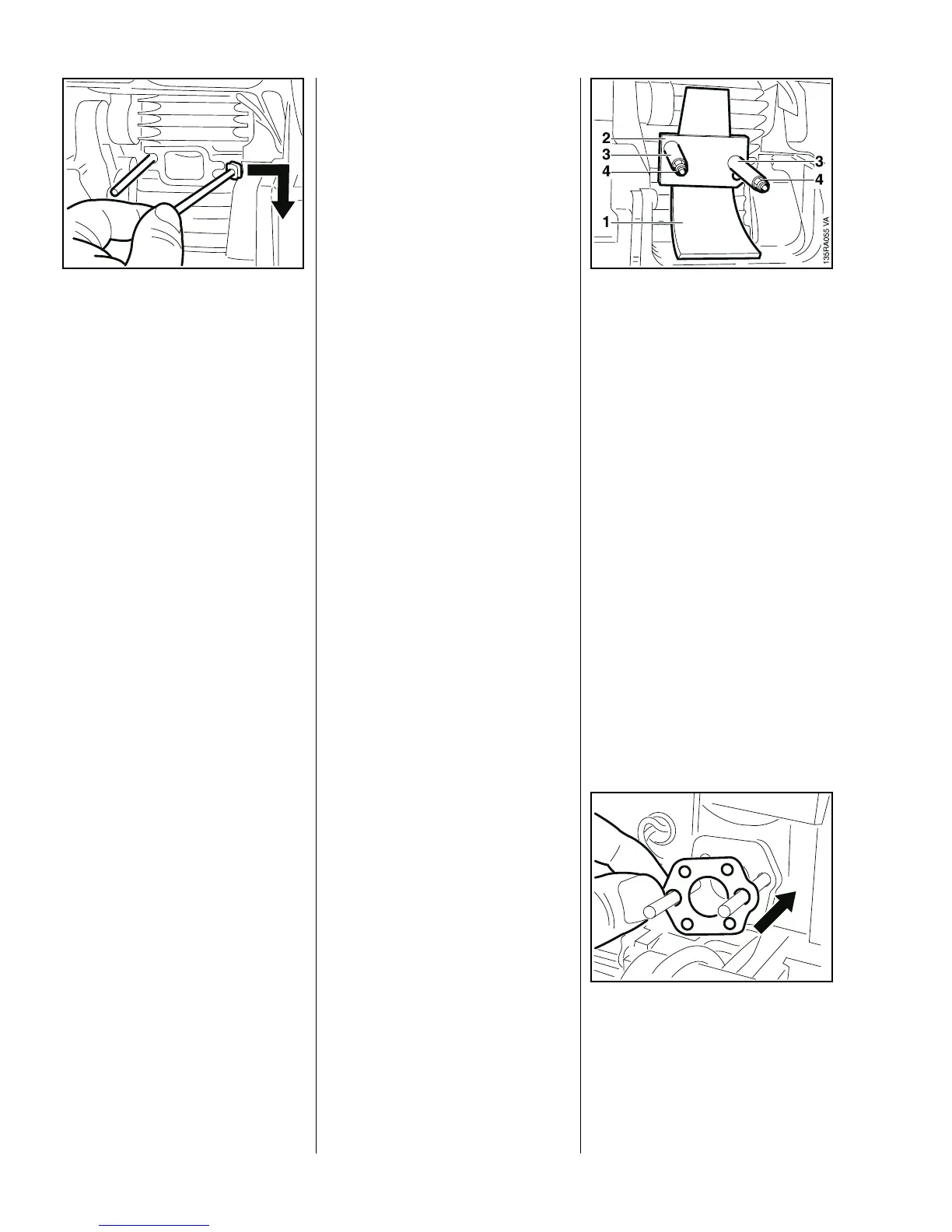

: Remove the screws from the

flange.

Reassemble in the reverse

sequence.

– Use a new gasket.

VA

135RA054

– Fit new locknuts and torque down

to 8.0 Nm (5.9 lbf.ft).

Defective oil seals and gaskets or

cracks in castings are the usual

causes of leaks. Such faults allow

supplementary air to enter the

engine and upset the fuel-air

mixture.

This makes adjustment of the

prescribed idle speed difficult, if not

impossible.

Moreover, the transition from idle

speed to part or full throttle is not

smooth.

The engine housing can be checked

thoroughly for leaks with the

carburetor and crankcase tester

and the vacuum pump.

– Remove the muffler – b 6.1.

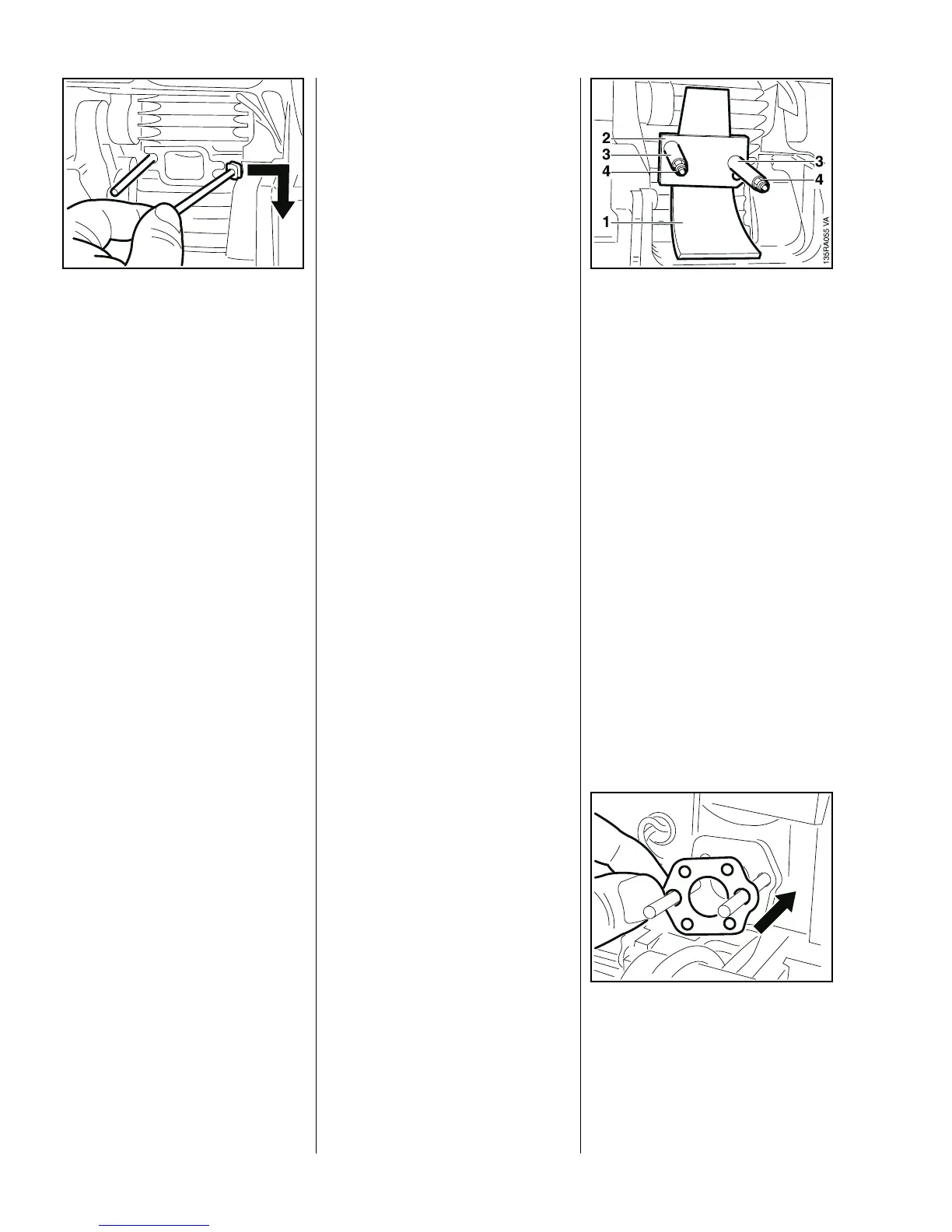

: Fit the sealing plate (1)

0000 855 8106 between the

mounting screws.

The sealing plate must completely

fill the space between the two

mounting screws.

: Slip the flange (2) 1123 855 4200

over the screws.

: Fit the sleeves (3) 1123 851 8300

on the screws.

: Fit the nuts (4) and tighten down

securely.

– Remove the carburetor –

b 11.2.2.

– Set the piston to top dead center

(T.D.C.). This can be checked

through the inlet port.

: Inspect carburetor gasket and fit

a new one if necessary.

VA

135RA056

6.2 Leakage Test 6.2.1 Preparations

Loading...

Loading...