RE 661, RE 661 PLUS, RE 961 PLUS

English

43

The tank may only be filled when the

heat exchanger is cold.

Fuel oil and diesel oil begin to congeal

due to the separation of paraffin at

temperatures near freezing point. This

can cause problems when starting the

burner.

To avoid such problems:

N Add anti-congealant to the fuel as

directed by the manufacturer

Bio-diesel oil must comply with the

DIN 51606 standard.

Organic bio-diesel oil may cause the

burner to malfunction after prolonged

storage, in the presence of extreme

temperatures or if transported

incorrectly.

N Open the cap (1)

N Fill with fuel oil grade EL or diesel oil

as defined by DIN 51603. Organic

bio-diesel oil to DIN 51606 may also

be used.

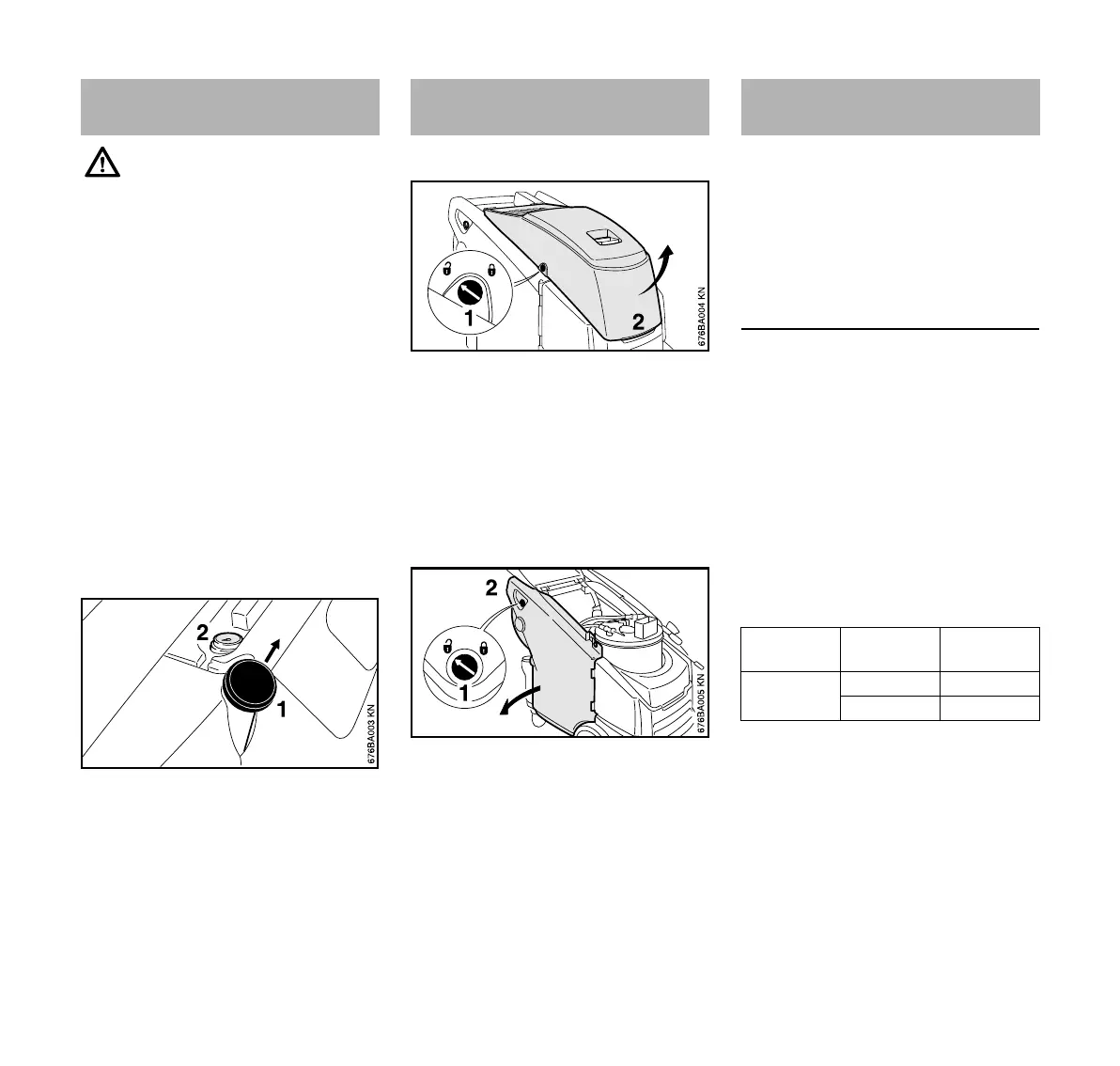

Open shroud

N Turn the screw (1)

counterclockwise until the shroud

can be swung upward

N Pull the grip (2) in the direction of

the arrow to open the shroud

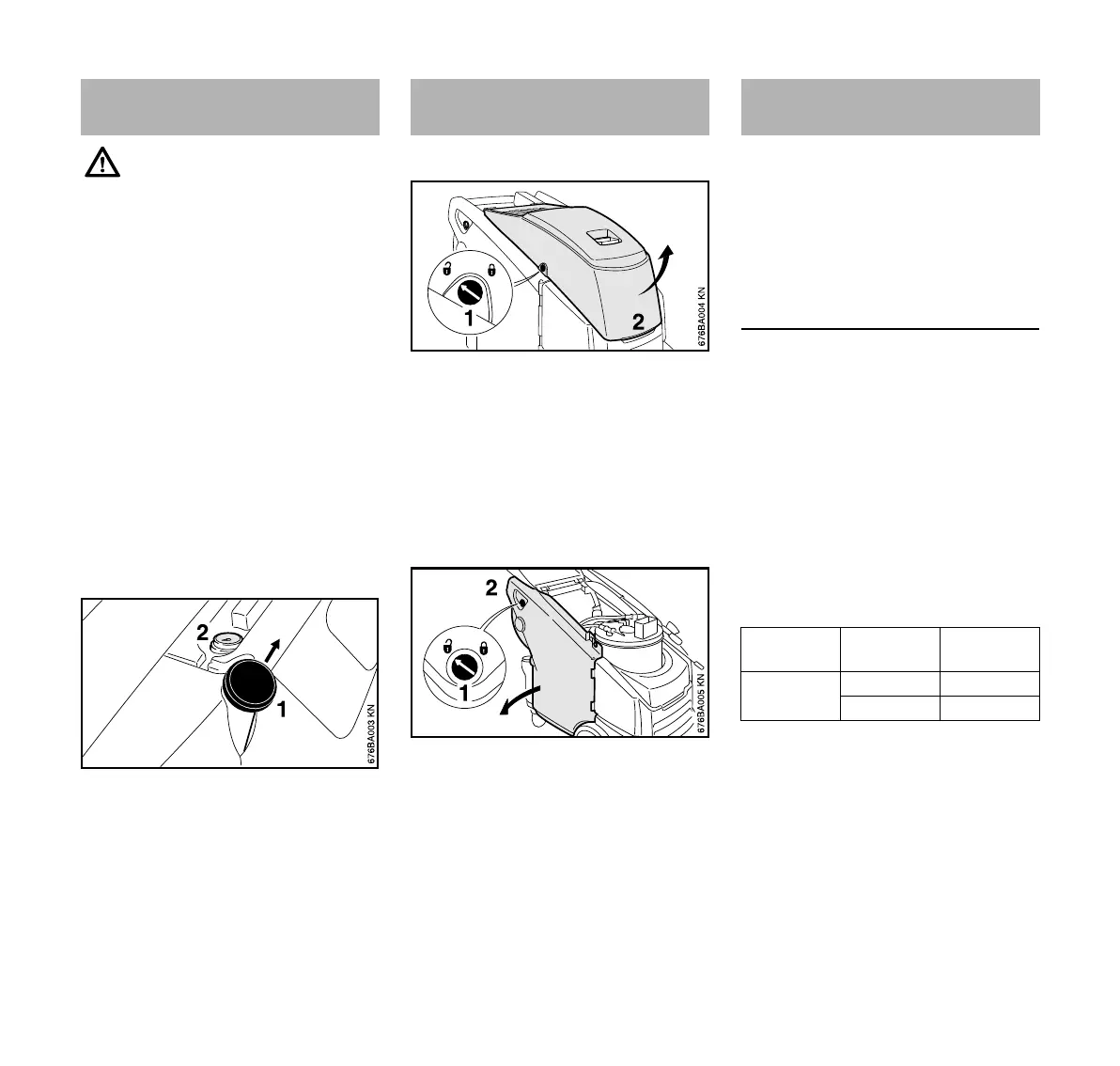

Open cover

Swing cover up only when the shroud is

open.

N Turn the knob (1) counterclockwise

until the cover can be swung

upward

N Pull the grip (2) in the direction of

the arrow to open the cover

Under normal operating conditions it is

not necessary to descale the machine if

STIHL scale inhibitor is used

consistently STIHL scale inhibitor is

specially designed for

STIHL detergents.

Mixing STIHL scale inhibitor with

water

N Measure the water hardness or

contact your water supply company

to establish the water hardness

range

Depending on water hardness – see

table:

N Mix scale inhibitor at a ratio of A : B

with clean water – maximum

capacity of the storage tank = 1 l

– A = scale inhibitor

– B=water

Fill fuel tank

Unsuitable fuels can be

dangerous.

Open shroud Add scale inhibitor

Unit water

hardness

Hardness

range

Mixing ratio

(A : B)

°dH < = 12 1 : 1

> 12 undiluted

Loading...

Loading...