LOWER UNIT 9-9

INSPECTION

NOTE:

If excessive ware, cracks, defective or other damage is found on

any component, replace component.

NOTE:

Thoroughly wash all metal components with cleaning solvent

and dry with compressed air.

!

Wear safety grasses when using compressed air.

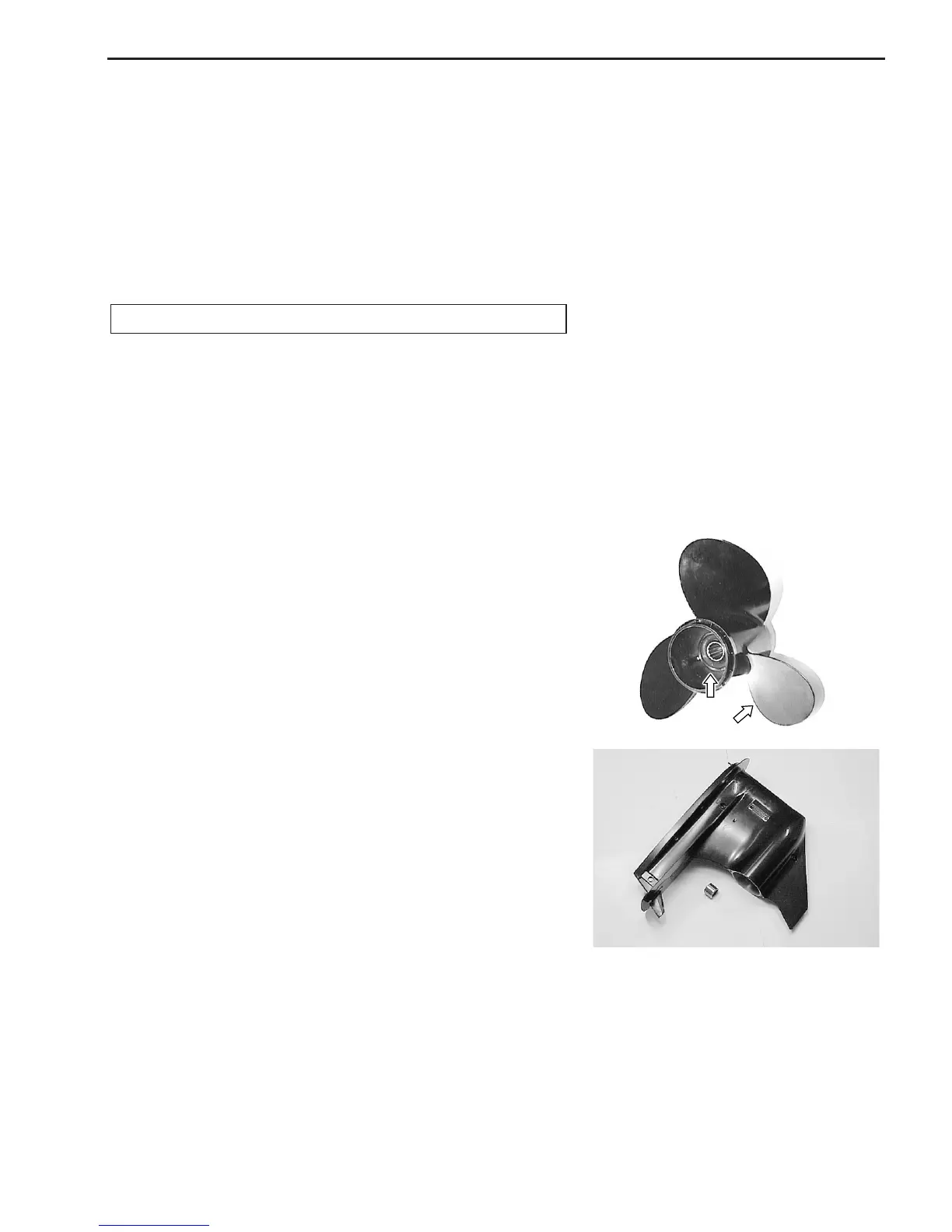

PROPELLER

• Inspect the propeller for bent, chipped or broken blades.

Replace or repair if necessary.

• Inspect the propeller bushing splines for wear or other dam-

age. Replace if necessary.

• Inspect the propeller bushing for deterioration or slipping.

Replace if necessary.

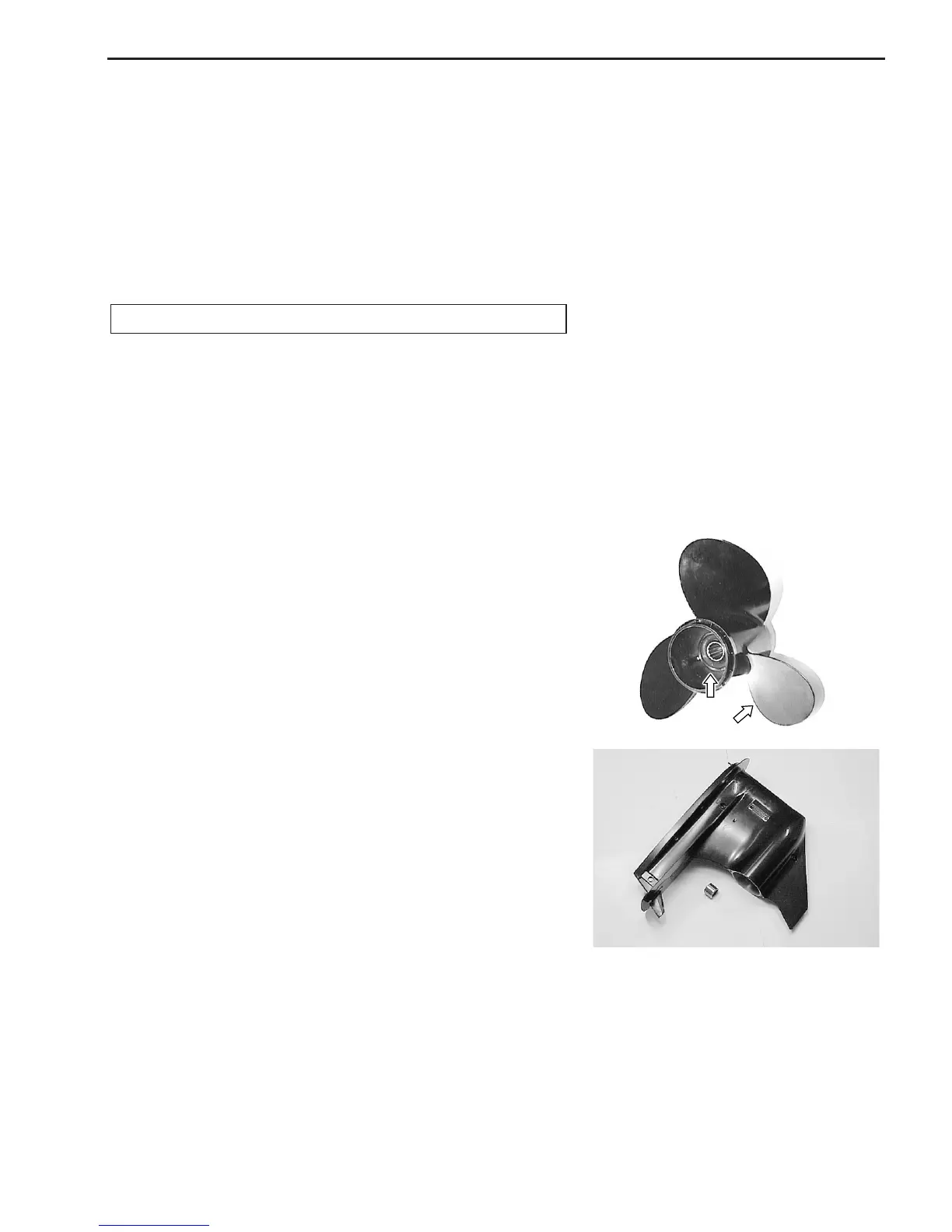

GEARCASE

• Inspect the gearcase for cracks or other damage.

Replace if necessary.

• Inspect the pinion bearing for pitting, rough or other damage.

Replace if necessary.

NOTE:

If removal and replacement are required, see the “PINION

BEARING” section on the page 9-7.

Loading...

Loading...