KIT PARTS INSTALLATION PROCEDURES

This manual explains the installation, handling, setting and other important procedures for each component

of the kit parts. For more fundamental works not contained in this manual, refer to RGV250 Service

Manual.

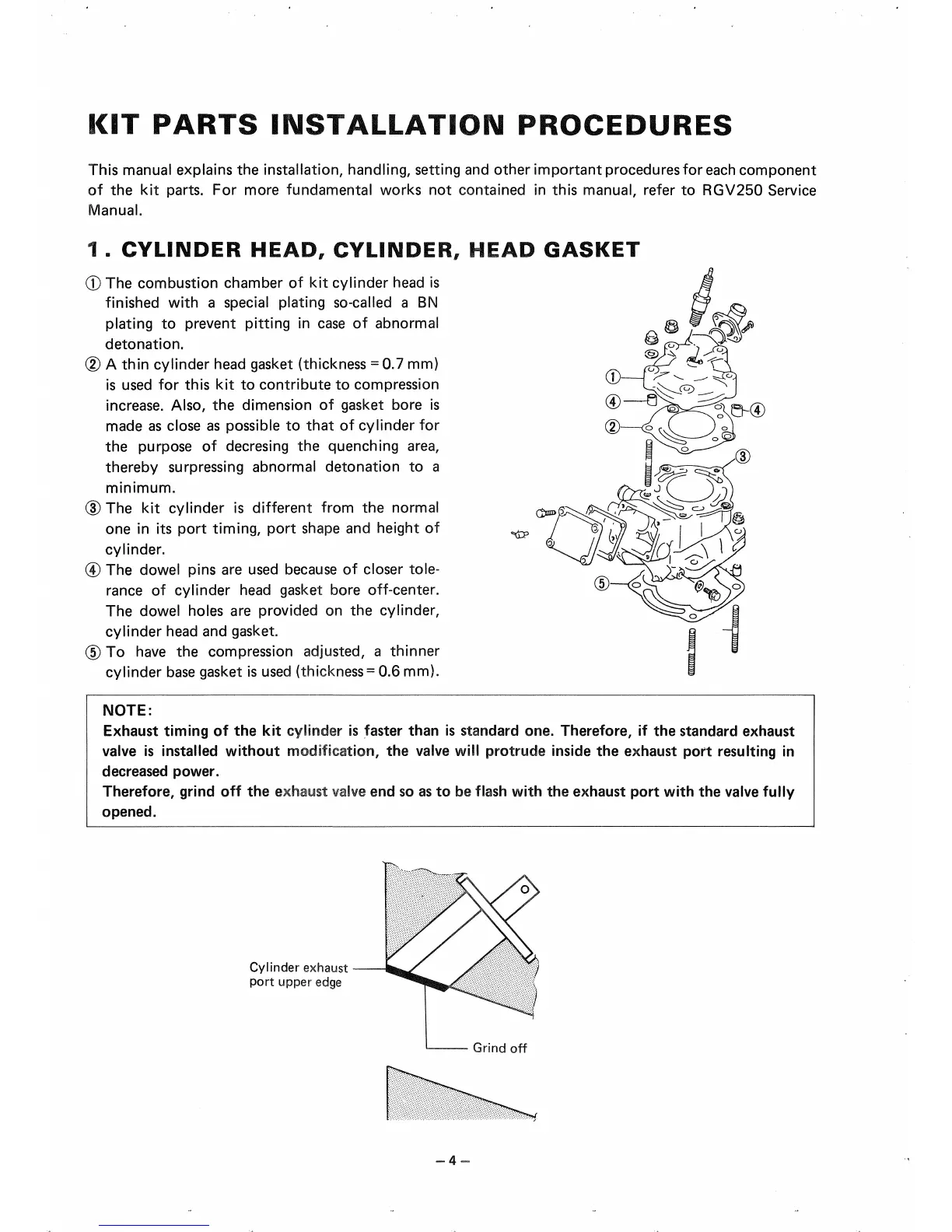

1 . CYLINDER HEAD, CYLINDER, HEAD GASKET

0 The combustion chamber of kit cylinder head is

finished with a special plating so-called a BN

plating to prevent pitting in case of abnormal

detonation.

(D A thin cylinder head gasket (thickness = 0.7 mm)

is used for this kit to contribute to compression

increase. Also, the dimension of gasket bore is

made as close as possible to that of cylinder for

the purpose of decresing the quenching area,

thereby surpressing abnormal detonation to a

minimum.

(D The kit cylinder is different from the normal

one in its port timing, port shape and height of

cylinder.

® The dowel pins are used because of closer tole-

rance of cylinder head gasket bore off-center.

The dowel holes are provided on the cylinder,

cylinder head and gasket.

(5) To have the compression adjusted, a thinner

cylinder base gasket is used (thickness = 0.6 mm).

^tp

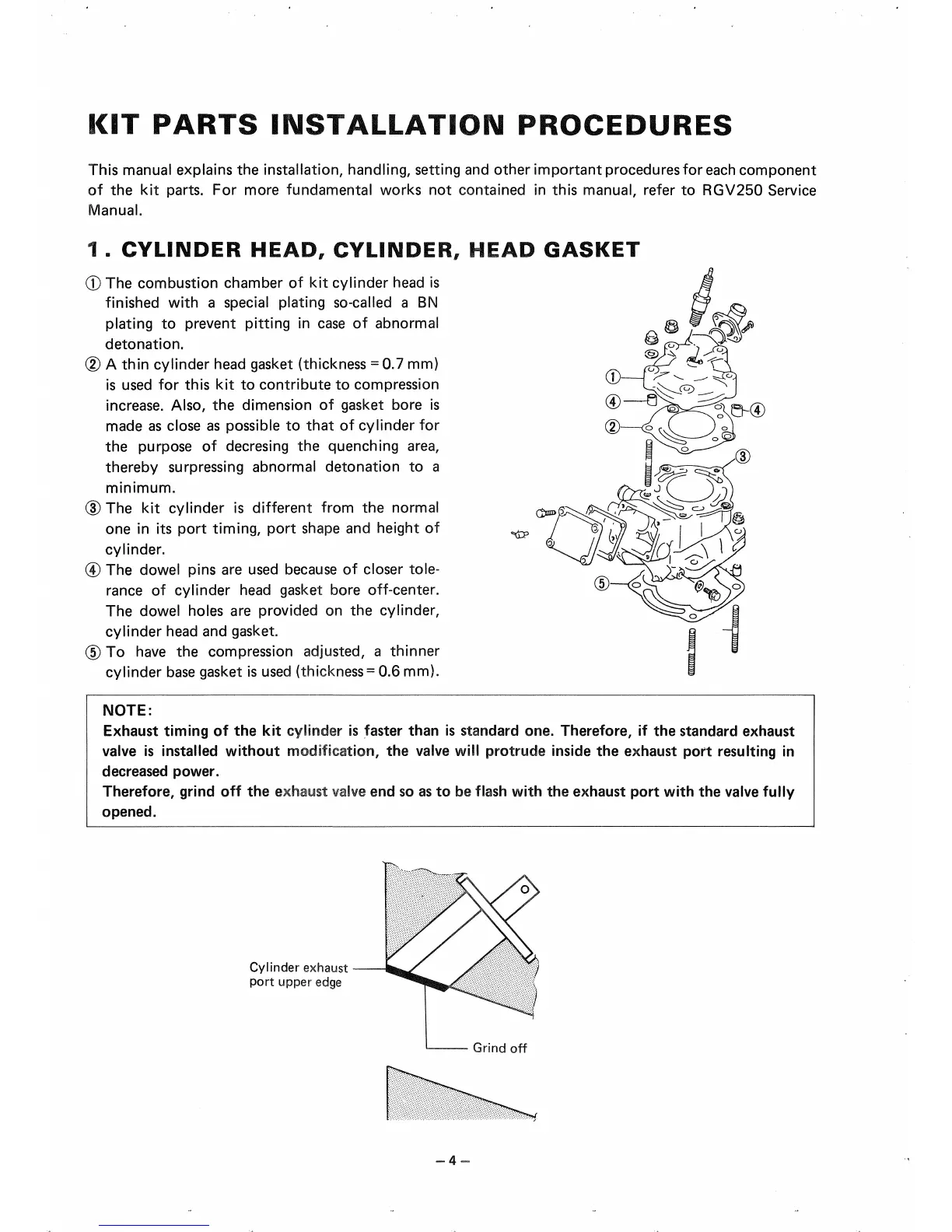

NOTE:

Exhaust timing of the kit cylinder is faster than is standard one. Therefore, if the standard exhaust

valve is installed without modification, the valve will protrude inside the exhaust port resulting in

decreased power.

Therefore, grind off the exhaust valve end so as to be flash with the exhaust port with the valve fully

opened.

Cylinder exhaust

port upper edge

Grind off

Loading...

Loading...