Geniox Air Handling Unit - User Manual | 3060386

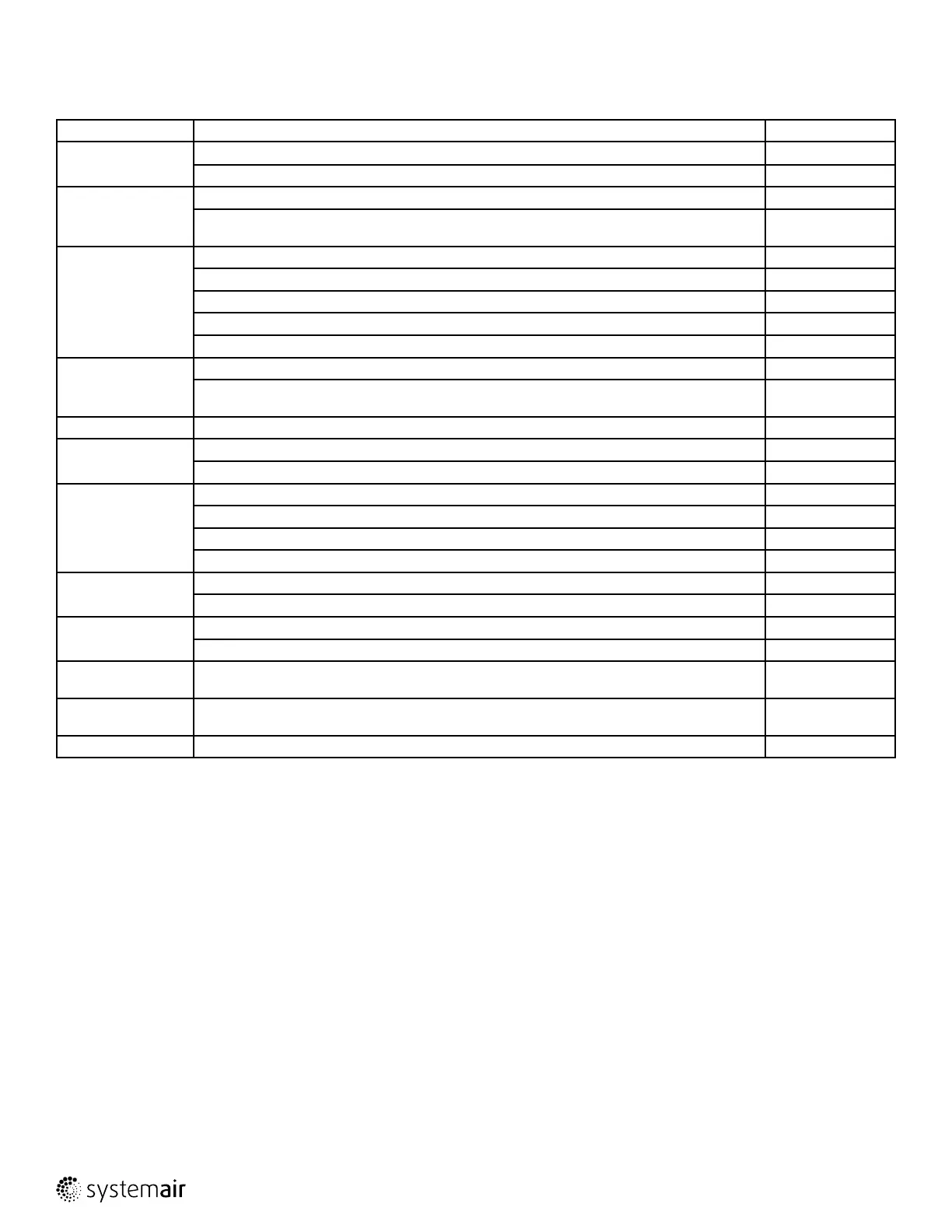

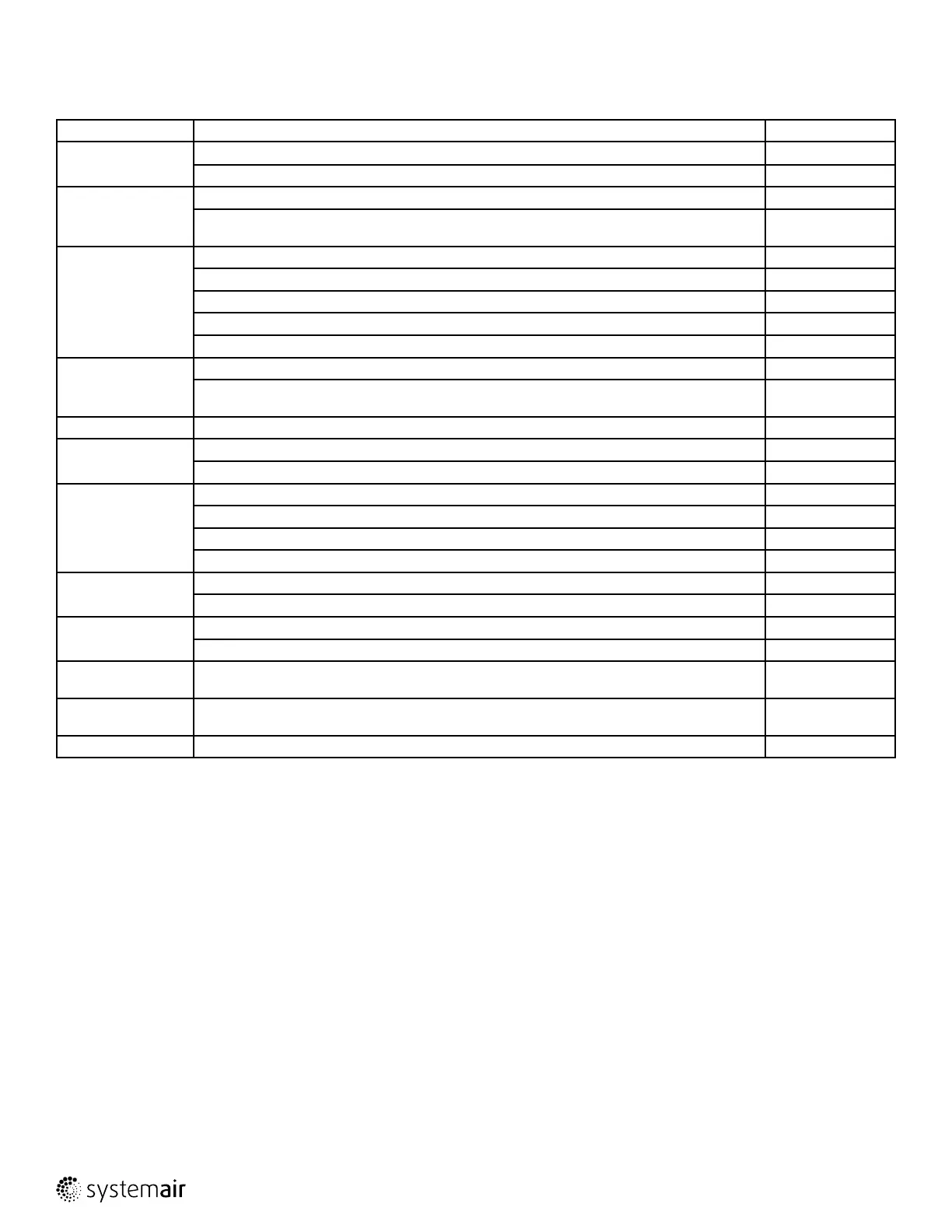

M.3 Recommended maintenance intervals

Function Maintenance Number per year

Unit casing Cleaning of the unit casing 1

Control of rubber seals on doors and between sections. 1

Filters Change on demand by alarm and always minimum twice a year. 2

Control of rubber seals. Control of the system with lateral locking rails and handles on Geniox10 –

Geniox25.

2

Fans Cleaning of all parts. 1

Check motors and bearings 1

Check that the impellers are rotating without dissonance. 1

Check that anti-vibration mounts are intact. 1

Check that the unit is operation without vibrations after the cleaning, overhaul and maintenance. 1

Energy recovery

wheel

Checkthatleakageanddirtaccumulationisinsignicant 1

Check that the wheel can turn freely and easily manually with a hand when the belt is removed from

the drive

1

Plate heat exchanger Check bypass function and sequence for de-icing 1

Dampers Test the operation. 1

Visual inspection of seals and tightness when closed. 1

Hot water coil Check the dirt accumulation and clean, if needed. 1

Bleeding, if needed. 1

Test of frost protection sequence 1

Test of circulation pump 1

Electric heating coil Check dirt accumulation and clean, if needed. 1

Test the function of the system with the fuses for the safety. 1

Cooling coil Check dirt accumulation and clean, if needed. 1

Test the frost protection (glycol) 1

Condensate drain Cleaning of tray, water trap and outlet. Check the electrical heating between insulation and pipes, if

installed.

1

Saving- and comfort

functions

Test of CO2 sensor, humidity sensor, motion sensor, pressure transmitters for air capacity control,

extended operation via button, cooling recovery, free cooling.

1

Fire alarm Testofthermostats,smokedetectorsandredetectionsystems 1

M.4 Filters – always replace lters with new lters with the same characteristics

Filtersinsupplyairandinreturnairalwayshavethesamesizesofframesandthenumberofltersarealwaysthesame.REMEMBERto

orderltersforsupplyairaswellasforreturnair.

Tomaintainsameleveloffanpowerconsumptionfortheair-handlingunit,itisveryimportantthatlterswiththesamecharacteristics

forstartpressureaswellaslifetimereplacefactory-mountedlters.

FilterframeforbagltersmustbeofNON-PVCplastictoensuresafedisposalbyincineration.

Foreachindividualairhandlingunityouwillndthedataforthefactory-mountedltersinAnnex2thatisalwaysprovidedina

coverplacedinsidetheairhandlingunitwhentheairhandlingunitisdeliveredtothenalsite.Annex2isalsoalwaysavailablefrom

Systemair if you can inform us of the production number of the air handling unit. The production number is always printed on the serial

platethatisattachedtotheunit.Youwillndanexampleofthisserialplateinsectiond.2.1ofthismanual.

Theseairhandlingunitsareavailablewithlterssizesmentionedbelowinthetable:

36 | Adjustment and maintenance operations

Loading...

Loading...