Maintenance-314 Service

Troubleshooting Techniques

This troubleshooting procedure is arranged to check

the simple trouble possibilities before proceeding with

extensive procedures. The first few checks ensure proper

connections, operation, and calibration. If the trouble is

not located by these checks, the remaining steps aid in

locating defective components.

1. Check Control Settings.

lncorrect control settings

can indicate a trouble that does not exist. If there is any

question about the correct function or operation of any

control, see the Operators Manual.

2. Check Associated Equipment.

Before proceeding

with troubleshooting, be certain that the equipment used

with the 314 is operating and connected correctly. Check

for a defective power supply and interconnecting cables.

3.

Visual Check.

Many troubles (such as unsoldered

connections, broken wires, damaged circuit boards,

damaged components, etc.) can be located by visual

inspection.

4. Check Instrument Calibration.

Check the calibra-

tion of the instrument, or the affected circuit if the trouble

appears to be in one circuit. The apparent trouble may be a

result of misadjustment and may be corrected by readjust-

ment. Complete adjustment instructions are given in the

Adjustment Procedure.

5.

Isolate Trouble to a Circuit.

To isolate trouble to a

circuit, note the trouble symptom. The symptom often

identifies the circuit in which the trouble is located. For

example, poor focus indicates that the crt circuit is

probably at fault. When trouble symptoms appear in more

than one circuit, check the affected circuits by checking

voltages.

lncorrect operation of all circuits often indicates trou-

ble in the power supply. Check first for correct voltagesof

the individual supplies and determine if one or more

supplies is out of regulation. However, a defective compo-

nent elsewhere in the instrument can appear as a

power-

supply trouble and may affect operation of other circuits.

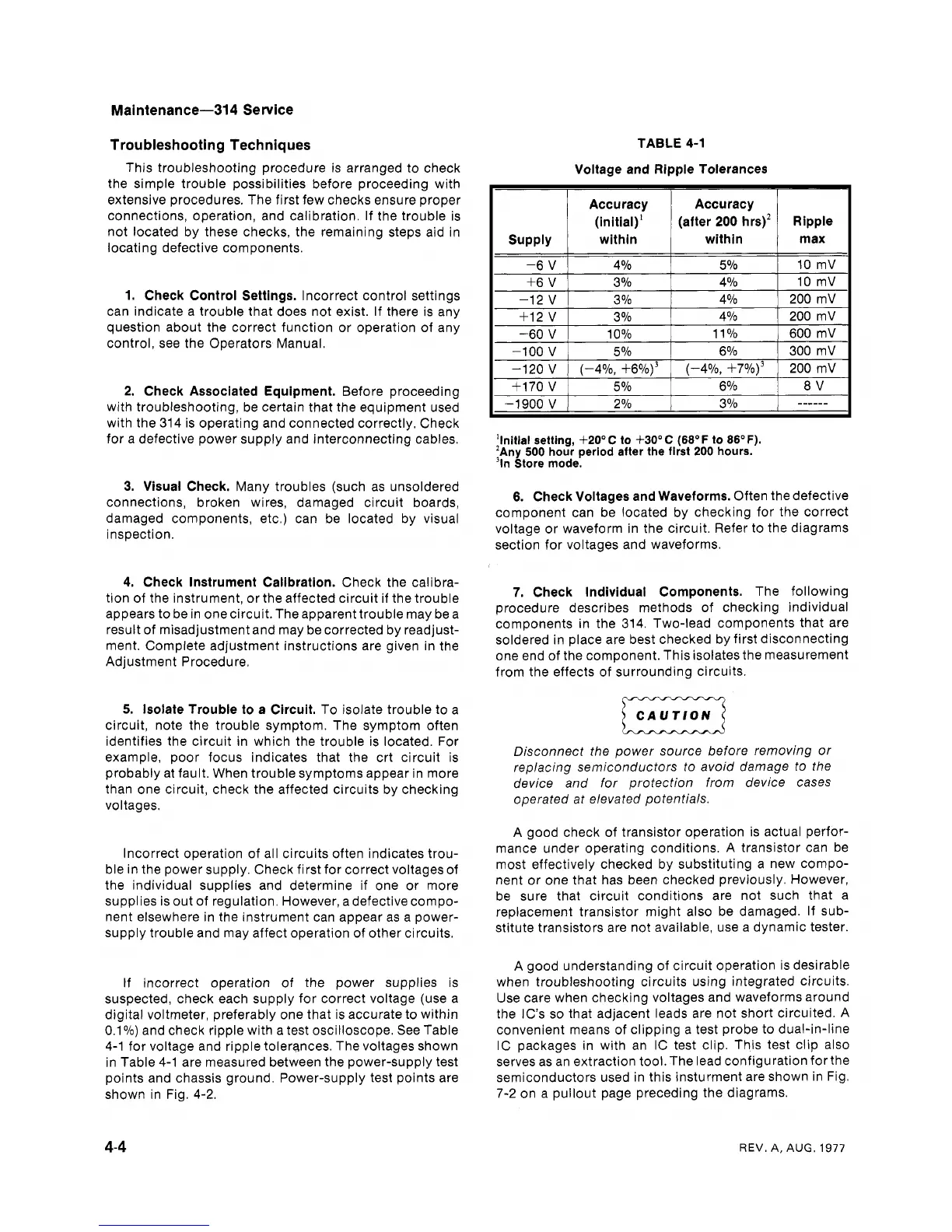

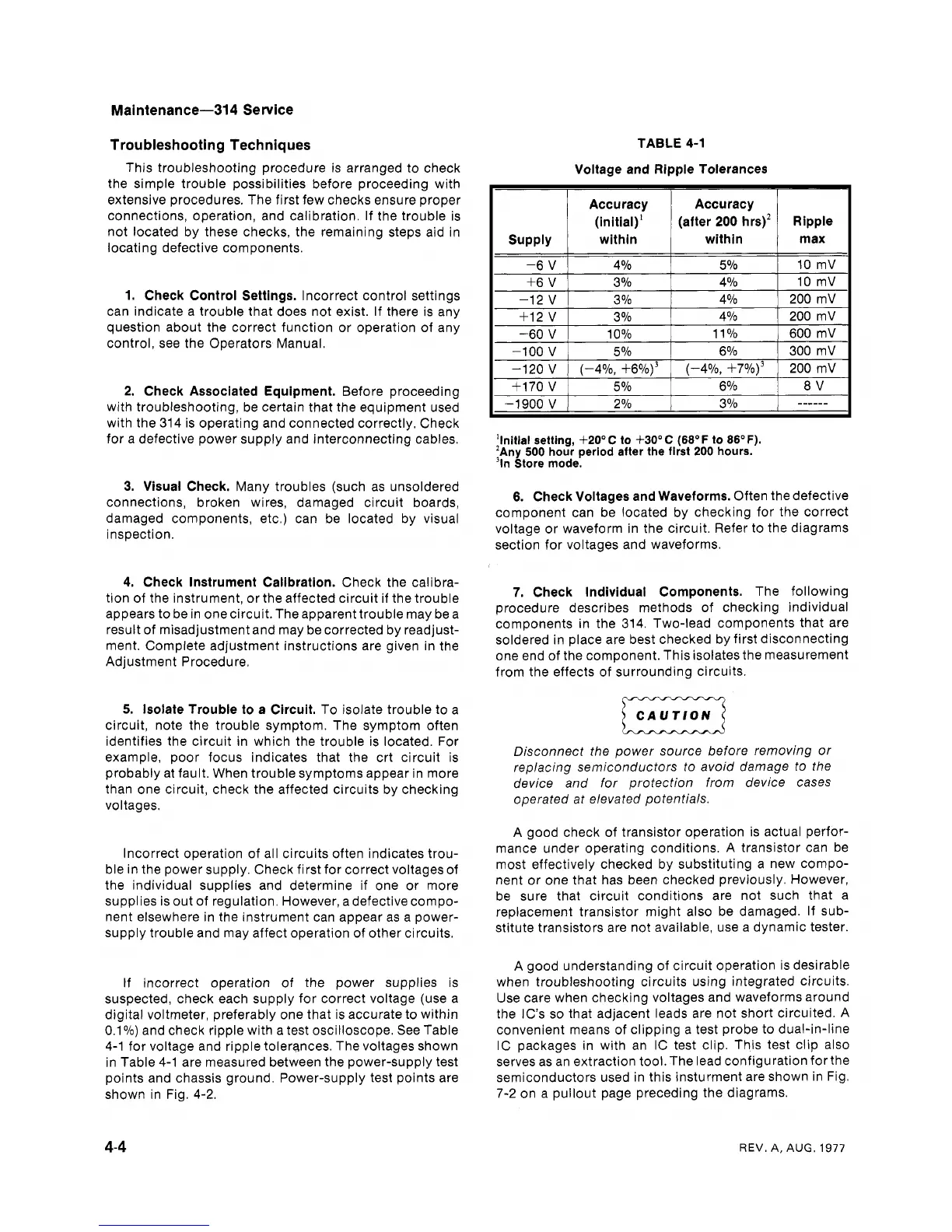

If incorrect operation of the power supplies is

suspected, check each supply for correct voltage (use a

digital voltmeter, preferably one that is accurate to within

0.1%) and check ripple with a test oscilloscope. See Table

4-1 for voltage and ripple

tolerqnces. The voltages shown

in Table 4-1 are measured between the power-supply test

points and chassis ground. Power-supply test points are

shown in Fig. 4-2.

TABLE 4-1

Voltage and Ripple Tolerances

Accuracy Accuracy

(initial)' (after 200 hrs)' Ripple

supply within within

+6

V

3

Oh

4% 10 mV

'Initial setting,

+20° C

to

+30°C (68'F

to

86OF).

'~ny

500

hour period after the first

200

hours.

"n

Store mode.

6.

Check Voltages and Waveforms.

Often the defective

component can be located by checking for the correct

voltage or waveform in the circuit. Refer to the diagrams

section for voltages and waveforms.

7.

Check Individual Components.

The following

procedure describes methods of checking individual

components in the 314. Two-lead components that are

soldered in place are best checked by first disconnecting

one end of the component. This isolates the measurement

from the effects of surrounding circuits.

CAUTION

a

Disconnect the power source before removing or

replacing semiconductors to avoid damage to the

device and for protection from device cases

operated at elevated potentials.

A good check of transistor operation is actual perfor-

mance under operating conditions. A transistor can be

most effectively checked by substituting a new compo-

nent or one that has been checked previously. However,

be sure that circuit conditions are not such that a

replacement transistor might also be damaged. If sub-

stitute transistors are not available, use a dynamic tester.

A good understanding of circuit operation is desirable

when troubleshooting circuits using integrated circuits.

Use care when checking voltages and waveforms around

the

IC's so that adjacent leads are not short circuited. A

convenient means of clipping a test probe to dual-in-line

IC packages in with an IC test clip. This test clip also

serves as an extraction

tool.The lead configuration forthe

semiconductors used in this insturment are shown in Fig.

7-2 on a pullout page preceding the diagrams.

REV.

A,

AUG.

1977

Loading...

Loading...