Creation: 01.31 - 2014 2-1-2

A. Maintenance

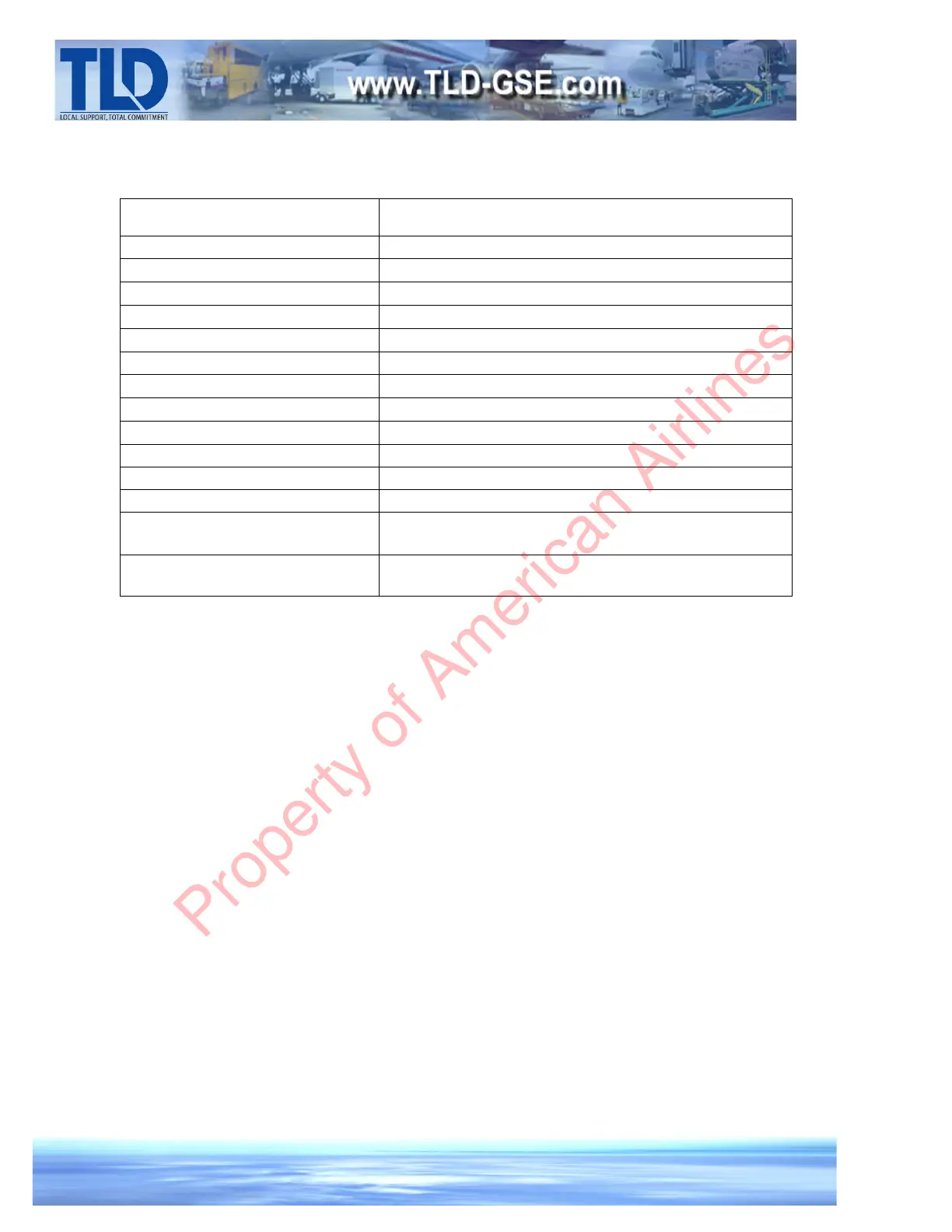

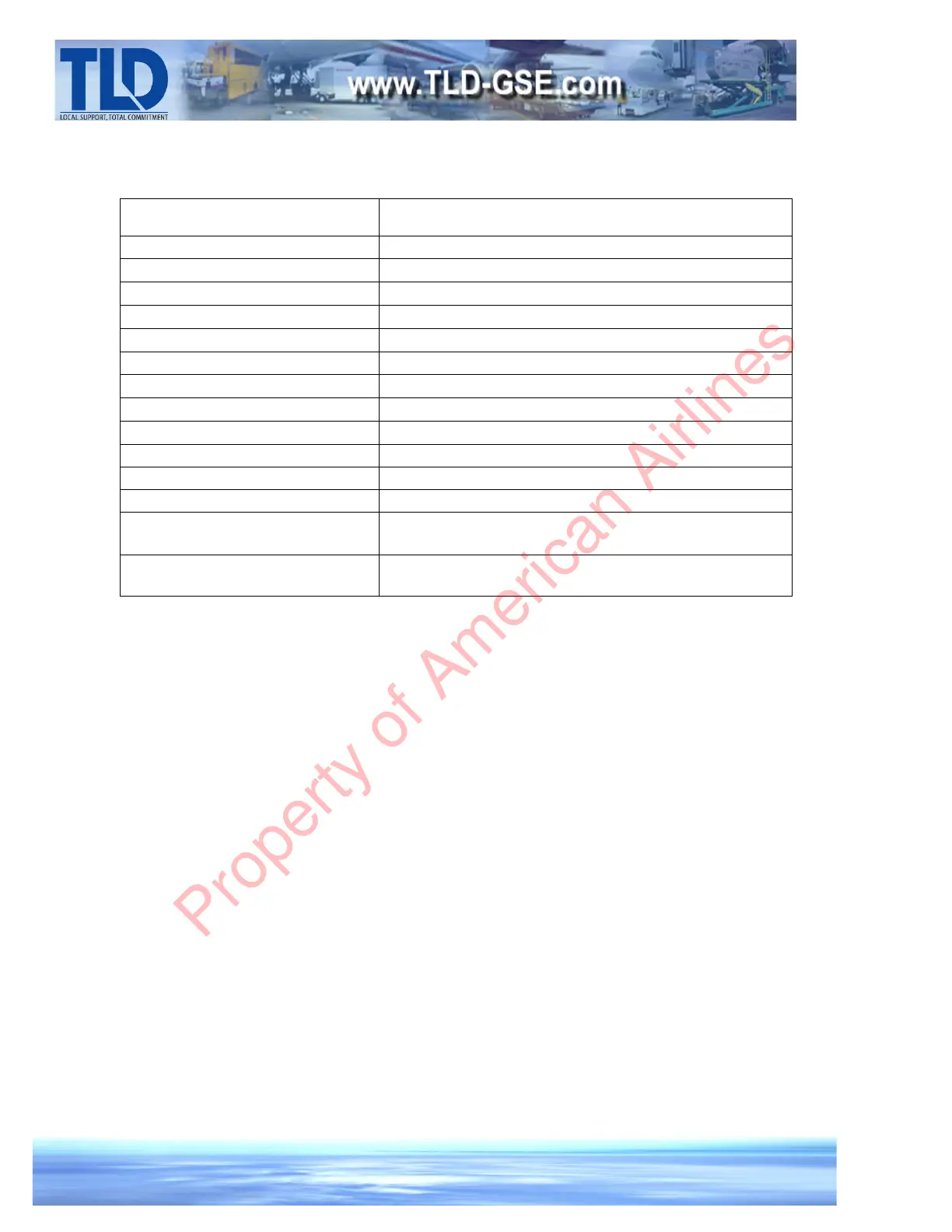

The following charts show the frequency of maintenance required on the listed components.

Component Maintenance Required

(1)

Engine air filter Check daily, replace when indicator turns red.*

Engine oil and filter Check daily; change every 500 hours.

DEF Filter (Tier 4 Final Only)

Check daily; change every 24 months.

Lubricate every 300 hours or 6 months

Fuel pre-filter/water separator

Wheels Rotate every 1200 hours or 24 months

Wheel hubs and fifth wheel hub Repack bearings every 24 months

Steam wash engine radiator

Repack bearings on wheel hubs

and fifth wheel hub

24 months

Inspect cables and cable head(s) 500 hours

* Change as required as shown by visual inspection.

** Always clean radiator from the front nose area of the unit.

(1) This operation should be performed at more frequent intervals under dusty or low temperature

conditions. The time schedules indicated in Chart 1 are approximate. They are based on average

conditions. Reduction of the interval shown may be necessary under harsh operating conditions

such as low engine temperature, excessively heavy loads, and high oil temperatures, or operation

in particularly arid or dusty environments.

LUBRICATION & MAINTENANCE BY HOURS - CHART 1

Property of American Airlines

Loading...

Loading...