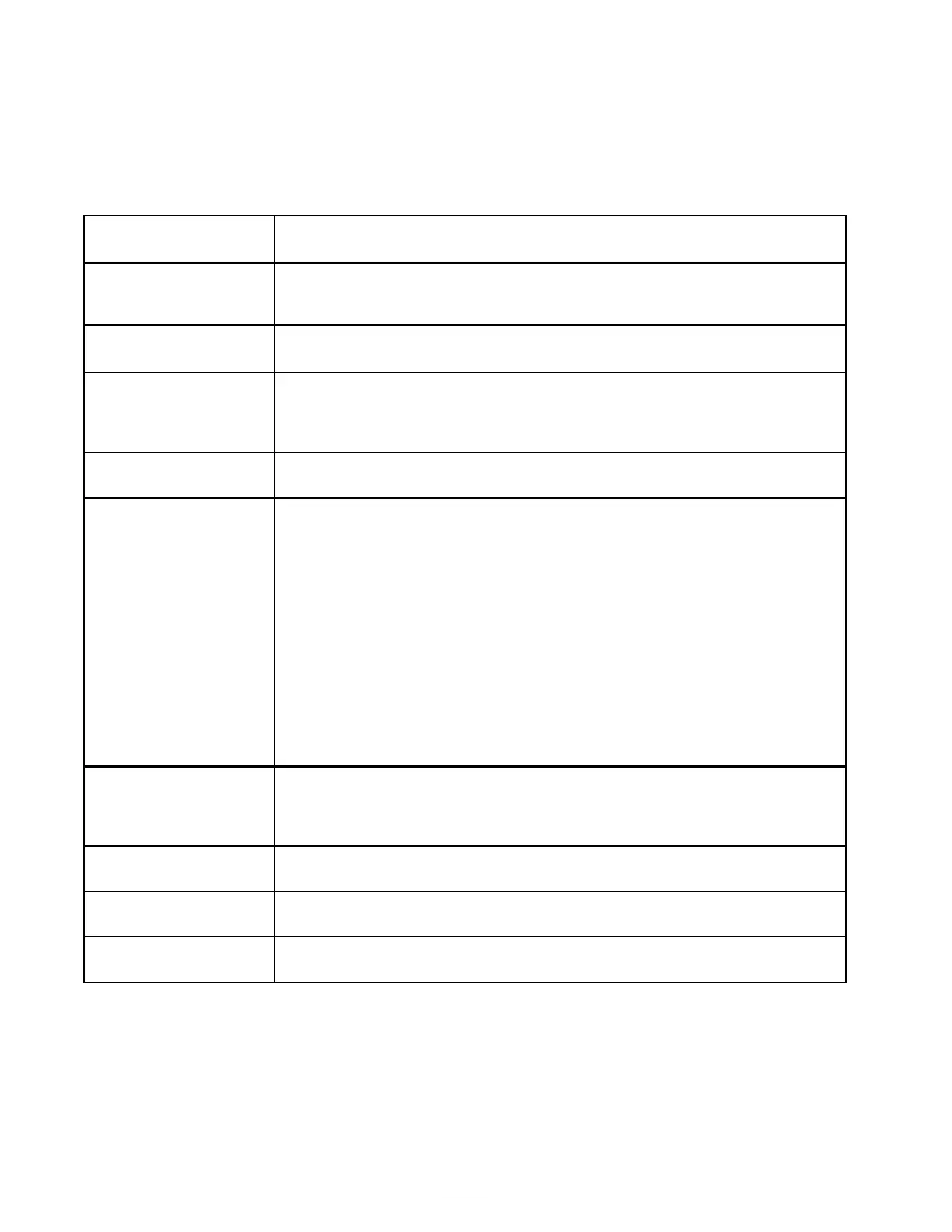

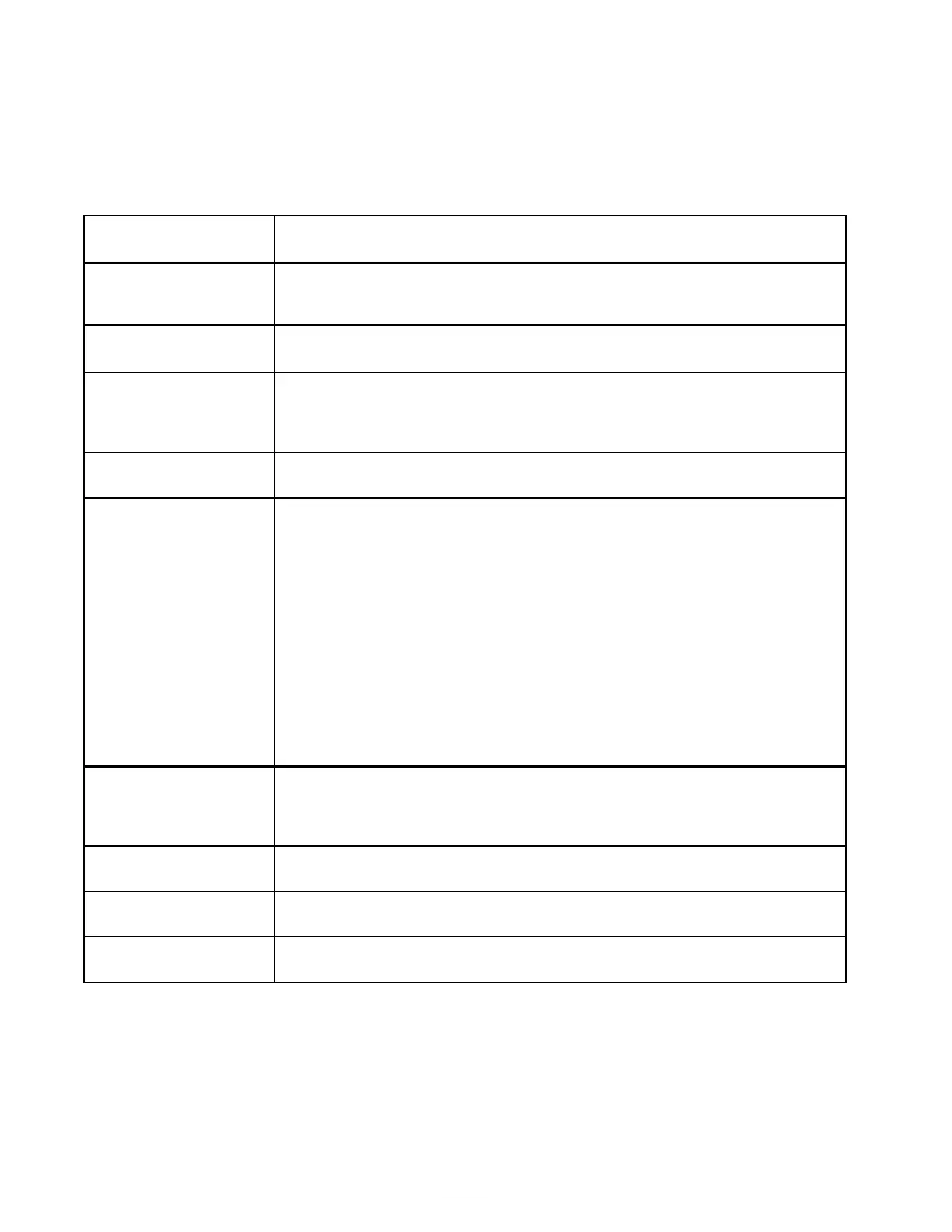

Maintenance

Note: Deter mine the left and right sides of the mac hine from the nor mal operating position.

Recommended Maintenance Schedule(s)

Maintenance Service

Interval

Maintenance Procedure

After the rst 8 operating

hours

• Check the engine oil.

• Check the condition and tension of the drive belt.

• Check the tension of the starter generator belt.

After the rst 25

operating hours

• Change the engine oil.

• Check the front wheel toe-in and front suspension.

Before each use or daily

• Check the engine oil.

• Check the tire pressure.

• Check the transmission oil level.

• Check the brake uid level.

Every 50 hours

• Check the battery cable connections for wear or damage.

• Check the battery electrolyte level.

Every 100 hours

• Grease the bearings and bushings.

• Inspect and clean the air lter element (twice as often in special operating

conditions; refer to Maintaining the Vehicle under Special Operating

Conditions).

• Change the engine oil (twice as often in special operating conditions; refer

to Maintaining the Vehicle under Special Operating Conditions).

• Check the spark plug.

• Check the operation of the Neutral gear shift position.

• Inspect the condition and wear of the tires.

•

Torque the wheel lug nuts to 45-65 ft-lb (61-88 N ⋅ m).

• Check the front wheel toe-in and front suspension.

• Clean the engine cooling areas (twice as often in special operating

conditions; refer to Maintaining the Vehicle under Special Operating

Conditions).

• Inspect the brakes.

Every 200 hours

• Replace the air lter element.

• Adjust the parking brake.

• Check the condition and tension of the drive belt.

• Check the tension of the starter generator belt.

Every 400 hours

• Inspect the fuel lines and connections.

• Clean and lubricate the primary drive clutch.

Every 800 hours

• Replace the fuel lter.

• Change the transaxle uid.

Yearly

• Complete all yearly maintenance procedures specied in the Engine

Operator’s Manual.

Important: R efer to y our Engine Operator’ s Man ual f or additional maintenance pr ocedur es.

28

Loading...

Loading...