T he dust in the clutch will become

airbor ne and could dama ge y our ey es or

y ou could inhale it causing br eathing

dif ficulties.

W ear safety go g g les and a dust mask

or other ey e and r espirator y pr otection

when perf or ming this pr ocedur e.

5. Lubricate the mo ving par ts in the areas circled

in Figure 47 using T oro Dr y Lubricant Spra y ,

a v ailable through y our A uthorized T oro Dealer

or Distributor .

Figure 47

6. Install the clutc h co v er and secure it with the 3

bolts remo v ed previously .

Changing the Transaxle

Fluid

Chang e the transaxle fluid ev er y 800 operating

hours or yearly , whic hev er occurs first.

1. P osition the v ehicle on a lev el surface , set

the parking brak e , tur n the ignition off , and

remo v e the k ey .

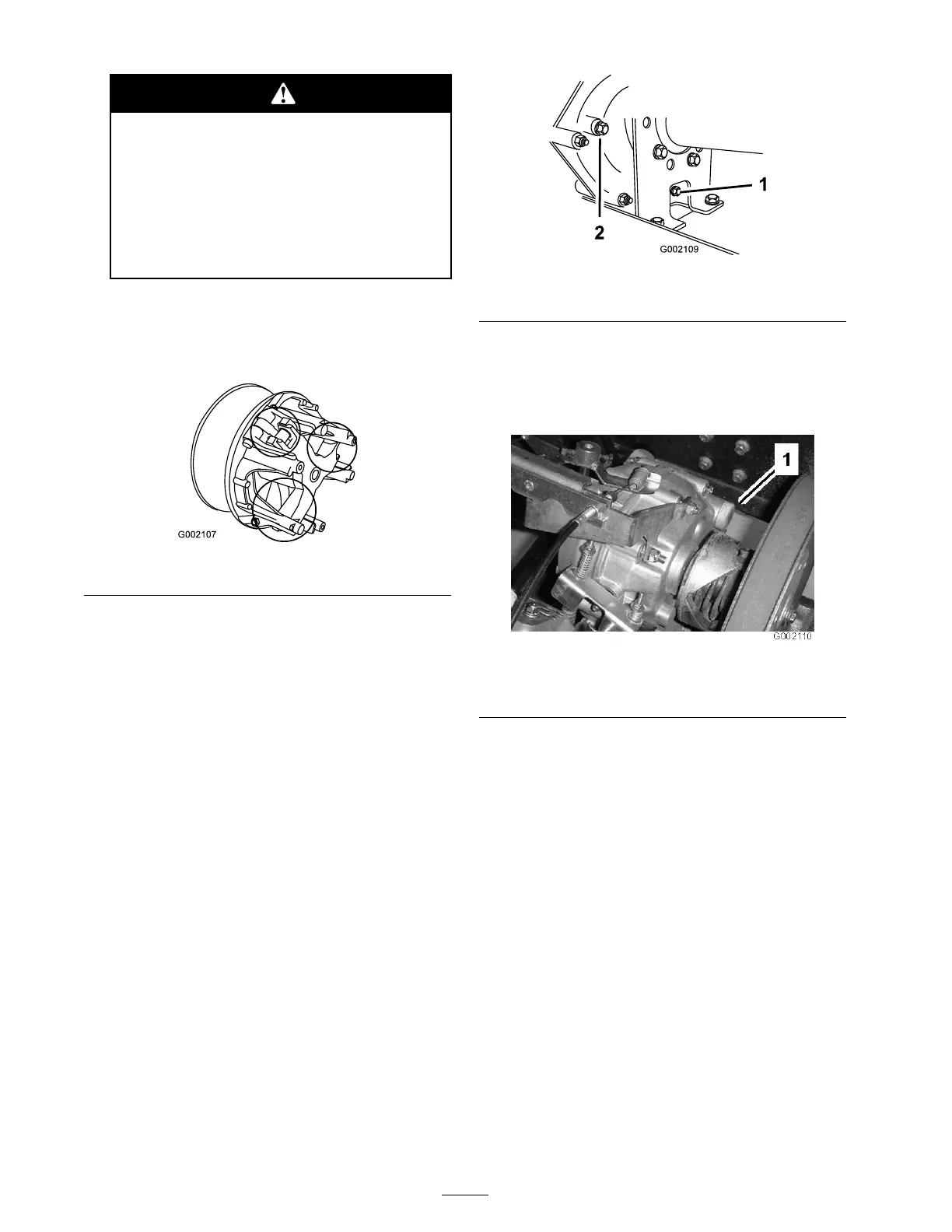

2. R emo v e the drain plug from the right side of

the reser v oir ( Figure 48 ) and let the fluid flo w

into a drain pan. Install and tighten the plug

when the fluid stops draining .

Note: Dispose of the used oil at a cer tified

recycling center .

Figure 48

1. Drain plug 2. Level indicator hole

3. Fill the reser v oir ( Figure 49 ) with appro ximately

1-1/2 qt. (1.4 liters) of SAE 10W30 motor oil

or until the oil lev el is at the bottom of the

lev el indicator hole ( Figure 48 ).

Figure 49

1. Oil ll

4. Star t the engine and operate it to fill the

system. R ec hec k the oil lev el and re plenish it,

if required.

Cooling System

Maintenance

Cleaning the Engine Cooling

Areas

Clean the rotating screen, cooling fins , and exter nal

surfaces of the engine ev er y 100 operating hours

or more often under extremely dusty and dir ty

conditions .

Important: Operating the engine with a

block ed r otating scr een, dir ty or plug ged

cooling fins, or cooling shr ouds r emo v ed will

cause engine dama ge due to o v erheating .

40

Loading...

Loading...