Premaintenance

Procedures

Maintaining the Vehicle

under Special Operating

Conditions

If the v ehicle is subjected to any of the conditions

listed belo w , maintenance should be perfor med

twice as frequently .

• Deser t operation

• Cold climate operation (belo w 50 deg rees F

[10 deg rees C])

• T railer to wing

• Dri ving time typically less than 5 min utes

• F requent operation in dusty conditions

• Constr uction w ork

• After extended operation in m ud, sand, w ater ,

or similar dir ty conditions , ha v e y our brak es

inspected and cleaned as soon as possible . T his

will prev ent any abrasi v e material from causing

ex cessi v e w ear .

• Under frequent hea vy duty operating

conditions , lubricate all g rease fittings and

inspect air cleaner daily to prev ent ex cessi v e

w ear .

Jacking the Vehicle

W henev er the engine is r un for routine

maintenance and/or engine diagnostics , the rear

wheels of the v ehicle should be 1 inc h (25 mm)

off the g round with the rear axle suppor ted on

jac k stands .

T he v ehicle may be unsta ble when using

a jack. It could slip of f the jack, injuring

an y one beneath it.

• Do not star t the engine while the v ehicle

is on a jack.

• Al w ays r emo v e the k ey fr om the ignition

bef or e getting of f of the v ehicle.

• Block the tir es when the v ehicle is on a

jack.

T he jac king point at the front of the v ehicle is on

the front of the frame behind the to wing tongue

( Figure 29 ) T he jac king point at the rear of the

v ehicle is under the axle tubes ( Figure 30 ).

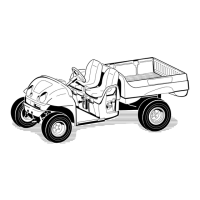

Figure 29

1. Front jacking point

Figure 30

1. Rear jacking points

Lubrication

Lubricate all of the bearings and bushings ev er y

100 hours or once a year , whic hev er occurs first.

Grease them more frequently when using the

v ehicle for hea vy-duty operations .

Grease T ype: Number 2 General Pur pose Lithium

Base Grease

Adding Grease

1. Wipe the g rease fitting clean so foreign matter

cannot be forced into the bearing or bushing .

2. Pump g rease into the bearing or bushing .

3. Wipe off ex cess g rease .

30

Loading...

Loading...