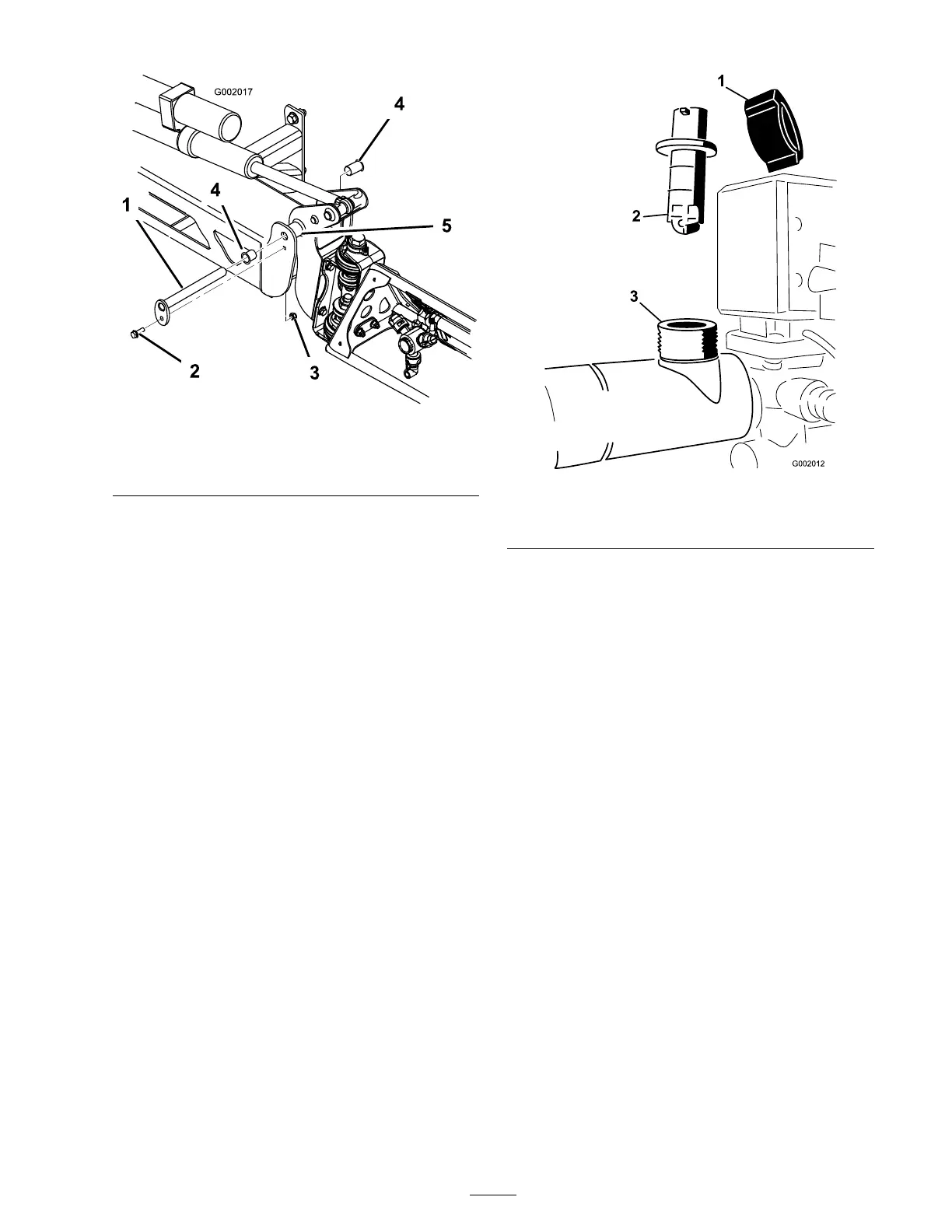

Figure 73

1. Pivot pin

4. Nylon bushing

2. Bolt 5. Pivot bracket

3. Nut

4. R emo v e the boom and pi v ot brac k et assembly

from the center frame to access the nylon

bushings .

5. R emo v e and inspect the nylon bushings from

the front and bac k sides of the pi v ot brac k et

( Figure 73 ). R e place any damag ed bushings .

6. Place a small amount of oil on the nylon

bushings and install them into pi v ot brac k et.

7. Install the boom and pi v ot brac k et assembly

into the center frame , aligning the openings

( Figure 73 ).

8. Install the pi v ot pin and secure it with the bolt

and n ut remo v ed previously .

R e peat the procedure for eac h boom.

Cleaning

Cleaning the Flowmeter

Occasionally , the flo wmeter ma y need to be

cleaned to remo v e an obstr uction.

Note: Mak e sure the pump is off when

perfor ming this procedure .

1. Disconnect the flo wmeter wire from wiring

har ness .

2. R emo v e the retaining cap from the flo wmeter

body ( Figure 74 ).

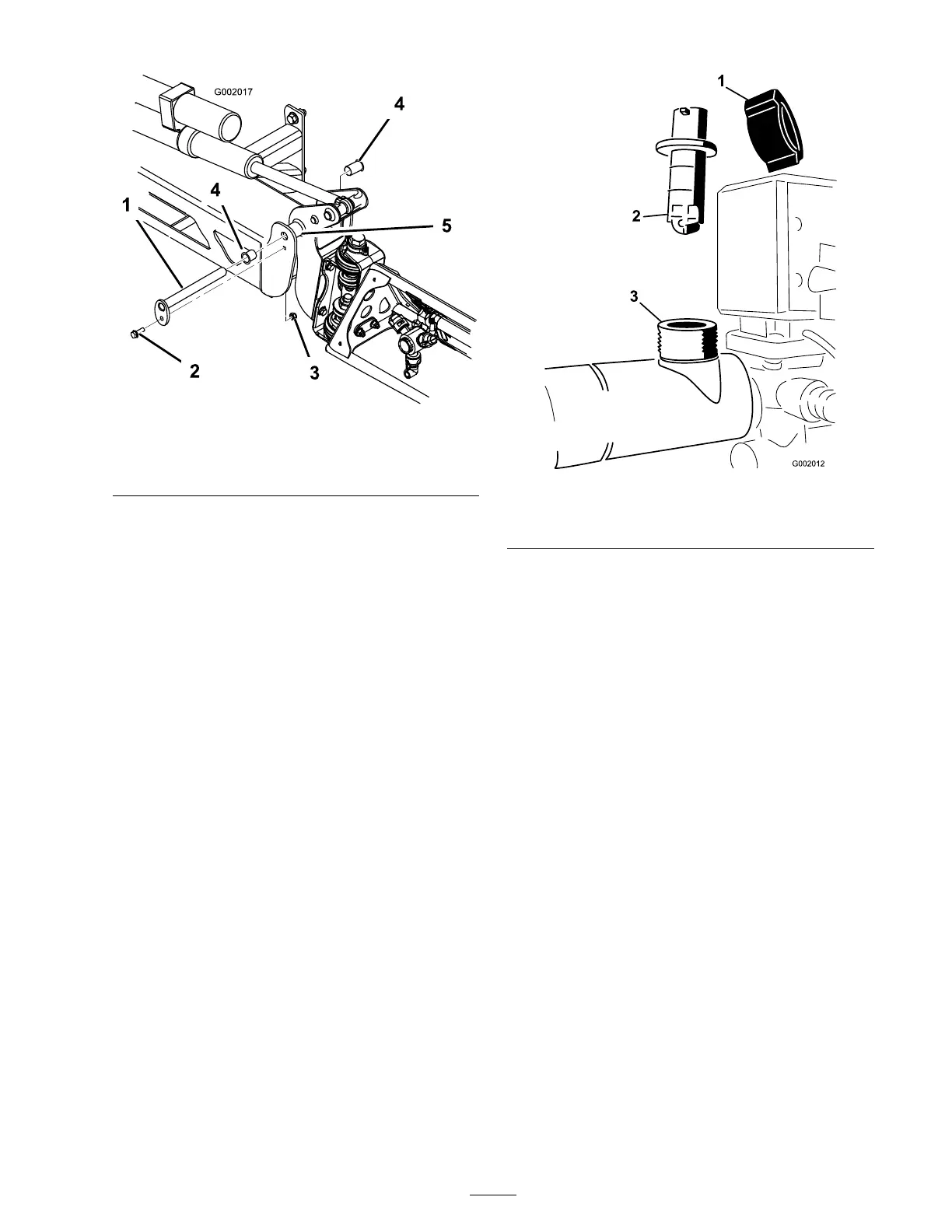

Figure 74

1. Retaining cap

3. Flowmeter body

2. Paddle wheel assembly

3. Carefully pull the paddle wheel assembly from

the body .

4. Use w ar m w ater , a soft-bristled br ush, and

a mild deterg ent as necessar y to clean the

flo wmeter body and paddle wheel. R emo v e

any small metallic debris .

Important: Do not use solv ents or fuel

to clean the flo wmeter .

5. Install the paddle wheel assembly into the

flo wmeter body .

Important: T he paddle wheel assembl y

will onl y fit into the body one w ay , in a

detent slot on the side of the body . Do not

f orce the paddle wheel assembl y into the

body in an y other orientation.

6. Install the retaining cap .

7. Connect the wire to the flo wmeter .

Cleaning the Suction

Strainer

Clean the suction strainer daily . If y ou are using

w etable po w ders , clean it after ev er y tank.

1. R emo v e the retainer from the red fitting

attac hed to the larg e hose on the top of the

tank.

59

Loading...

Loading...